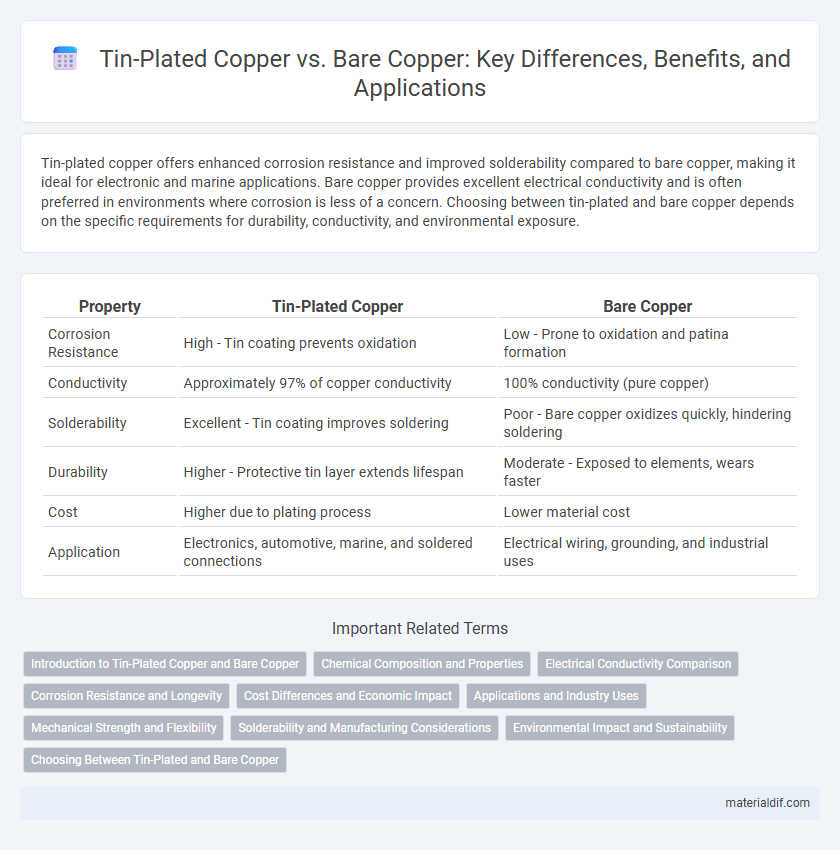

Tin-plated copper offers enhanced corrosion resistance and improved solderability compared to bare copper, making it ideal for electronic and marine applications. Bare copper provides excellent electrical conductivity and is often preferred in environments where corrosion is less of a concern. Choosing between tin-plated and bare copper depends on the specific requirements for durability, conductivity, and environmental exposure.

Table of Comparison

| Property | Tin-Plated Copper | Bare Copper |

|---|---|---|

| Corrosion Resistance | High - Tin coating prevents oxidation | Low - Prone to oxidation and patina formation |

| Conductivity | Approximately 97% of copper conductivity | 100% conductivity (pure copper) |

| Solderability | Excellent - Tin coating improves soldering | Poor - Bare copper oxidizes quickly, hindering soldering |

| Durability | Higher - Protective tin layer extends lifespan | Moderate - Exposed to elements, wears faster |

| Cost | Higher due to plating process | Lower material cost |

| Application | Electronics, automotive, marine, and soldered connections | Electrical wiring, grounding, and industrial uses |

Introduction to Tin-Plated Copper and Bare Copper

Tin-plated copper consists of a copper base coated with a layer of tin to enhance corrosion resistance and solderability, widely used in electrical connectors and printed circuit boards. Bare copper, characterized by its high electrical conductivity and thermal efficiency, is favored in applications requiring low resistance without additional surface treatments. The tin plating provides protection against oxidation, extending the lifespan of copper components in harsh environments while maintaining reliable electrical performance.

Chemical Composition and Properties

Tin-plated copper consists of a copper base coated with a thin layer of tin, enhancing corrosion resistance and solderability compared to bare copper. Bare copper is pure elemental copper known for excellent electrical conductivity and ductility but is prone to oxidation and corrosion in harsh environments. The tin coating provides a protective barrier that maintains conductivity while improving surface durability and longevity in industrial applications.

Electrical Conductivity Comparison

Tin-plated copper maintains approximately 97% to 99% of the electrical conductivity of bare copper, providing excellent corrosion resistance while preserving efficient current flow. Bare copper exhibits the highest electrical conductivity, typically around 5.8 x 10^7 S/m, making it the preferred choice for applications demanding maximum conductivity. Selecting tin-plated copper balances conductivity with enhanced durability in environments prone to oxidation and contact wear.

Corrosion Resistance and Longevity

Tin-plated copper offers superior corrosion resistance compared to bare copper by forming a protective tin layer that prevents oxidation and tarnishing, making it ideal for harsh environments. This tin coating extends the longevity of copper components by reducing the risk of pitting and galvanic corrosion, especially in marine or industrial applications. Bare copper, while highly conductive, tends to oxidize over time, leading to reduced efficiency and shorter service life without protective treatment.

Cost Differences and Economic Impact

Tin-plated copper incurs higher initial costs compared to bare copper due to the additional coating process and materials, yet it offers enhanced corrosion resistance, reducing long-term maintenance expenses. Bare copper remains more economical upfront, favored in applications prioritizing cost-efficiency over durability. The economic impact varies by industry, with tin-plated copper preferred in harsh environments to minimize replacement frequency and associated downtime costs.

Applications and Industry Uses

Tin-plated copper offers enhanced corrosion resistance and solderability, making it ideal for electrical connectors, marine equipment, and printed circuit boards where durability and conductivity are critical. Bare copper is widely used in power generation, telecommunications, and building wiring due to its excellent electrical and thermal conductivity but requires protective coatings in harsh environments. Industries like automotive and aerospace prefer tin-plated copper for long-lasting performance in moisture-prone or chemically aggressive conditions.

Mechanical Strength and Flexibility

Tin-plated copper offers enhanced corrosion resistance and maintains good mechanical strength, making it suitable for applications requiring durability and environmental protection. Bare copper exhibits superior flexibility and electrical conductivity but is more prone to oxidation and physical wear over time. Selecting between tin-plated and bare copper depends on the balance needed between mechanical strength, flexibility, and environmental exposure.

Solderability and Manufacturing Considerations

Tin-plated copper offers superior solderability compared to bare copper due to its corrosion-resistant tin coating, which creates a more reliable, oxidization-free surface for solder joints. Manufacturing processes benefit from tin-plated copper by reducing the need for cleaning and improving joint consistency, while bare copper requires additional surface preparation to prevent oxidation during soldering. Despite the higher cost of tin plating, its enhancement in solder joint quality and manufacturing efficiency often justifies the investment for electronics and electrical applications.

Environmental Impact and Sustainability

Tin-plated copper offers enhanced corrosion resistance, reducing the need for frequent replacements and minimizing environmental waste compared to bare copper. The plating process involves additional chemicals but extends the lifespan of copper products, leading to improved sustainability in long-term applications. Bare copper, while fully recyclable, can degrade faster in harsh environments, potentially increasing material consumption and environmental impact.

Choosing Between Tin-Plated and Bare Copper

Choosing between tin-plated copper and bare copper depends on factors like corrosion resistance, conductivity, and cost. Tin-plated copper offers enhanced resistance to oxidation and solderability, making it ideal for harsh environments and electronic applications. Bare copper provides superior electrical conductivity and is preferred in applications where maximum current flow and cost efficiency are critical.

Tin-Plated Copper vs Bare Copper Infographic

materialdif.com

materialdif.com