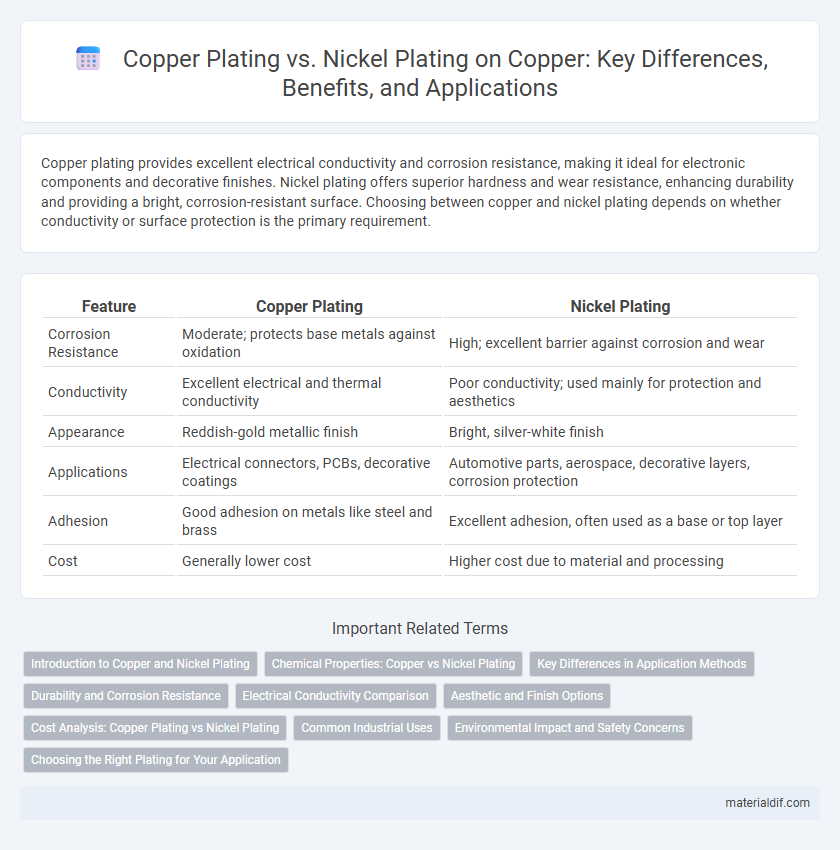

Copper plating provides excellent electrical conductivity and corrosion resistance, making it ideal for electronic components and decorative finishes. Nickel plating offers superior hardness and wear resistance, enhancing durability and providing a bright, corrosion-resistant surface. Choosing between copper and nickel plating depends on whether conductivity or surface protection is the primary requirement.

Table of Comparison

| Feature | Copper Plating | Nickel Plating |

|---|---|---|

| Corrosion Resistance | Moderate; protects base metals against oxidation | High; excellent barrier against corrosion and wear |

| Conductivity | Excellent electrical and thermal conductivity | Poor conductivity; used mainly for protection and aesthetics |

| Appearance | Reddish-gold metallic finish | Bright, silver-white finish |

| Applications | Electrical connectors, PCBs, decorative coatings | Automotive parts, aerospace, decorative layers, corrosion protection |

| Adhesion | Good adhesion on metals like steel and brass | Excellent adhesion, often used as a base or top layer |

| Cost | Generally lower cost | Higher cost due to material and processing |

Introduction to Copper and Nickel Plating

Copper plating offers excellent electrical conductivity and corrosion resistance, making it ideal for electronic components and decorative finishes. Nickel plating provides superior hardness and wear resistance, often used for protective and aesthetic purposes on metal surfaces. Both methods enhance the durability and appearance of substrates but serve distinct functional needs depending on the application requirements.

Chemical Properties: Copper vs Nickel Plating

Copper plating offers excellent electrical conductivity and superior thermal properties due to copper's high electron mobility, making it ideal for electronic components. Nickel plating provides enhanced corrosion resistance and hardness because of its chemically stable oxide layer, improving durability in harsh environments. The distinct chemical properties of copper and nickel significantly influence their suitability for applications requiring specific conductivity or protective qualities.

Key Differences in Application Methods

Copper plating involves electrodeposition where copper ions are reduced onto a substrate, often used for enhancing electrical conductivity and corrosion resistance. Nickel plating utilizes an electrochemical process to deposit a nickel layer, providing superior hardness and wear resistance compared to copper. Application methods differ significantly in bath composition, operating temperature, and current density, influencing the final coating's thickness, adhesion, and durability.

Durability and Corrosion Resistance

Copper plating offers excellent electrical conductivity and moderate corrosion resistance but tends to be softer and less durable than nickel plating. Nickel plating provides superior hardness and significantly enhanced corrosion resistance, making it ideal for harsh environments requiring long-lasting protection. The choice between copper and nickel plating depends on the need for conductivity versus durability and corrosion protection.

Electrical Conductivity Comparison

Copper plating offers superior electrical conductivity, typically around 5.8 x 10^7 S/m, making it ideal for applications requiring efficient current flow. Nickel plating, with a lower conductivity near 1.4 x 10^7 S/m, provides more corrosion resistance but compromises electrical performance. Engineers prioritize copper plating for electrical contacts and connectors to minimize energy loss and enhance signal transmission.

Aesthetic and Finish Options

Copper plating offers a rich, warm appearance with excellent conductivity and a natural reddish-gold finish, ideal for decorative applications requiring a vintage or rustic aesthetic. Nickel plating provides a harder, more durable surface with a bright, silver-white finish that resists tarnish and corrosion, making it suitable for modern, sleek designs. Both plating options support various finishes, including matte, satin, and high-gloss, allowing customization based on visual preference and functional requirements.

Cost Analysis: Copper Plating vs Nickel Plating

Copper plating offers a cost-effective solution with lower raw material expenses and simpler processing compared to nickel plating, which demands higher-quality alloys and more complex treatment. The durability and corrosion resistance of nickel plating often justify its increased cost in high-performance applications, despite the elevated initial investment. Evaluating total lifecycle costs highlights copper plating's economic advantage for decorative or electrical purposes, while nickel plating is preferred for applications requiring enhanced wear resistance and longevity.

Common Industrial Uses

Copper plating is widely used in electronics manufacturing for its excellent electrical conductivity and corrosion resistance, making it ideal for printed circuit boards and electrical connectors. Nickel plating offers superior hardness and wear resistance, commonly applied in automotive parts, aerospace components, and household hardware to enhance durability. Both plating methods improve surface properties but are selected based on specific industrial requirements such as conductivity for copper and protective coating for nickel.

Environmental Impact and Safety Concerns

Copper plating generates less toxic waste compared to nickel plating, which often involves hazardous chemicals like nickel sulfate and nickel chloride that pose significant environmental and health risks. Nickel plating can release carcinogenic compounds and heavy metals into the environment, leading to stricter disposal regulations and worker safety concerns. Copper plating, while still requiring proper handling, is generally considered safer for both ecosystems and human health due to lower toxicity and ease of waste management.

Choosing the Right Plating for Your Application

Copper plating offers superior electrical conductivity and excellent corrosion resistance, making it ideal for electronic components and decorative finishes. Nickel plating provides greater hardness and wear resistance, suited for mechanical parts exposed to friction or harsh environments. Selecting the right plating depends on balancing conductivity, durability, and environmental exposure specific to your application needs.

Copper Plating vs Nickel Plating Infographic

materialdif.com

materialdif.com