Seamless copper tubes offer superior strength and corrosion resistance due to the absence of welded joints, making them ideal for high-pressure applications. Welded copper tubes are more cost-effective and easier to produce, but the weld seam can become a potential weak point under stress or extreme conditions. Choosing between seamless and welded copper tubes depends on specific use cases, balancing factors like durability, cost, and application requirements.

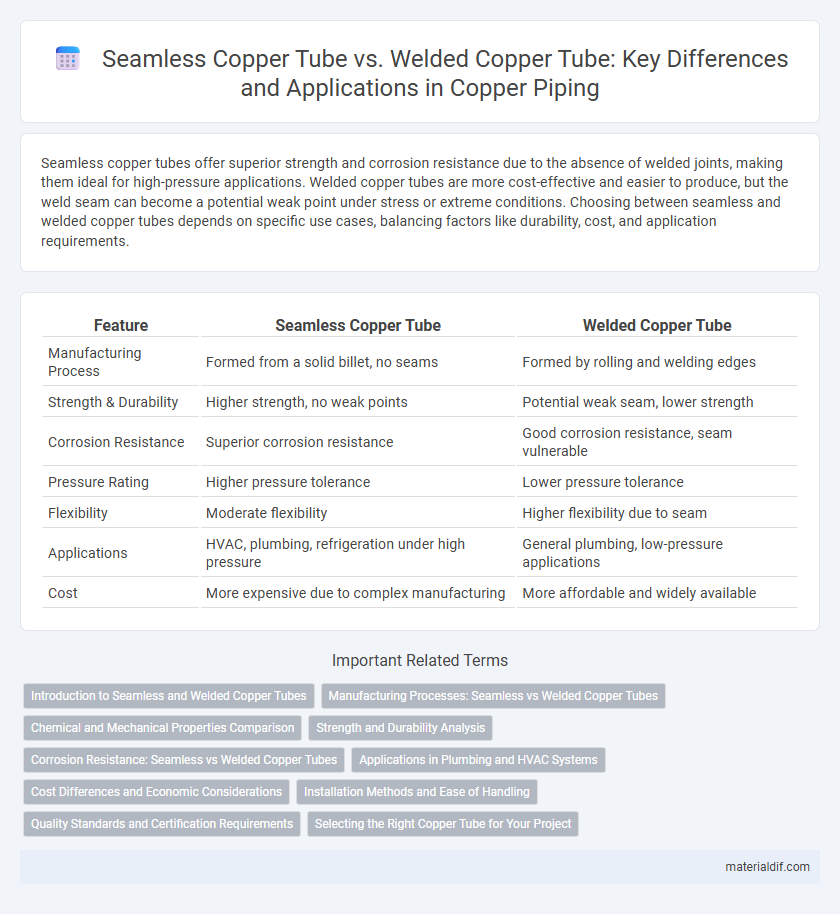

Table of Comparison

| Feature | Seamless Copper Tube | Welded Copper Tube |

|---|---|---|

| Manufacturing Process | Formed from a solid billet, no seams | Formed by rolling and welding edges |

| Strength & Durability | Higher strength, no weak points | Potential weak seam, lower strength |

| Corrosion Resistance | Superior corrosion resistance | Good corrosion resistance, seam vulnerable |

| Pressure Rating | Higher pressure tolerance | Lower pressure tolerance |

| Flexibility | Moderate flexibility | Higher flexibility due to seam |

| Applications | HVAC, plumbing, refrigeration under high pressure | General plumbing, low-pressure applications |

| Cost | More expensive due to complex manufacturing | More affordable and widely available |

Introduction to Seamless and Welded Copper Tubes

Seamless copper tubes are produced by extruding a solid copper billet, resulting in a tube with no joints or seams, which provides superior strength and resistance to high pressure and corrosion. Welded copper tubes are manufactured by shaping copper sheets or strips into a tube and welding the seam, offering cost efficiency and ease of production for applications with lower pressure requirements. Both types of copper tubes are widely used in plumbing, HVAC systems, and industrial applications, with the choice depending on specific performance and budget criteria.

Manufacturing Processes: Seamless vs Welded Copper Tubes

Seamless copper tubes are created through a hot extrusion process where a solid billet is heated and forced through a die to form a tube without any joints, ensuring uniform strength and superior corrosion resistance. Welded copper tubes, on the other hand, are manufactured by rolling copper strip or plate and welding the edges together, typically using high-frequency induction welding, which can introduce a weld seam prone to potential weaknesses under pressure. The seamless manufacturing process results in tubes ideal for high-pressure applications and superior mechanical properties, whereas welded tubes offer cost efficiency and flexibility for systems with lower pressure requirements.

Chemical and Mechanical Properties Comparison

Seamless copper tubes exhibit superior chemical uniformity and corrosion resistance due to their homogeneous structure, making them ideal for high-pressure applications where purity is critical. Welded copper tubes may contain slight metallurgical variations along the weld seam, potentially affecting mechanical strength and susceptibility to stress corrosion cracking under extreme conditions. In terms of mechanical properties, seamless tubes generally provide higher tensile strength and better flexibility, whereas welded tubes offer cost-effective performance with adequate durability for less demanding environments.

Strength and Durability Analysis

Seamless copper tubes exhibit superior strength and durability compared to welded copper tubes due to their uniform structure without seams, which minimizes the risk of leaks and weaknesses under high pressure. Welded copper tubes, while more cost-effective, may have inherent vulnerabilities along the welded joints that reduce their ability to withstand extreme stress and corrosive environments. For applications demanding the highest reliability, such as HVAC systems and industrial piping, seamless copper tubes provide enhanced performance and longer service life.

Corrosion Resistance: Seamless vs Welded Copper Tubes

Seamless copper tubes exhibit superior corrosion resistance compared to welded copper tubes due to the absence of weld seams, which are potential weak points for corrosion initiation. The uniform metallurgy of seamless tubes minimizes exposure to contaminants and stress concentrations, enhancing durability in harsh environments. Welded copper tubes may develop galvanic corrosion at the weld joints if not properly treated, reducing their lifespan in corrosive applications.

Applications in Plumbing and HVAC Systems

Seamless copper tubes are preferred in plumbing and HVAC systems for their superior strength, corrosion resistance, and ability to withstand high pressure, making them ideal for hot water and refrigerant lines. Welded copper tubes offer cost-effectiveness and are commonly used in residential plumbing for water supply and drainage systems where pressure requirements are moderate. Both types ensure reliable performance, but seamless tubes are favored in critical applications demanding durability and enhanced thermal conductivity.

Cost Differences and Economic Considerations

Seamless copper tubes generally incur higher manufacturing costs due to their complex extrusion process, resulting in greater market prices compared to welded copper tubes. Welded copper tubes offer cost advantages because they are produced by rolling and welding copper strips, which is less material-intensive and more economical for large-scale production. Economically, choosing welded tubes can reduce project expenses in non-critical applications, while seamless tubes provide long-term benefits in high-pressure or corrosion-sensitive environments despite their premium cost.

Installation Methods and Ease of Handling

Seamless copper tubes offer superior ease of handling due to their uniform thickness and absence of weld seams, which reduces the risk of leaks during installation. Welded copper tubes, while generally more affordable, require careful inspection of weld joints to ensure integrity, making their installation more labor-intensive. Both types benefit from copper's natural corrosion resistance, but seamless tubes typically enable faster and more reliable installation in critical plumbing and HVAC applications.

Quality Standards and Certification Requirements

Seamless copper tube is manufactured without joints, ensuring uniform strength and superior resistance to high pressure and corrosion, meeting stringent ASTM B75 and EN 12735 quality standards. Welded copper tube, produced by rolling and welding copper strips, often complies with ASTM B280 and EN 1057 standards, with certifications focusing on weld integrity and dimensional accuracy. Both types must adhere to ISO 9001 quality management systems, but seamless tubes typically undergo more rigorous testing for applications demanding higher durability and reliability.

Selecting the Right Copper Tube for Your Project

Seamless copper tubes offer superior strength and corrosion resistance, making them ideal for high-pressure applications such as refrigeration and plumbing systems. Welded copper tubes are more cost-effective and suitable for low-pressure uses or where dimensional precision is less critical, like in HVAC installations. Selecting the right copper tube depends on project requirements, including pressure ratings, durability needs, and budget constraints.

Seamless Copper Tube vs Welded Copper Tube Infographic

materialdif.com

materialdif.com