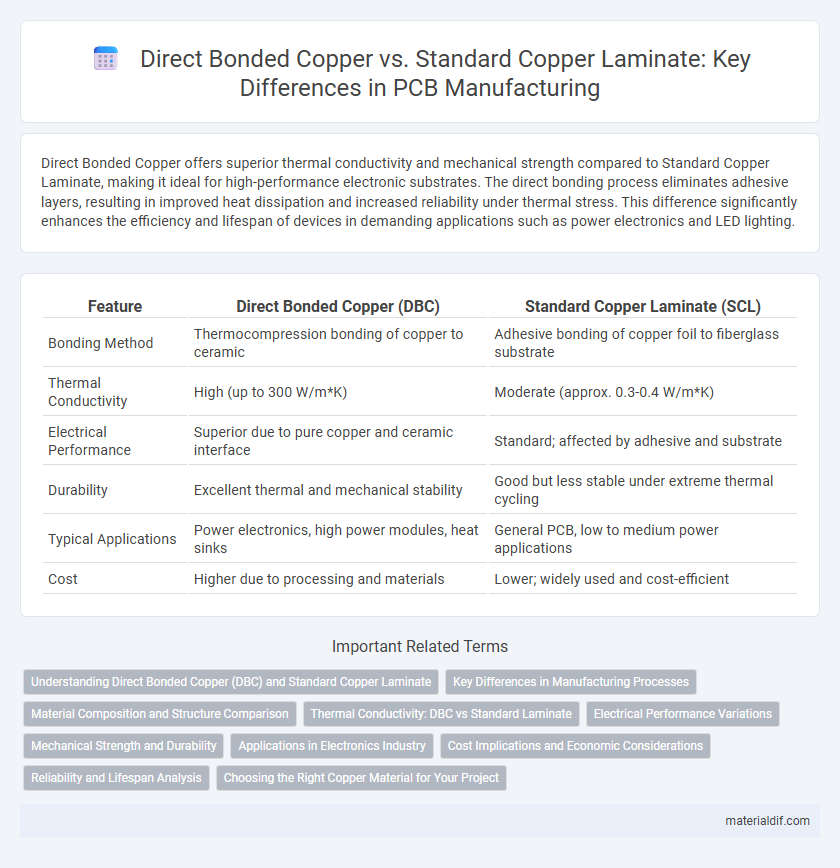

Direct Bonded Copper offers superior thermal conductivity and mechanical strength compared to Standard Copper Laminate, making it ideal for high-performance electronic substrates. The direct bonding process eliminates adhesive layers, resulting in improved heat dissipation and increased reliability under thermal stress. This difference significantly enhances the efficiency and lifespan of devices in demanding applications such as power electronics and LED lighting.

Table of Comparison

| Feature | Direct Bonded Copper (DBC) | Standard Copper Laminate (SCL) |

|---|---|---|

| Bonding Method | Thermocompression bonding of copper to ceramic | Adhesive bonding of copper foil to fiberglass substrate |

| Thermal Conductivity | High (up to 300 W/m*K) | Moderate (approx. 0.3-0.4 W/m*K) |

| Electrical Performance | Superior due to pure copper and ceramic interface | Standard; affected by adhesive and substrate |

| Durability | Excellent thermal and mechanical stability | Good but less stable under extreme thermal cycling |

| Typical Applications | Power electronics, high power modules, heat sinks | General PCB, low to medium power applications |

| Cost | Higher due to processing and materials | Lower; widely used and cost-efficient |

Understanding Direct Bonded Copper (DBC) and Standard Copper Laminate

Direct Bonded Copper (DBC) is a high-performance material combining copper and ceramic, offering superior thermal conductivity and mechanical stability, ideal for power electronics and high-temperature applications. Standard Copper Laminate (SCL) typically consists of copper foil laminated on fiberglass or resin substrates, providing cost-effective, versatile electrical insulation but lower heat dissipation compared to DBC. Understanding the distinct thermal, electrical, and mechanical properties of DBC versus SCL is crucial for optimizing design choices in electronics manufacturing and thermal management solutions.

Key Differences in Manufacturing Processes

Direct bonded copper (DBC) utilizes a high-temperature bonding process where copper is directly fused onto a ceramic substrate, creating excellent thermal conductivity and mechanical strength. Standard copper laminate involves bonding copper foil to a resin-based substrate using adhesive layers, resulting in easier processing but lower heat dissipation and mechanical stability. The key manufacturing difference lies in DBC's metal-ceramic metallurgical bond versus the adhesive bond found in standard copper laminates, impacting thermal performance and reliability in electronic applications.

Material Composition and Structure Comparison

Direct Bonded Copper (DBC) features a pure copper layer directly bonded to a ceramic substrate, providing superior thermal conductivity and mechanical stability compared to Standard Copper Laminate, which consists of copper foil laminated onto fiberglass or other insulating materials. The DBC process eliminates adhesive layers, enhancing heat dissipation and electrical performance in high-power applications. Standard Copper Laminates typically exhibit lower thermal conductivity and may suffer from delamination under thermal stress due to the polymer-based bonding layers.

Thermal Conductivity: DBC vs Standard Laminate

Direct Bonded Copper (DBC) exhibits significantly higher thermal conductivity compared to standard copper laminate due to its direct metallurgical bond between the copper foil and ceramic substrate, minimizing interface thermal resistance. This superior heat dissipation characteristic in DBC is critical for high-power electronics and power modules where efficient thermal management is essential. Standard copper laminates typically show lower thermal conductivity as the bonding involves polymer or adhesive layers that impede effective heat transfer.

Electrical Performance Variations

Direct Bonded Copper (DBC) offers superior electrical performance compared to Standard Copper Laminate due to its lower electrical resistance and higher thermal conductivity, which enhances heat dissipation and signal integrity. The strong metallurgical bond in DBC reduces contact resistance and improves current carrying capacity, making it ideal for high-power and high-frequency applications. Standard Copper Laminates may exhibit higher losses and reduced efficiency in demanding electrical environments due to less effective heat management and potential delamination risks.

Mechanical Strength and Durability

Direct Bonded Copper (DBC) offers superior mechanical strength and durability compared to Standard Copper Laminate due to its sintered bond directly to ceramic substrates, minimizing delamination risks under thermal stress. DBC's enhanced heat dissipation properties contribute to less thermal fatigue, ensuring longer lifecycle in high-power and high-temperature applications. Standard Copper Laminate, while cost-effective, often suffers from weaker adhesion and reduced reliability over time in demanding mechanical environments.

Applications in Electronics Industry

Direct Bonded Copper (DBC) offers superior thermal conductivity and electrical performance compared to Standard Copper Laminate, making it ideal for high-power semiconductor devices and LEDs. Its ability to withstand high temperatures and provide efficient heat dissipation enhances reliability in electronic circuits found in power modules, automotive electronics, and RF applications. Standard Copper Laminates are commonly used for general printed circuit boards (PCBs) due to cost-effectiveness but lack the advanced thermal management required in high-performance electronics.

Cost Implications and Economic Considerations

Direct Bonded Copper (DBC) offers superior thermal conductivity and reliability but comes with higher manufacturing costs compared to Standard Copper Laminate (SCL), impacting overall project budgets. While SCL provides a cost-effective solution ideal for applications with moderate thermal requirements, DBC's enhanced performance justifies its price premium in high-power electronics where long-term savings from reduced failures and maintenance are critical. Economic considerations must balance initial material expense against lifecycle benefits to determine the best copper technology for specific industrial applications.

Reliability and Lifespan Analysis

Direct Bonded Copper (DBC) offers superior reliability and lifespan compared to Standard Copper Laminate due to its enhanced thermal conductivity and strong adhesion to ceramic substrates, reducing thermal stress and delamination risks. The robust metallurgical bond in DBC minimizes oxidation and mechanical failure under high-temperature cycling, extending operational durability in power electronics and high-frequency applications. In contrast, Standard Copper Laminate is more prone to thermal fatigue and interface degradation, leading to reduced long-term performance and increased maintenance costs.

Choosing the Right Copper Material for Your Project

Direct Bonded Copper (DBC) offers superior thermal conductivity and mechanical stability compared to Standard Copper Laminate, making it ideal for high-power electronics and LED applications. Standard Copper Laminate provides flexibility and cost-effectiveness for general-purpose printed circuit boards, benefiting projects with lower thermal demands. Selecting the right copper material depends on balancing thermal performance requirements, budget constraints, and specific application needs.

Direct Bonded Copper vs Standard Copper Laminate Infographic

materialdif.com

materialdif.com