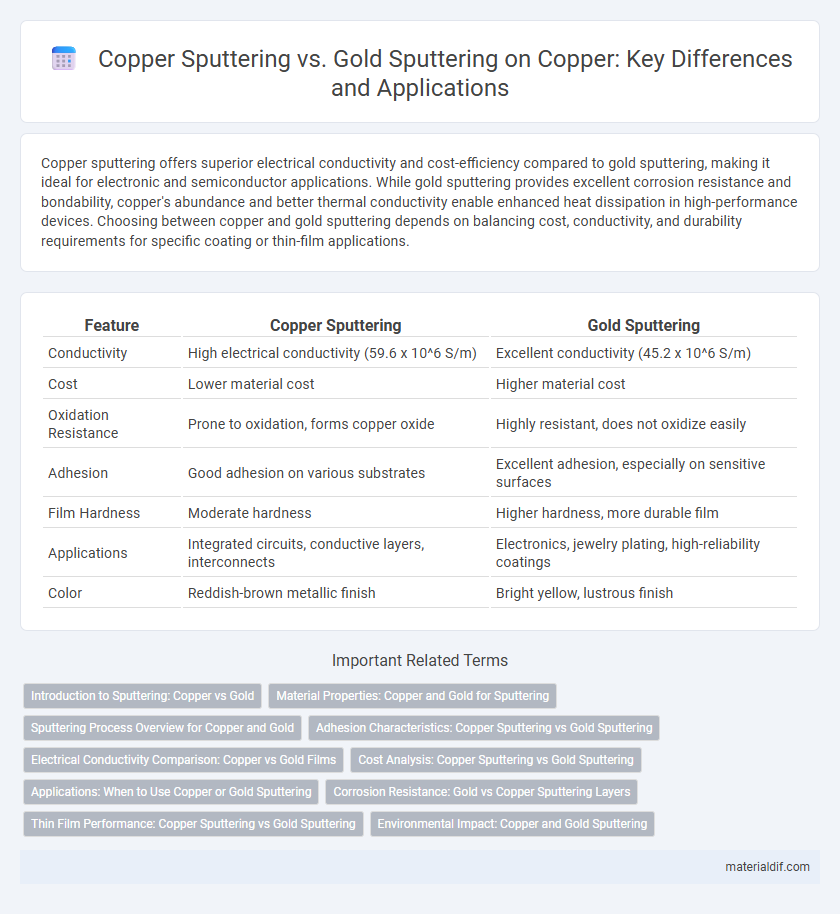

Copper sputtering offers superior electrical conductivity and cost-efficiency compared to gold sputtering, making it ideal for electronic and semiconductor applications. While gold sputtering provides excellent corrosion resistance and bondability, copper's abundance and better thermal conductivity enable enhanced heat dissipation in high-performance devices. Choosing between copper and gold sputtering depends on balancing cost, conductivity, and durability requirements for specific coating or thin-film applications.

Table of Comparison

| Feature | Copper Sputtering | Gold Sputtering |

|---|---|---|

| Conductivity | High electrical conductivity (59.6 x 10^6 S/m) | Excellent conductivity (45.2 x 10^6 S/m) |

| Cost | Lower material cost | Higher material cost |

| Oxidation Resistance | Prone to oxidation, forms copper oxide | Highly resistant, does not oxidize easily |

| Adhesion | Good adhesion on various substrates | Excellent adhesion, especially on sensitive surfaces |

| Film Hardness | Moderate hardness | Higher hardness, more durable film |

| Applications | Integrated circuits, conductive layers, interconnects | Electronics, jewelry plating, high-reliability coatings |

| Color | Reddish-brown metallic finish | Bright yellow, lustrous finish |

Introduction to Sputtering: Copper vs Gold

Sputtering is a physical vapor deposition process used to deposit thin films of materials like copper and gold onto substrates, crucial in electronics and semiconductor industries. Copper sputtering offers excellent electrical conductivity and cost-effectiveness, making it ideal for circuit applications, while gold sputtering provides superior corrosion resistance and stable electrical performance in harsh environments. The choice between copper and gold sputtering depends on application requirements such as conductivity, durability, and budget constraints.

Material Properties: Copper and Gold for Sputtering

Copper sputtering offers high electrical conductivity and excellent thermal performance, making it ideal for applications requiring efficient heat dissipation and electrical pathways. Gold sputtering provides superior corrosion resistance and excellent chemical stability, which is critical for devices exposed to harsh environments. While copper has a lower material cost and higher ductility, gold's inert nature ensures long-term reliability in sensitive electronic and optical components.

Sputtering Process Overview for Copper and Gold

Copper sputtering involves the ejection of copper atoms from a copper target under argon plasma conditions, enabling high conductivity and cost-effective thin film deposition for electronic applications. Gold sputtering, utilizing a similar plasma-based process, offers superior corrosion resistance and biocompatibility, ideal for specialized microelectronics and medical devices. Both processes rely on controlled ion bombardment to achieve uniform coatings, but copper's higher sputter yield enhances deposition efficiency compared to gold.

Adhesion Characteristics: Copper Sputtering vs Gold Sputtering

Copper sputtering offers superior adhesion characteristics on silicon substrates compared to gold sputtering, primarily due to its higher affinity for forming strong chemical bonds with oxide layers. Gold sputtering typically requires an adhesion layer, such as titanium or chromium, to enhance its bonding strength, as gold inherently exhibits poor adhesion to most substrates. The enhanced adhesion of copper sputtering improves the durability and reliability of thin films in microelectronic applications.

Electrical Conductivity Comparison: Copper vs Gold Films

Copper sputtering produces films with electrical conductivity of approximately 5.96 x 10^7 S/m, closely rivaling its bulk conductivity and surpassing many metals used in electronics. Gold sputtering yields films with conductivity around 4.1 x 10^7 S/m, offering excellent resistance to oxidation but lower conductivity than copper films. The superior electrical conductivity of copper films makes them highly suitable for applications requiring efficient current flow, while gold films are preferred for corrosion-resistant contacts despite slightly higher electrical resistance.

Cost Analysis: Copper Sputtering vs Gold Sputtering

Copper sputtering offers a significantly lower cost per unit compared to gold sputtering due to the abundant availability and lower market price of copper. Gold sputtering requires higher material costs and greater equipment maintenance expenses, increasing the overall process expenditure. Considering cost efficiency, copper sputtering is more economically viable for large-scale industrial applications.

Applications: When to Use Copper or Gold Sputtering

Copper sputtering is ideal for applications requiring excellent electrical conductivity and cost efficiency, such as printed circuit boards and flexible electronics. Gold sputtering is preferred for high-reliability applications demanding superior corrosion resistance and biocompatibility, including medical devices and aerospace components. Choosing between copper and gold sputtering depends on balancing conductivity, durability, and budget constraints tailored to the specific application.

Corrosion Resistance: Gold vs Copper Sputtering Layers

Gold sputtering layers exhibit superior corrosion resistance compared to copper sputtered coatings due to gold's inert chemical properties and resistance to oxidation. Copper sputtered layers tend to oxidize and corrode when exposed to moisture and atmospheric contaminants, which can degrade electrical conductivity and aesthetic quality. Selecting gold sputtering for applications requiring long-term reliability and environmental stability ensures enhanced durability and protection against corrosion.

Thin Film Performance: Copper Sputtering vs Gold Sputtering

Copper sputtering offers superior electrical conductivity and lower resistivity compared to gold sputtering, enhancing thin film performance in microelectronic applications. Copper films demonstrate better adhesion and higher thermal stability, which contributes to improved durability and reliability of thin films under thermal stress. Conversely, gold sputtering provides excellent corrosion resistance and stable chemical properties, but its higher cost and relatively lower mechanical strength limit its use in high-performance thin film applications.

Environmental Impact: Copper and Gold Sputtering

Copper sputtering releases fewer toxic byproducts compared to gold sputtering, resulting in a lower environmental footprint during the deposition process. Copper's higher abundance and recyclability contribute to reduced mining and resource depletion impacts relative to gold. In contrast, gold sputtering involves more energy-intensive extraction and refining, leading to greater carbon emissions and hazardous waste generation.

Copper Sputtering vs Gold Sputtering Infographic

materialdif.com

materialdif.com