Copper foil is a thin, flexible material commonly used in electronics and crafting for its excellent conductivity and ease of shaping, while copper sheet is thicker and offers greater durability and structural strength for industrial and architectural applications. Copper foil provides superior surface contact and is ideal for applications requiring precise electrical performance, whereas copper sheet is preferred for projects demanding robustness and long-term wear resistance. Choosing between copper foil and copper sheet depends on the specific requirements of flexibility, conductivity, and mechanical strength in the intended application.

Table of Comparison

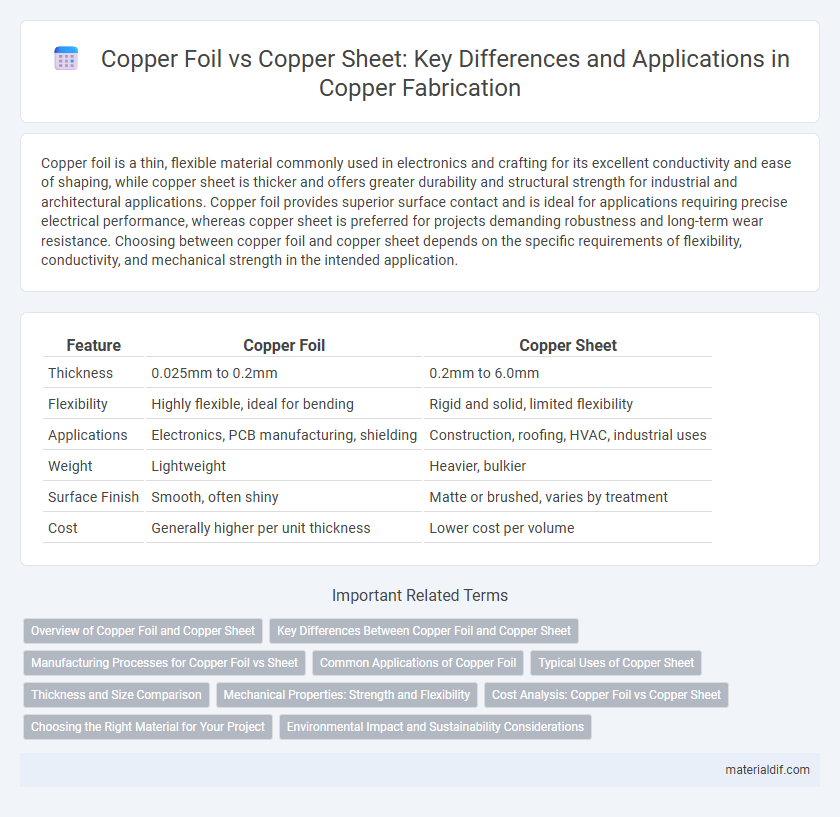

| Feature | Copper Foil | Copper Sheet |

|---|---|---|

| Thickness | 0.025mm to 0.2mm | 0.2mm to 6.0mm |

| Flexibility | Highly flexible, ideal for bending | Rigid and solid, limited flexibility |

| Applications | Electronics, PCB manufacturing, shielding | Construction, roofing, HVAC, industrial uses |

| Weight | Lightweight | Heavier, bulkier |

| Surface Finish | Smooth, often shiny | Matte or brushed, varies by treatment |

| Cost | Generally higher per unit thickness | Lower cost per volume |

Overview of Copper Foil and Copper Sheet

Copper foil is a thin layer of copper metal, typically less than 0.2 millimeters thick, known for its flexibility and excellent electrical conductivity, making it ideal for applications such as printed circuit boards, electromagnetic shielding, and flexible electronics. Copper sheets are thicker, rigid plates of copper used in construction, roofing, and industrial manufacturing, offering superior mechanical strength and durability compared to copper foil. The choice between copper foil and copper sheet depends on factors like thickness, flexibility, conductivity requirements, and the specific industrial application.

Key Differences Between Copper Foil and Copper Sheet

Copper foil features a thin, flexible structure with thicknesses typically ranging from 0.018 to 0.15 millimeters, making it ideal for applications requiring lightweight and moldable material such as in electronics and shielding. Copper sheets are thicker, generally starting at 0.2 millimeters and up, offering greater strength and durability, suitable for roofing, sculptures, and industrial uses. The key differences lie in thickness, flexibility, and application, with copper foil excelling in precision and electrical conductivity, while copper sheets provide structural support and sturdiness.

Manufacturing Processes for Copper Foil vs Sheet

Copper foil is produced through a continuous casting and rolling process that reduces thick copper slabs into ultra-thin, flexible sheets, ideal for fine electronics and flexible circuits. Copper sheets are manufactured via hot rolling followed by cold rolling, creating thicker, rigid plates suitable for structural applications and heavy-duty electrical components. The controlled cooling and annealing steps differ significantly, with foil emphasizing uniform thinness and sheet focusing on mechanical strength and durability.

Common Applications of Copper Foil

Copper foil is widely used in electronics for its excellent conductivity and flexibility, making it ideal for printed circuit boards (PCBs) and electromagnetic interference (EMI) shielding. It is also common in battery manufacturing, especially in lithium-ion batteries, where copper foil serves as an anode current collector. Additionally, copper foil finds applications in flexible electronics, heat sinks, and decorative arts due to its thin profile and malleability.

Typical Uses of Copper Sheet

Copper sheet is commonly used in electrical applications, roofing, and decorative arts due to its excellent conductivity, corrosion resistance, and malleability. Its thickness and rigidity make it ideal for manufacturing durable components like heat exchangers, architectural elements, and industrial machinery parts. Copper sheets are also preferred in plumbing and automotive industries for creating reliable, long-lasting fittings and gaskets.

Thickness and Size Comparison

Copper foil typically ranges from 0.012 mm to 0.2 mm in thickness, offering a thin, flexible option ideal for electronics and shielding applications, while copper sheets are much thicker, generally starting at 0.2 mm and extending beyond several millimeters, providing more rigidity and structural support. Copper foil is available in narrow widths, commonly up to 610 mm, suitable for precise, small-scale uses, whereas copper sheets come in larger sizes, often up to 1220 mm by 2440 mm, catering to industrial and architectural needs. The significant differences in thickness and size between copper foil and copper sheet determine their specific applications in manufacturing and construction.

Mechanical Properties: Strength and Flexibility

Copper foil exhibits superior flexibility due to its thin gauge, making it ideal for applications requiring bending or shaping without cracking. Copper sheets offer higher tensile strength and durability, suitable for structural uses where rigidity and mechanical support are essential. The choice between copper foil and sheet depends on the balance between required strength and flexibility for specific industrial or electrical applications.

Cost Analysis: Copper Foil vs Copper Sheet

Copper foil typically costs more per square meter than copper sheet due to its thinner gauge and specialized manufacturing process. Copper sheets offer a lower price point, making them more cost-effective for applications requiring thicker material and bulk usage. The cost difference is influenced by factors such as production complexity, material thickness, and intended industrial applications.

Choosing the Right Material for Your Project

Copper foil offers excellent electrical conductivity and flexibility, making it ideal for intricate electronic circuits and shielding applications. Copper sheets provide greater mechanical strength and durability, suited for structural uses and heat exchangers. Selecting the right copper material depends on the project's electrical requirements, strength needs, and form factor constraints.

Environmental Impact and Sustainability Considerations

Copper foil, thinner and more flexible than copper sheets, requires less raw material, reducing resource consumption and lowering its environmental footprint. Copper sheets, although thicker and more durable, often involve higher energy use in production and transportation due to their weight, contributing to increased emissions. Choosing copper foil supports sustainable practices through efficient material usage and potential for recycling in electronics and renewable energy applications.

Copper Foil vs Copper Sheet Infographic

materialdif.com

materialdif.com