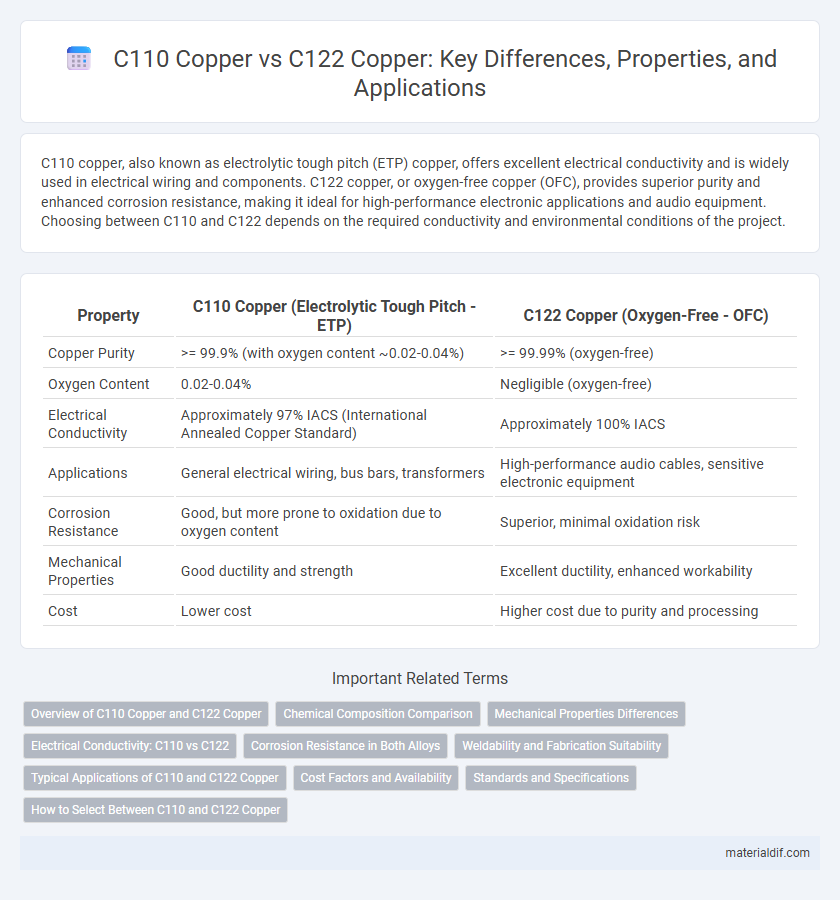

C110 copper, also known as electrolytic tough pitch (ETP) copper, offers excellent electrical conductivity and is widely used in electrical wiring and components. C122 copper, or oxygen-free copper (OFC), provides superior purity and enhanced corrosion resistance, making it ideal for high-performance electronic applications and audio equipment. Choosing between C110 and C122 depends on the required conductivity and environmental conditions of the project.

Table of Comparison

| Property | C110 Copper (Electrolytic Tough Pitch - ETP) | C122 Copper (Oxygen-Free - OFC) |

|---|---|---|

| Copper Purity | >= 99.9% (with oxygen content ~0.02-0.04%) | >= 99.99% (oxygen-free) |

| Oxygen Content | 0.02-0.04% | Negligible (oxygen-free) |

| Electrical Conductivity | Approximately 97% IACS (International Annealed Copper Standard) | Approximately 100% IACS |

| Applications | General electrical wiring, bus bars, transformers | High-performance audio cables, sensitive electronic equipment |

| Corrosion Resistance | Good, but more prone to oxidation due to oxygen content | Superior, minimal oxidation risk |

| Mechanical Properties | Good ductility and strength | Excellent ductility, enhanced workability |

| Cost | Lower cost | Higher cost due to purity and processing |

Overview of C110 Copper and C122 Copper

C110 Copper, also known as Electrolytic Tough Pitch (ETP) copper, is characterized by its high electrical conductivity of approximately 100% IACS and is widely used in electrical applications due to its excellent thermal and electrical properties. C122 Copper, commonly referred to as Oxygen-Free Electronic (OFE) copper, offers superior purity with a minimum copper content of 99.99%, resulting in enhanced mechanical strength and corrosion resistance compared to C110. Both C110 and C122 coppers serve critical functions in electronics and industrial components but differ primarily in oxygen content and purity levels, impacting their performance and suitability for specific applications.

Chemical Composition Comparison

C110 copper, also known as electrolytic tough pitch (ETP) copper, primarily contains 99.9% pure copper with a small oxygen content around 0.02% to 0.04%, enhancing electrical conductivity. In contrast, C122 copper, or oxygen-free electronic (OFE) copper, has a significantly lower oxygen content, less than 0.0005%, due to its production in a controlled atmosphere, resulting in superior purity and corrosion resistance. The distinct chemical compositions influence C110's suitability for general electrical applications, while C122 is preferred for high-performance electronic components requiring minimal oxygen impurities.

Mechanical Properties Differences

C110 Copper, also known as electrolytic tough pitch (ETP) copper, exhibits higher electrical conductivity but lower strength compared to C122 Copper, a high-conductivity tough pitch copper variant. Mechanical properties of C122 Copper display improved tensile strength and hardness due to its refined grain structure and controlled impurity levels, making it suitable for applications requiring enhanced durability. The increased mechanical strength of C122 Copper supports better performance under stress, whereas C110 is preferred for electrical applications demanding maximum conductivity.

Electrical Conductivity: C110 vs C122

C110 copper, also known as electrolytic tough pitch (ETP) copper, exhibits higher electrical conductivity, typically around 101% IACS (International Annealed Copper Standard), making it ideal for electrical applications requiring excellent current flow. C122 copper contains a small amount of silver, which slightly reduces its conductivity to approximately 98-99% IACS, but improves its strength and resistance to stress corrosion. For applications where maximum electrical conductivity is critical, C110 copper is generally preferred over C122 copper.

Corrosion Resistance in Both Alloys

C110 Copper, also known as Electrolytic Tough Pitch (ETP) copper, exhibits excellent corrosion resistance in atmospheric and industrial environments due to its high purity and oxygen content. C122 Copper, an oxygen-free copper variant, offers superior corrosion resistance in reducing environments and high-frequency applications by minimizing hydrogen embrittlement and intergranular attack. Both alloys provide reliable corrosion protection, with C122 better suited for applications demanding enhanced durability against aggressive chemicals and extreme conditions.

Weldability and Fabrication Suitability

C110 copper, known as electrolytic tough pitch (ETP) copper, offers excellent weldability due to its high purity and consistent electrical conductivity, making it ideal for electrical applications requiring precise fabrication. C122 copper, or oxygen-free copper (OFC), provides superior weld quality with minimal porosity, suitable for critical vacuum and aerospace components where fabrication precision is paramount. Both alloys exhibit good machinability, but C122's lower oxygen content enhances its performance in sensitive weld and fabrication processes.

Typical Applications of C110 and C122 Copper

C110 copper is widely used in electrical connectors, terminals, and precision electronic components due to its excellent electrical conductivity and workability. C122 copper, containing a small addition of phosphorus, is favored for plumbing and heating applications because of its enhanced corrosion resistance and strength. Both alloys serve critical roles in industry, with C110 preferred for electrical uses and C122 optimized for mechanical and plumbing systems.

Cost Factors and Availability

C110 copper, also known as electrolytic tough pitch (ETP) copper, generally costs less than C122 copper due to its higher purity and widespread availability in the market. C122 copper, with a small addition of phosphorus for improved corrosion resistance and thermal stability, typically commands a higher price because of its specialized properties and more limited production. Availability impacts cost significantly, as C110 is more commonly produced and stocked globally, whereas C122's niche applications result in lower inventory and potentially higher lead times.

Standards and Specifications

C110 copper, also known as Electrolytic Tough Pitch (ETP) copper, complies with ASTM B170 and UNS C11000 standards, emphasizing high electrical conductivity for electrical applications. C122 copper, referred to as Oxygen-Free High Conductivity (OFHC) copper, meets ASTM B187 and BS EN 1652 standards, noted for superior purity and improved thermal conductivity in high-performance electronic components. Both types adhere to strict international specifications, with C122 copper offering enhanced mechanical properties and reduced oxygen content compared to C110 copper.

How to Select Between C110 and C122 Copper

Selecting between C110 and C122 copper depends on the specific application requirements and mechanical properties needed. C110 copper offers exceptional electrical conductivity and excellent workability, making it ideal for electrical and electronic components, while C122 copper provides higher strength and improved corrosion resistance due to its alloyed composition, suitable for structural and marine applications. Evaluate environmental exposure, mechanical stress, and conductivity demands to determine the optimal copper grade for your project.

C110 Copper vs C122 Copper Infographic

materialdif.com

materialdif.com