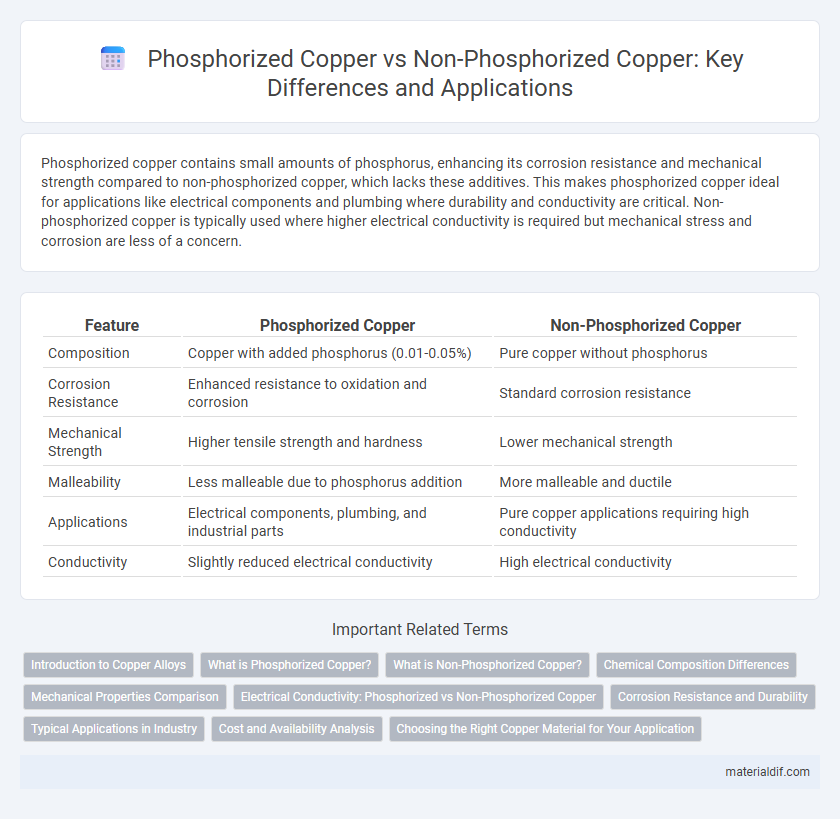

Phosphorized copper contains small amounts of phosphorus, enhancing its corrosion resistance and mechanical strength compared to non-phosphorized copper, which lacks these additives. This makes phosphorized copper ideal for applications like electrical components and plumbing where durability and conductivity are critical. Non-phosphorized copper is typically used where higher electrical conductivity is required but mechanical stress and corrosion are less of a concern.

Table of Comparison

| Feature | Phosphorized Copper | Non-Phosphorized Copper |

|---|---|---|

| Composition | Copper with added phosphorus (0.01-0.05%) | Pure copper without phosphorus |

| Corrosion Resistance | Enhanced resistance to oxidation and corrosion | Standard corrosion resistance |

| Mechanical Strength | Higher tensile strength and hardness | Lower mechanical strength |

| Malleability | Less malleable due to phosphorus addition | More malleable and ductile |

| Applications | Electrical components, plumbing, and industrial parts | Pure copper applications requiring high conductivity |

| Conductivity | Slightly reduced electrical conductivity | High electrical conductivity |

Introduction to Copper Alloys

Phosphorized copper contains a small percentage of phosphorus, enhancing its strength, wear resistance, and corrosion tolerance compared to non-phosphorized copper, which is softer and more ductile. The addition of phosphorus improves solderability and reduces oxidation in copper alloys, making phosphorized copper ideal for electrical connectors and marine applications. Non-phosphorized copper remains preferred for applications needing high electrical conductivity and excellent formability, such as electrical wiring and plumbing.

What is Phosphorized Copper?

Phosphorized copper is a type of copper alloy that contains a small percentage of phosphorus, typically ranging from 0.01% to 0.35%, which enhances its strength, hardness, and corrosion resistance. The addition of phosphorus improves the alloy's wear resistance and reduces the material's tendency to form copper oxide, making it ideal for electrical applications, plumbing, and marine environments. Non-phosphorized copper, in contrast, lacks this phosphorus content, resulting in higher ductility but lower resistance to wear and corrosion.

What is Non-Phosphorized Copper?

Non-phosphorized copper is a pure form of copper that does not contain added phosphorus, resulting in higher electrical and thermal conductivity compared to phosphorized variants. It is widely used in electrical wiring, plumbing, and heat exchangers where maximum conductivity and corrosion resistance are essential. Unlike phosphorized copper, it lacks the enhanced mechanical strength provided by phosphorus, making it more suitable for applications requiring excellent ductility and workability.

Chemical Composition Differences

Phosphorized copper contains a small percentage of phosphorus, typically between 0.01% to 0.35%, which enhances its strength, corrosion resistance, and wear properties. Non-phosphorized copper primarily consists of pure copper with minimal impurities, lacking the phosphorus element that alters the chemical structure and performance characteristics. The phosphorus in phosphorized copper forms copper phosphide during processing, improving its mechanical properties compared to non-phosphorized copper.

Mechanical Properties Comparison

Phosphorized copper exhibits enhanced mechanical properties, including higher tensile strength and improved hardness, due to the addition of phosphorus, which refines the grain structure and reduces brittleness. In contrast, non-phosphorized copper typically offers better electrical conductivity but lower mechanical strength and wear resistance. These differences make phosphorized copper preferable for applications requiring durability and resistance to fatigue, while non-phosphorized copper is favored in electrical and thermal conductivity-focused uses.

Electrical Conductivity: Phosphorized vs Non-Phosphorized Copper

Phosphorized copper contains a small percentage of phosphorus, which enhances its corrosion resistance and mechanical strength but slightly reduces its electrical conductivity compared to non-phosphorized copper. Non-phosphorized copper typically exhibits higher electrical conductivity, making it preferable for applications requiring optimal electrical performance. The conductivity of non-phosphorized copper generally ranges around 97% IACS (International Annealed Copper Standard), whereas phosphorized copper conductivity may drop to approximately 94-95% IACS due to phosphorus content.

Corrosion Resistance and Durability

Phosphorized copper contains a small percentage of phosphorus, which enhances its corrosion resistance by forming a protective oxide layer, making it ideal for plumbing and marine applications. Non-phosphorized copper lacks this phosphorus content, resulting in lower resistance to corrosive environments and reduced durability over time. The improved corrosion resistance of phosphorized copper extends the lifespan of components exposed to moisture and chemicals compared to non-phosphorized variants.

Typical Applications in Industry

Phosphorized copper, known for its enhanced hardness and corrosion resistance, is commonly used in electrical connectors, plumbing components, and heat exchangers where durability under stress is critical. Non-phosphorized copper, prized for its excellent electrical conductivity and ease of fabrication, finds typical applications in electrical wiring, roofing, and decorative arts. Industries select phosphorized copper for performance in harsh environments, while non-phosphorized copper is preferred for applications requiring superior electrical and thermal conductivity.

Cost and Availability Analysis

Phosphorized copper typically incurs higher production costs due to the addition of phosphorus, which enhances corrosion resistance and mechanical strength, increasing its market price compared to non-phosphorized copper. Availability of phosphorized copper is more limited because of specialized manufacturing processes, whereas non-phosphorized copper is widely available and commonly used in electrical and plumbing applications. The cost premium and moderate availability of phosphorized copper generally restrict its use to niche industries requiring superior durability and conductivity.

Choosing the Right Copper Material for Your Application

Phosphorized copper contains a small percentage of phosphorus, enhancing its corrosion resistance, strength, and solderability, making it ideal for plumbing, electrical, and automotive applications requiring durability and reliability. Non-phosphorized copper offers higher electrical conductivity and flexibility but is less resistant to wear and corrosion, suiting applications where maximum conductivity is critical without exposure to harsh environments. Selecting the right copper material depends on balancing the need for mechanical strength and corrosion resistance against requirements for electrical performance and formability in your specific application.

Phosphorized Copper vs Non-Phosphorized Copper Infographic

materialdif.com

materialdif.com