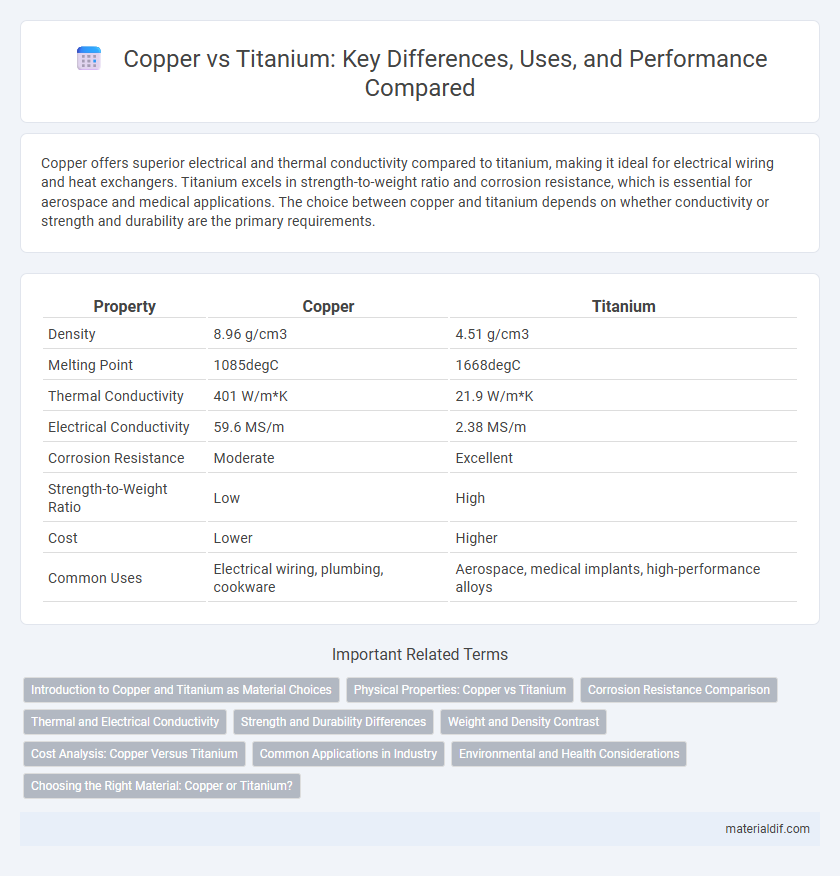

Copper offers superior electrical and thermal conductivity compared to titanium, making it ideal for electrical wiring and heat exchangers. Titanium excels in strength-to-weight ratio and corrosion resistance, which is essential for aerospace and medical applications. The choice between copper and titanium depends on whether conductivity or strength and durability are the primary requirements.

Table of Comparison

| Property | Copper | Titanium |

|---|---|---|

| Density | 8.96 g/cm3 | 4.51 g/cm3 |

| Melting Point | 1085degC | 1668degC |

| Thermal Conductivity | 401 W/m*K | 21.9 W/m*K |

| Electrical Conductivity | 59.6 MS/m | 2.38 MS/m |

| Corrosion Resistance | Moderate | Excellent |

| Strength-to-Weight Ratio | Low | High |

| Cost | Lower | Higher |

| Common Uses | Electrical wiring, plumbing, cookware | Aerospace, medical implants, high-performance alloys |

Introduction to Copper and Titanium as Material Choices

Copper exhibits excellent electrical conductivity, corrosion resistance, and thermal properties, making it ideal for electrical wiring, plumbing, and heat exchangers. Titanium offers exceptional strength-to-weight ratio, superior corrosion resistance, and biocompatibility, commonly used in aerospace, medical implants, and high-performance engineering. Comparing these materials highlights copper's efficiency in conductivity applications and titanium's advantage in lightweight, durable structural components.

Physical Properties: Copper vs Titanium

Copper exhibits excellent electrical and thermal conductivity, with a density of 8.96 g/cm3 and a melting point of 1085degC, making it ideal for electrical wiring and heat exchangers. Titanium, significantly lighter with a density of approximately 4.5 g/cm3 and a higher melting point around 1668degC, offers superior strength-to-weight ratio and corrosion resistance. While copper is more ductile and malleable, titanium's exceptional strength and lower thermal conductivity suit aerospace and medical applications requiring lightweight, durable materials.

Corrosion Resistance Comparison

Copper exhibits moderate corrosion resistance, forming a protective green patina over time that shields the metal from further damage, especially in atmospheric and marine environments. Titanium offers superior corrosion resistance due to its stable oxide layer, preventing degradation even in highly aggressive chemical and saltwater conditions. While copper is prone to tarnishing and oxidation, titanium remains largely unaffected, making it the preferred choice for applications requiring long-term durability in corrosive environments.

Thermal and Electrical Conductivity

Copper exhibits superior thermal conductivity at approximately 401 W/mK and electrical conductivity around 5.96 x 10^7 S/m, significantly outperforming titanium, which has a thermal conductivity near 22 W/mK and electrical conductivity about 2.38 x 10^6 S/m. These properties make copper the preferred material for applications requiring efficient heat dissipation and electrical conduction. Titanium's lower conductivity values limit its use in high-performance thermal and electrical systems despite its strength and corrosion resistance.

Strength and Durability Differences

Copper offers excellent ductility and corrosion resistance but has lower tensile strength compared to titanium. Titanium exhibits superior strength-to-weight ratio and exceptional durability under extreme conditions, making it ideal for aerospace and medical applications. The durability of titanium surpasses copper, especially in high-stress and high-temperature environments, ensuring longer material lifespan.

Weight and Density Contrast

Copper has a density of approximately 8.96 g/cm3, making it significantly heavier than titanium, which has a density around 4.51 g/cm3. This density contrast means titanium offers nearly half the weight of copper for the same volume, benefiting applications requiring lightweight and strong materials. The weight advantage of titanium makes it ideal for aerospace and medical devices where reduced mass enhances performance and durability.

Cost Analysis: Copper Versus Titanium

Copper generally exhibits a lower initial cost compared to titanium, making it a more budget-friendly option for projects with tight financial constraints. Titanium offers superior corrosion resistance and strength-to-weight ratio but comes at a significantly higher price point, often two to three times the cost of copper. Long-term cost analysis must consider maintenance expenses, where copper may require more frequent upkeep, potentially offsetting its initial affordability.

Common Applications in Industry

Copper excels in electrical wiring, plumbing, and heat exchangers due to its superior electrical and thermal conductivity, making it indispensable in power generation and telecommunications. Titanium is favored in aerospace, medical implants, and chemical processing for its high strength-to-weight ratio, corrosion resistance, and biocompatibility. While copper dominates in electrical and thermal applications, titanium leads in structural and biomedical industries where durability and lightweight properties are critical.

Environmental and Health Considerations

Copper shows strong antimicrobial properties that reduce the spread of bacteria and viruses, making it beneficial for health-conscious applications. Its high recyclability and natural abundance contribute to lower environmental impact compared to titanium, which requires more energy-intensive mining and refining processes. Although titanium boasts exceptional strength and corrosion resistance, copper's biodegradability and lower toxicity provide distinct environmental and health advantages.

Choosing the Right Material: Copper or Titanium?

Copper offers superior electrical and thermal conductivity, making it ideal for electrical wiring and heat exchangers, while titanium excels in strength-to-weight ratio and corrosion resistance, favored in aerospace and medical implants. When selecting between copper and titanium, consider the application's environmental exposure, mechanical stress, and conductivity requirements to ensure optimal performance and longevity. Cost factors also play a role, as copper is generally more economical, whereas titanium's durability justifies its higher price in demanding environments.

Copper vs Titanium Infographic

materialdif.com

materialdif.com