Copper tubing offers greater flexibility and is typically used for residential water supply lines, while copper piping is more rigid and preferred for structural applications. Tubing is measured by outside diameter and is easier to install in tight spaces, whereas piping is measured by nominal pipe size and provides higher durability for industrial use. Both options provide excellent corrosion resistance and thermal conductivity, making them ideal for plumbing and HVAC systems.

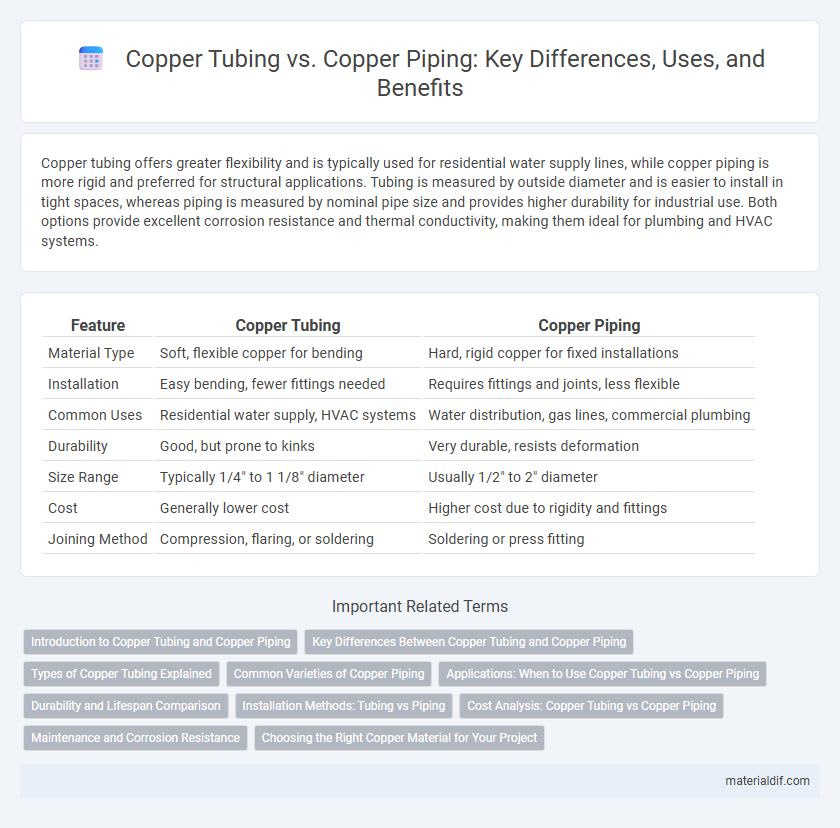

Table of Comparison

| Feature | Copper Tubing | Copper Piping |

|---|---|---|

| Material Type | Soft, flexible copper for bending | Hard, rigid copper for fixed installations |

| Installation | Easy bending, fewer fittings needed | Requires fittings and joints, less flexible |

| Common Uses | Residential water supply, HVAC systems | Water distribution, gas lines, commercial plumbing |

| Durability | Good, but prone to kinks | Very durable, resists deformation |

| Size Range | Typically 1/4" to 1 1/8" diameter | Usually 1/2" to 2" diameter |

| Cost | Generally lower cost | Higher cost due to rigidity and fittings |

| Joining Method | Compression, flaring, or soldering | Soldering or press fitting |

Introduction to Copper Tubing and Copper Piping

Copper tubing and copper piping are essential materials in plumbing and HVAC systems, each designed for specific applications based on diameter and flexibility. Copper tubing is typically smaller in diameter, flexible, and used for refrigeration, gas, and water supply lines, while copper piping is thicker, rigid, and ideal for structural water and gas conveyance. Both offer excellent corrosion resistance, thermal conductivity, and durability, making them reliable choices in residential and commercial installations.

Key Differences Between Copper Tubing and Copper Piping

Copper tubing is typically seamless and flexible, making it ideal for refrigeration and medical gas systems, while copper piping is often rigid and used in plumbing and water supply applications. The thickness of the walls differs, with tubing generally having thinner walls than piping, affecting pressure tolerance and installation methods. Copper piping is sized by nominal pipe size (NPS), whereas copper tubing is measured by outside diameter (OD), which impacts fittings and connections.

Types of Copper Tubing Explained

Copper tubing primarily includes soft and rigid types, each tailored for specific plumbing and HVAC applications. Soft copper tubing is annealed for flexibility, ideal for bending around corners and connecting appliances, while rigid copper pipes provide structural integrity for water supply lines and gas distribution. Understanding these types ensures proper material selection based on durability, installation ease, and system requirements.

Common Varieties of Copper Piping

Common varieties of copper piping include Type K, Type L, Type M, and DWV, each distinguished by wall thickness and application suitability. Type K features the thickest walls, making it ideal for underground or high-pressure water systems, while Type L is widely used for interior plumbing due to its balanced durability and cost. Type M is thinner and more affordable but suitable only for low-pressure applications; DWV piping is specifically designed for drainage, waste, and vent systems requiring corrosion resistance.

Applications: When to Use Copper Tubing vs Copper Piping

Copper tubing is ideal for refrigeration, air conditioning, and plumbing systems requiring flexibility and precise fittings, often used in residential water supply lines and HVAC installations. Copper piping is preferred for high-pressure applications, such as gas lines and industrial plumbing, due to its thicker walls and durability. Choosing between copper tubing and piping depends on the application's pressure requirements, installation complexity, and whether rigidity or flexibility is needed.

Durability and Lifespan Comparison

Copper tubing offers superior durability and flexibility compared to copper piping, making it less prone to cracks and leaks under pressure or temperature changes. The lifespan of copper tubing typically ranges from 50 to 70 years, whereas copper piping lasts around 40 to 50 years due to its rigid structure and susceptibility to damage during installation. Both materials resist corrosion well, but copper tubing's enhanced resilience often results in longer service life in plumbing and HVAC systems.

Installation Methods: Tubing vs Piping

Copper tubing offers greater flexibility, allowing it to be bent easily during installation, which reduces the need for additional fittings and speeds up the process. Copper piping, typically rigid and measured by nominal pipe size (NPS), requires precise cutting and more fittings such as elbows and joints to navigate around obstacles. Choosing between copper tubing and piping depends on the specific installation environment, with tubing favored for tight spaces and piping preferred for standardized, durable setups.

Cost Analysis: Copper Tubing vs Copper Piping

Copper tubing typically incurs a lower installation cost due to its flexibility, which reduces the need for fittings and labor expenses compared to rigid copper piping. Material costs can vary, with tubing often priced slightly higher per foot, but the overall project cost favors tubing when factoring in reduced labor and fewer joints. Maintenance expenses also tend to be lower for tubing, as its continuous lengths minimize leak points common in piping systems.

Maintenance and Corrosion Resistance

Copper tubing offers superior flexibility and ease of installation compared to copper piping, reducing maintenance demands over time. Its seamless construction minimizes corrosion risks, enhancing longevity in plumbing and HVAC systems. Copper piping, while sturdier, can be more prone to joint leaks and requires periodic inspection to prevent corrosion buildup.

Choosing the Right Copper Material for Your Project

Copper tubing offers flexibility and is ideal for tight bends in residential plumbing, while copper piping provides greater durability and is preferred for commercial or industrial applications. Choosing the right copper material depends on factors like environment, pressure requirements, and installation complexity. Opt for Type L copper tubing for moderate pressure systems and Type K copper piping for high-pressure or underground installations to ensure long-lasting performance.

Copper Tubing vs Copper Piping Infographic

materialdif.com

materialdif.com