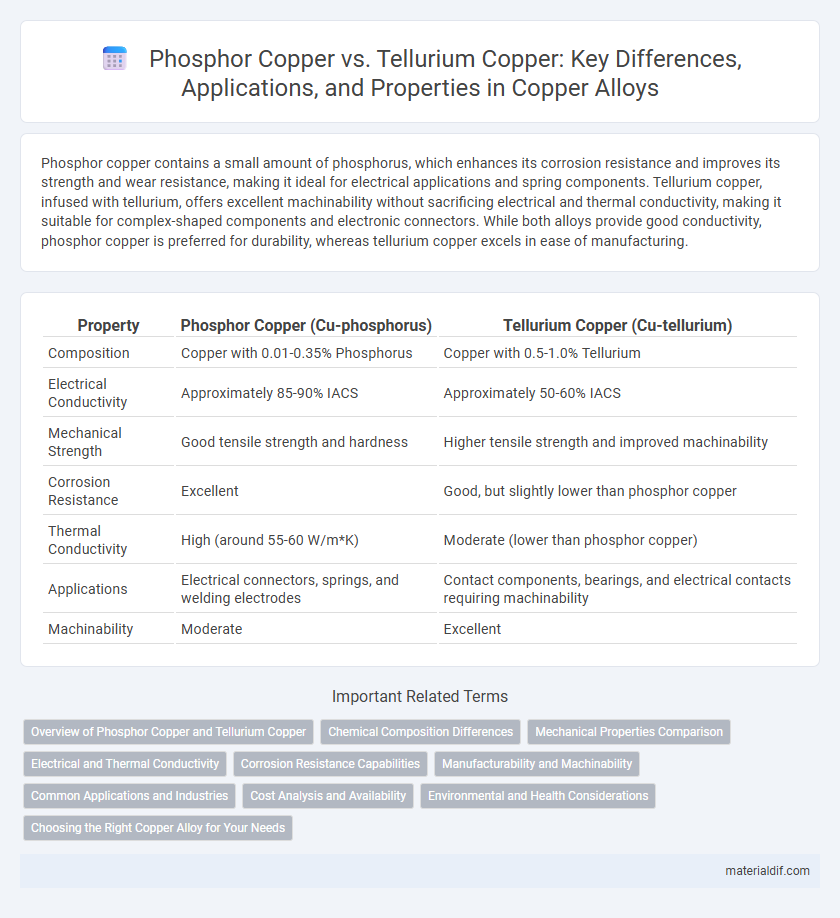

Phosphor copper contains a small amount of phosphorus, which enhances its corrosion resistance and improves its strength and wear resistance, making it ideal for electrical applications and spring components. Tellurium copper, infused with tellurium, offers excellent machinability without sacrificing electrical and thermal conductivity, making it suitable for complex-shaped components and electronic connectors. While both alloys provide good conductivity, phosphor copper is preferred for durability, whereas tellurium copper excels in ease of manufacturing.

Table of Comparison

| Property | Phosphor Copper (Cu-phosphorus) | Tellurium Copper (Cu-tellurium) |

|---|---|---|

| Composition | Copper with 0.01-0.35% Phosphorus | Copper with 0.5-1.0% Tellurium |

| Electrical Conductivity | Approximately 85-90% IACS | Approximately 50-60% IACS |

| Mechanical Strength | Good tensile strength and hardness | Higher tensile strength and improved machinability |

| Corrosion Resistance | Excellent | Good, but slightly lower than phosphor copper |

| Thermal Conductivity | High (around 55-60 W/m*K) | Moderate (lower than phosphor copper) |

| Applications | Electrical connectors, springs, and welding electrodes | Contact components, bearings, and electrical contacts requiring machinability |

| Machinability | Moderate | Excellent |

Overview of Phosphor Copper and Tellurium Copper

Phosphor copper is primarily an alloy of copper with phosphorus, known for its excellent wear resistance, high strength, and superior corrosion resistance, making it suitable for electrical applications and precision instruments. Tellurium copper contains a small amount of tellurium to improve machinability without significantly compromising electrical conductivity, often used in electrical connectors and industrial equipment. Both alloys enhance copper's mechanical properties, but phosphor copper emphasizes strength and durability, while tellurium copper is favored for ease of fabrication.

Chemical Composition Differences

Phosphor copper contains a small percentage of phosphorus, typically around 0.01-0.35%, which improves its corrosion resistance and mechanical strength by refining the grain structure. Tellurium copper, on the other hand, includes approximately 0.5-0.75% tellurium, enhancing machinability without compromising electrical conductivity. The key chemical difference lies in the alloying element--phosphorus in phosphor copper versus tellurium in tellurium copper--impacting their respective physical properties and applications.

Mechanical Properties Comparison

Phosphor copper exhibits superior strength and wear resistance compared to tellurium copper due to its higher phosphorus content, which enhances hardness and tensile strength. Tellurium copper offers better machinability and electrical conductivity but generally has lower yield strength and ductility relative to phosphor copper. The mechanical properties of phosphor copper make it ideal for applications requiring durability and resistance to deformation under stress.

Electrical and Thermal Conductivity

Phosphor copper (C15200) offers superior electrical conductivity, typically around 96% IACS, while tellurium copper (C14500) has slightly lower electrical conductivity, approximately 80-85% IACS. In terms of thermal conductivity, phosphor copper excels with values close to 220 W/m*K, making it ideal for heat dissipation applications, whereas tellurium copper possesses moderate thermal conductivity near 150 W/m*K, balancing machinability and conductivity. Both alloys are used in electrical components, but phosphor copper is preferred for high conductivity and thermal performance, while tellurium copper is favored when improved machinability is prioritized.

Corrosion Resistance Capabilities

Phosphor copper exhibits superior corrosion resistance due to its phosphorus content, which enhances its ability to withstand oxidation and chemical exposure in marine and industrial environments. Tellurium copper offers moderate corrosion resistance but is primarily valued for improved machinability rather than protection against corrosive elements. Both alloys maintain good overall durability, but phosphor copper is preferred for applications requiring longer service life in harsh conditions.

Manufacturability and Machinability

Phosphor copper offers excellent manufacturability due to its high strength and good corrosion resistance, making it suitable for applications requiring complex forming and welding processes. Tellurium copper provides superior machinability with enhanced chip-breaking properties, reducing tool wear and enabling faster machining speeds compared to phosphor copper. Both alloys balance performance and ease of fabrication, but tellurium copper is preferred for precision machining while phosphor copper excels in structural and electrical applications.

Common Applications and Industries

Phosphor copper is widely used in electrical connectors and precision springs due to its excellent conductivity and corrosion resistance, making it ideal for the electronics and telecommunications industries. Tellurium copper is favored for machining applications such as electrical switches and automotive components because of its superior machinability combined with good conductivity. Both alloys find critical roles in industrial manufacturing, but phosphor copper is preferred for high-performance electrical applications, while tellurium copper is dominant in mechanical parts requiring easier fabrication.

Cost Analysis and Availability

Phosphor copper generally has a lower cost compared to tellurium copper due to its simpler production process and higher availability in raw materials. Tellurium copper offers superior machinability and strength but comes with a higher price point influenced by the scarcity of tellurium. The abundant supply of phosphor copper makes it a more economical choice for large-scale applications requiring good conductivity and moderate mechanical properties.

Environmental and Health Considerations

Phosphor copper contains a small amount of phosphorus, which improves corrosion resistance but may pose minimal environmental risks during mining and refining. Tellurium copper incorporates tellurium to enhance machinability, yet tellurium compounds can be toxic if improperly handled, requiring stringent safety and disposal measures. Both alloys demand careful management to minimize environmental impact and ensure worker health, emphasizing the importance of regulatory compliance and protective equipment.

Choosing the Right Copper Alloy for Your Needs

Phosphor copper offers excellent electrical conductivity and superior corrosion resistance, making it ideal for electrical connectors and marine applications. Tellurium copper, with enhanced machinability and strength, suits precision components such as switchgear and welding electrodes. Selecting the right copper alloy depends on balancing conductivity requirements and mechanical properties tailored to your specific industrial application.

Phosphor Copper vs Tellurium Copper Infographic

materialdif.com

materialdif.com