Solid copper offers excellent electrical conductivity and corrosion resistance, making it ideal for applications requiring high purity and performance. Copper alloys, which combine copper with other metals like zinc or tin, enhance mechanical strength and wear resistance while maintaining good conductivity. Choosing between solid copper and copper alloy depends on the balance needed between durability and electrical or thermal efficiency.

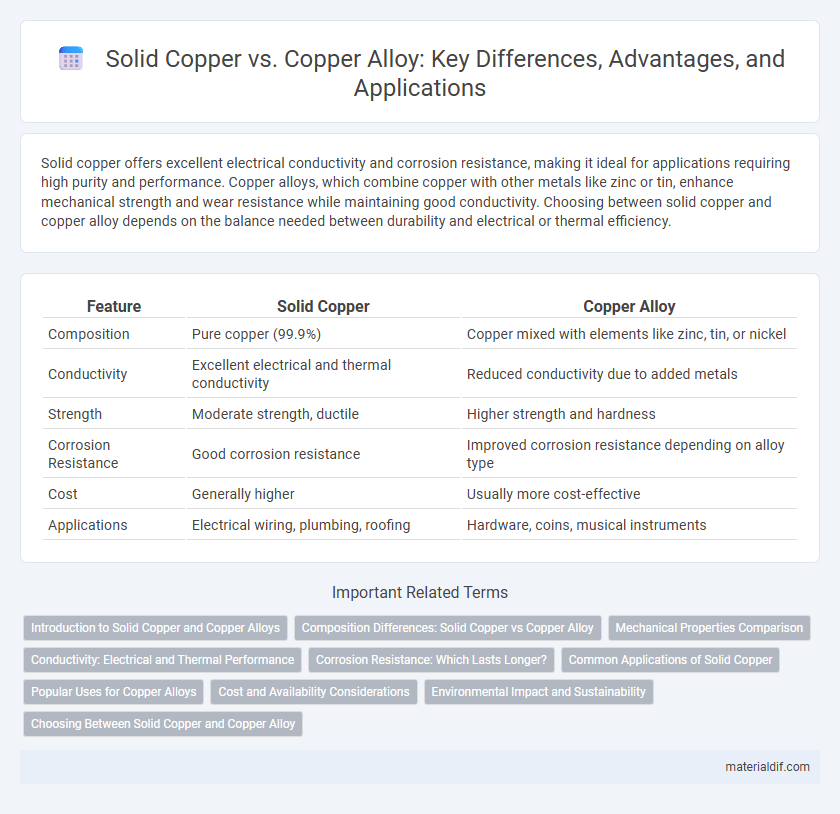

Table of Comparison

| Feature | Solid Copper | Copper Alloy |

|---|---|---|

| Composition | Pure copper (99.9%) | Copper mixed with elements like zinc, tin, or nickel |

| Conductivity | Excellent electrical and thermal conductivity | Reduced conductivity due to added metals |

| Strength | Moderate strength, ductile | Higher strength and hardness |

| Corrosion Resistance | Good corrosion resistance | Improved corrosion resistance depending on alloy type |

| Cost | Generally higher | Usually more cost-effective |

| Applications | Electrical wiring, plumbing, roofing | Hardware, coins, musical instruments |

Introduction to Solid Copper and Copper Alloys

Solid copper is a pure metallic element known for its high electrical and thermal conductivity, corrosion resistance, and malleability, making it essential in electrical wiring, plumbing, and industrial machinery. Copper alloys, which combine copper with other metals such as zinc, tin, or nickel, offer enhanced mechanical strength, improved corrosion resistance, and better wear properties, catering to applications requiring greater durability. Understanding the distinction between solid copper and various copper alloys helps in selecting the appropriate material based on conductivity, strength, and environmental exposure needs.

Composition Differences: Solid Copper vs Copper Alloy

Solid copper primarily consists of almost 100% pure copper, typically with a purity level of 99.9%, offering excellent electrical and thermal conductivity. Copper alloys are composed of copper combined with elements such as zinc (in brass), tin (in bronze), or nickel, which enhance mechanical strength, corrosion resistance, and durability. The specific proportions of alloying elements vary depending on the desired properties, making copper alloys suitable for specialized industrial applications where pure copper's softness is a limitation.

Mechanical Properties Comparison

Solid copper exhibits excellent ductility and electrical conductivity but has lower tensile strength and hardness compared to copper alloys. Copper alloys such as bronze and brass enhance mechanical properties, offering higher tensile strength, improved wear resistance, and greater hardness without significantly compromising corrosion resistance. These improved mechanical attributes make copper alloys preferable in applications requiring structural durability and resistance to mechanical stress.

Conductivity: Electrical and Thermal Performance

Solid copper exhibits superior electrical and thermal conductivity compared to most copper alloys due to its pure composition, allowing electrons and heat to flow with minimal resistance. Copper alloys, containing elements such as zinc or tin, generally have reduced conductivity but offer enhanced mechanical strength and corrosion resistance. Optimal selection between solid copper and copper alloys depends on balancing conductivity requirements with durability and application-specific performance needs.

Corrosion Resistance: Which Lasts Longer?

Solid copper exhibits superior corrosion resistance due to its pure elemental composition, which forms a stable, protective patina that inhibits further degradation. Copper alloys, while often designed for enhanced strength or machinability, may contain elements like zinc or nickel that influence their corrosion rates, sometimes reducing durability in harsh environments. Solid copper generally lasts longer in corrosive conditions, especially in marine or industrial settings, making it the preferred choice for applications requiring maximum longevity.

Common Applications of Solid Copper

Solid copper is widely used in electrical wiring, plumbing, and roofing due to its excellent conductivity, corrosion resistance, and malleability. It also dominates applications in heat exchangers and printed circuit boards where high thermal and electrical performance is critical. In contrast to copper alloys, solid copper provides superior antimicrobial properties, making it ideal for medical and hygienic surfaces.

Popular Uses for Copper Alloys

Copper alloys such as bronze and brass are widely used in electrical connectors, plumbing fittings, and marine hardware due to their enhanced strength and corrosion resistance compared to solid copper. These alloys offer superior machinability and durability, making them ideal for architectural applications, musical instruments, and industrial machinery components. The tailored properties of copper alloys enable expanded functionality in environments where solid copper may be less effective or more prone to wear.

Cost and Availability Considerations

Solid copper typically incurs higher costs due to its purity and widespread demand, making it pricier than copper alloys. Copper alloys, composed of copper mixed with metals such as zinc or tin, offer greater availability and cost-effectiveness for industrial applications. Manufacturers often select copper alloys to balance budget constraints with performance requirements, benefiting from their enhanced durability and lower material expenses.

Environmental Impact and Sustainability

Solid copper exhibits superior recyclability and lower environmental impact compared to copper alloys, as it contains fewer additives that complicate the recycling process. Copper alloys often involve metals like zinc, tin, or nickel, which increase energy consumption and emissions during extraction and refining. Sustainable practices prioritize using solid copper to minimize resource depletion and promote a circular economy through efficient material recovery.

Choosing Between Solid Copper and Copper Alloy

Solid copper offers superior electrical conductivity and corrosion resistance, making it ideal for high-performance electrical components and plumbing applications. Copper alloys, such as brass and bronze, provide enhanced strength, durability, and machinability, suitable for mechanical parts and decorative elements. Selecting between solid copper and copper alloy depends on the required balance of conductivity, strength, and environmental exposure in the intended application.

Solid Copper vs Copper Alloy Infographic

materialdif.com

materialdif.com