Copper ingots are refined, cast blocks of copper with a uniform composition, ideal for long-term storage and transport before further processing. Copper billets are semi-finished products, often cylindrical, used directly in forging and rolling to produce detailed copper components. Choosing between copper ingots and billets depends on the manufacturing stage and specific application requirements in metalworking.

Table of Comparison

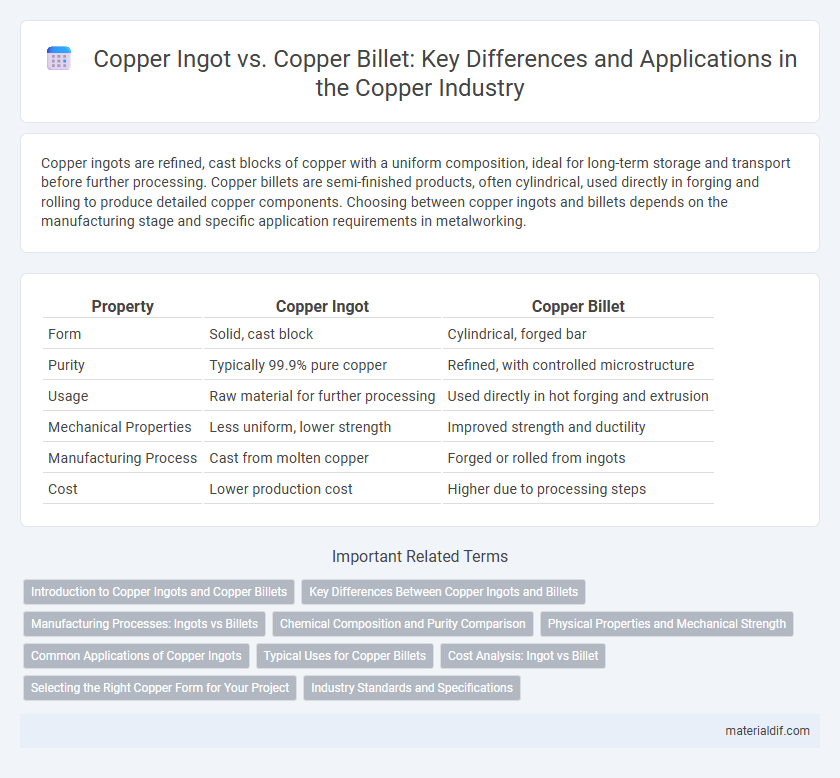

| Property | Copper Ingot | Copper Billet |

|---|---|---|

| Form | Solid, cast block | Cylindrical, forged bar |

| Purity | Typically 99.9% pure copper | Refined, with controlled microstructure |

| Usage | Raw material for further processing | Used directly in hot forging and extrusion |

| Mechanical Properties | Less uniform, lower strength | Improved strength and ductility |

| Manufacturing Process | Cast from molten copper | Forged or rolled from ingots |

| Cost | Lower production cost | Higher due to processing steps |

Introduction to Copper Ingots and Copper Billets

Copper ingots are solid blocks of pure copper produced through the casting process, designed for ease of storage, transport, and melting. Copper billets are semi-finished copper products shaped into smaller, rectangular blocks, primarily used as raw material for rolling, extrusion, and forging in industrial manufacturing. Both forms are essential in copper processing, with ingots serving as initial cast products and billets providing a more refined shape for advanced fabrication.

Key Differences Between Copper Ingots and Billets

Copper ingots are large, rectangular blocks produced through casting molten copper into molds, primarily used for storage and transportation due to their solid form and ease of melting. Copper billets, on the other hand, are smaller, cylindrical or square-shaped semi-finished products created by hot or cold working processes, serving as raw material for further manufacturing like extrusion or rolling. Key differences include shape, size, manufacturing method, and direct applicability for subsequent industrial processes, with billets offering better mechanical properties for shaping.

Manufacturing Processes: Ingots vs Billets

Copper ingots are produced by casting molten copper into molds, allowing the metal to solidify into large, easily transportable blocks that require further processing. Copper billets undergo additional extrusion or continuous casting processes, resulting in smaller, uniform shapes that are closer to final product specifications and ideal for rolling or forging. The manufacturing differences impact the metal's microstructure, mechanical properties, and suitability for various industrial applications.

Chemical Composition and Purity Comparison

Copper ingots typically exhibit a high purity level of around 99.9% copper, with minimal impurities such as oxygen, sulfur, and iron, making them ideal for high-quality electrical and industrial applications. Copper billets, although still predominantly pure copper, may contain slightly higher levels of minor alloys and trace elements introduced during secondary processing, which can affect their mechanical properties and suitability for extrusion or rolling. The chemical composition difference between copper ingots and billets primarily influences their conductivity, strength, and malleability, with ingots preferred for applications requiring superior purity and billets favored for manufacturing processes requiring specific mechanical characteristics.

Physical Properties and Mechanical Strength

Copper ingots exhibit a coarser grain structure with relatively lower mechanical strength, making them suitable for melting and casting processes. In contrast, copper billets have a finer, more uniform grain structure due to controlled solidification and forging, resulting in enhanced tensile strength, hardness, and improved ductility. The denser microstructure in copper billets makes them ideal for extrusion and rolling applications requiring superior mechanical performance.

Common Applications of Copper Ingots

Copper ingots are widely used in electrical and plumbing industries due to their high conductivity and corrosion resistance, making them ideal for manufacturing wires, pipes, and electrical components. These ingots serve as a primary raw material for casting and forging processes in the production of industrial machinery and automotive parts. Their standardized shape and purity facilitate efficient melting and alloying in metal foundries and fabrication workshops.

Typical Uses for Copper Billets

Copper billets are predominantly used as raw materials for manufacturing high-quality copper wire rods, tubes, and specialized connectors due to their uniform grain structure and superior mechanical properties. They are essential in industries such as electrical engineering, plumbing, and automotive manufacturing, where precise metal forming and machining are required. Copper billets offer enhanced durability and conductivity, making them ideal for producing components that demand consistent performance and reliability.

Cost Analysis: Ingot vs Billet

Copper ingots generally have a lower production cost compared to copper billets due to simpler casting processes and less intensive machining requirements. Billets, requiring further hot or cold working to achieve desired mechanical properties and shapes, incur higher fabrication and energy costs. When considering bulk purchasing, ingots offer cost advantages for melting and alloying, while billets are more expensive but provide better uniformity and strength for precision manufacturing.

Selecting the Right Copper Form for Your Project

Copper ingots offer uniform shape and purity ideal for casting and large-scale manufacturing, while copper billets provide enhanced mechanical strength suitable for forging and extrusion processes. Understanding the specific requirements of your project, such as dimensional precision and thermal conductivity, will guide you in choosing between ingots and billets. Selecting the appropriate copper form optimizes material performance, reduces waste, and ensures cost-effective production outcomes.

Industry Standards and Specifications

Copper ingots and copper billets are distinguished by their specific industry standards and specifications that cater to different manufacturing processes; copper ingots typically conform to ASTM B170 for refined copper, ensuring high purity and uniformity for remelting and refining purposes. Copper billets follow ASTM B221 or equivalent standards, emphasizing precise dimensional tolerances and surface quality to facilitate extrusion and rolling operations in the metal fabrication industry. Stringent adherence to these specifications guarantees optimal performance and consistency in electrical, construction, and industrial applications.

Copper Ingot vs Copper Billet Infographic

materialdif.com

materialdif.com