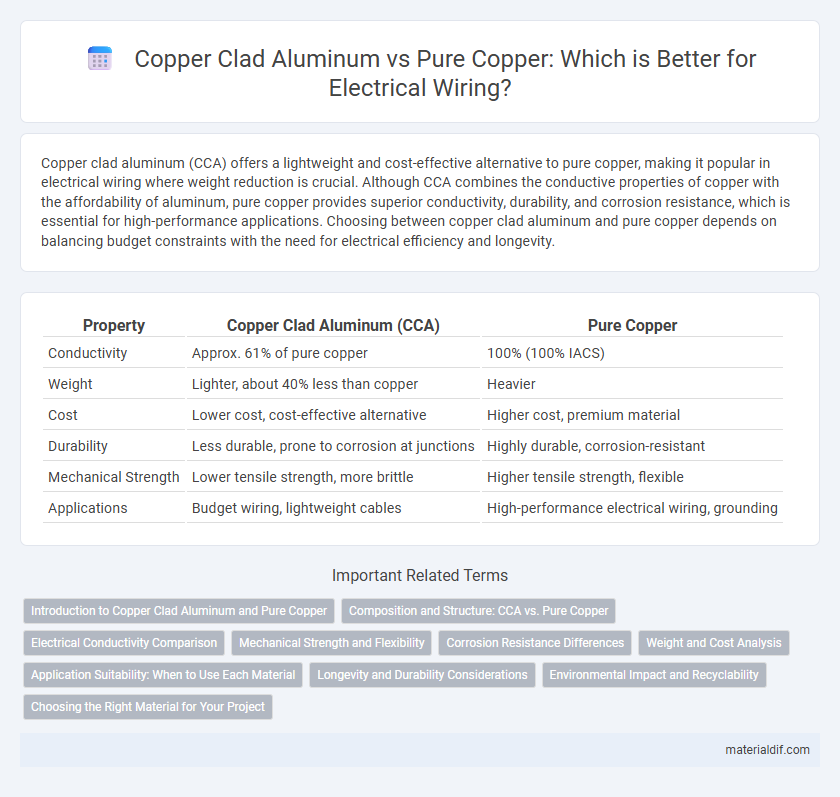

Copper clad aluminum (CCA) offers a lightweight and cost-effective alternative to pure copper, making it popular in electrical wiring where weight reduction is crucial. Although CCA combines the conductive properties of copper with the affordability of aluminum, pure copper provides superior conductivity, durability, and corrosion resistance, which is essential for high-performance applications. Choosing between copper clad aluminum and pure copper depends on balancing budget constraints with the need for electrical efficiency and longevity.

Table of Comparison

| Property | Copper Clad Aluminum (CCA) | Pure Copper |

|---|---|---|

| Conductivity | Approx. 61% of pure copper | 100% (100% IACS) |

| Weight | Lighter, about 40% less than copper | Heavier |

| Cost | Lower cost, cost-effective alternative | Higher cost, premium material |

| Durability | Less durable, prone to corrosion at junctions | Highly durable, corrosion-resistant |

| Mechanical Strength | Lower tensile strength, more brittle | Higher tensile strength, flexible |

| Applications | Budget wiring, lightweight cables | High-performance electrical wiring, grounding |

Introduction to Copper Clad Aluminum and Pure Copper

Copper clad aluminum (CCA) consists of an aluminum core coated with a thin layer of pure copper, offering a lightweight and cost-effective alternative to pure copper while maintaining good conductivity and corrosion resistance. Pure copper, composed entirely of copper, features superior electrical and thermal conductivity, higher tensile strength, and enhanced durability compared to copper clad aluminum. Applications of CCA and pure copper vary based on performance requirements, with CCA commonly used in telecommunications and power cables, whereas pure copper is preferred in high-performance electrical wiring and industrial components.

Composition and Structure: CCA vs. Pure Copper

Copper Clad Aluminum (CCA) consists of an aluminum core coated with a thin layer of pure copper, combining lightweight aluminum with copper's excellent conductivity. Pure copper, on the other hand, is a homogeneous metal with uniform composition, offering superior electrical and thermal conductivity compared to CCA. The structure of CCA provides cost efficiency and reduced weight but typically results in higher resistance and less durability than solid copper.

Electrical Conductivity Comparison

Copper clad aluminum (CCA) has lower electrical conductivity compared to pure copper due to aluminum's higher resistivity; pure copper's conductivity measures approximately 59.6 MS/m, whereas aluminum is around 37.7 MS/m. The combination in CCA reduces weight and cost but results in approximately 61-70% the conductivity of pure copper, impacting performance in high-current applications. Pure copper remains the preferred choice where optimal electrical efficiency and minimal energy loss are critical.

Mechanical Strength and Flexibility

Copper Clad Aluminum (CCA) offers lower mechanical strength compared to Pure Copper, making it more prone to bending and breaking under high stress. Pure Copper exhibits superior flexibility and ductility, allowing it to withstand repeated bending without damage. While CCA is lighter and less expensive, Pure Copper remains the preferred choice for applications requiring durability and long-term reliability.

Corrosion Resistance Differences

Copper Clad Aluminum (CCA) exhibits reduced corrosion resistance compared to pure copper due to the aluminum core's susceptibility to oxidation when exposed to moisture and air. Pure copper forms a stable oxide layer that protects it from further corrosion, enhancing its durability in harsh environments. The disparity in corrosion resistance influences the longevity and performance of electrical conductors, with pure copper preferred in applications demanding superior protection against environmental degradation.

Weight and Cost Analysis

Copper clad aluminum (CCA) offers significant weight reduction compared to pure copper, making it ideal for applications where lighter materials are crucial, such as aerospace and telecommunications. CCA also provides a cost advantage by combining an aluminum core with a thin copper coating, reducing overall material expenses while maintaining adequate electrical conductivity. Pure copper, though heavier and costlier, delivers superior conductivity and durability, justifying its use in high-performance and long-lasting electrical systems.

Application Suitability: When to Use Each Material

Copper Clad Aluminum (CCA) is ideal for applications requiring lightweight and cost-effective wiring, such as in telecommunications and overhead power distribution, where conductivity and weight savings are balanced. Pure copper offers superior electrical conductivity, corrosion resistance, and durability, making it suitable for critical electrical systems, high-performance electronics, and building wiring where reliability is paramount. Choosing between CCA and pure copper depends on factors like budget constraints, environmental conditions, and the specific electrical load requirements of the project.

Longevity and Durability Considerations

Copper clad aluminum (CCA) cables offer a lightweight and cost-effective alternative to pure copper, but their longevity and durability are generally inferior due to aluminum's higher susceptibility to oxidation and mechanical fatigue. Pure copper provides superior conductivity and resistance to corrosion, resulting in longer lifespan and more reliable performance in demanding electrical and communication applications. For critical installations where durability and sustained conductivity are essential, pure copper remains the preferred choice despite its higher cost.

Environmental Impact and Recyclability

Copper clad aluminum (CCA) offers a lighter alternative to pure copper, reducing mining demand and associated environmental degradation, though its aluminum core complicates recycling processes compared to pure copper's highly efficient recyclability. Pure copper is favored for its superior recyclability, allowing materials to be reused repeatedly without loss of conductivity, minimizing the environmental footprint through decreased energy consumption in recycling. The combined materials in CCA require specialized separation techniques, potentially increasing recycling costs and limiting the circular economy benefits achievable with pure copper.

Choosing the Right Material for Your Project

Copper clad aluminum (CCA) offers a cost-effective alternative to pure copper by combining a lightweight aluminum core with a conductive copper outer layer, making it suitable for applications requiring reduced weight and lower expenses. Pure copper provides superior electrical conductivity, corrosion resistance, and durability, ideal for high-performance electrical wiring and grounding systems where long-term reliability is crucial. Selecting between CCA and pure copper depends on project requirements such as budget constraints, conductivity needs, mechanical strength, and environmental factors affecting longevity.

Copper Clad Aluminum vs Pure Copper Infographic

materialdif.com

materialdif.com