Hard-drawn copper features enhanced tensile strength and rigidity due to strain hardening during its manufacturing, making it ideal for applications requiring durability and resistance to deformation. Soft-annealed copper undergoes heat treatment that restores its ductility and electrical conductivity, allowing for easier bending and forming in electrical wiring and plumbing. Choosing between hard-drawn and soft-annealed copper depends on the balance needed between mechanical strength and malleability in specific industrial or construction applications.

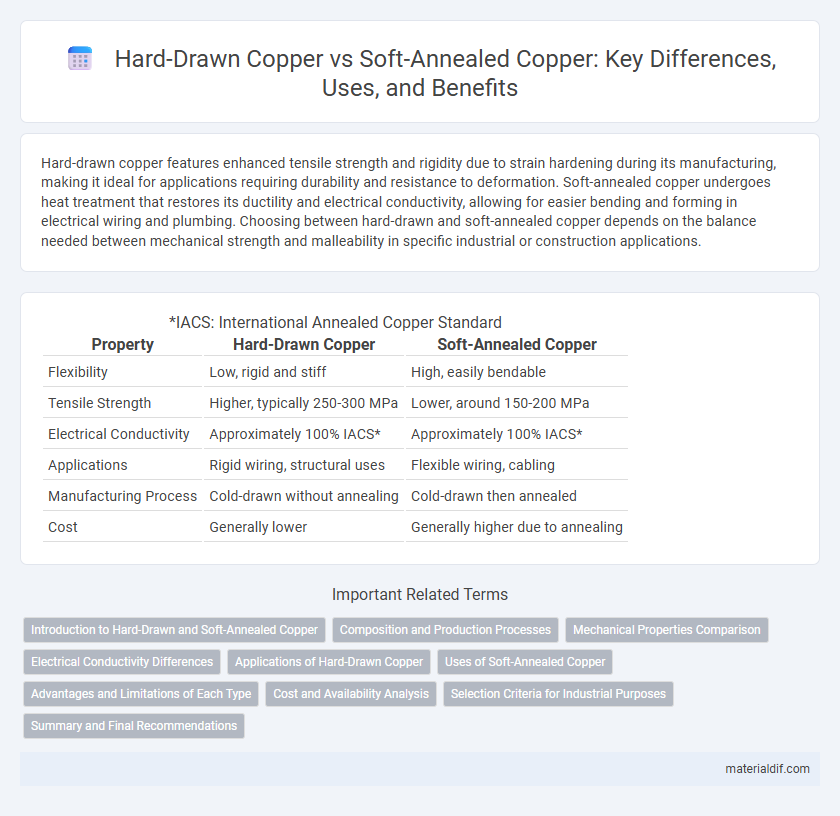

Table of Comparison

| Property | Hard-Drawn Copper | Soft-Annealed Copper |

|---|---|---|

| Flexibility | Low, rigid and stiff | High, easily bendable |

| Tensile Strength | Higher, typically 250-300 MPa | Lower, around 150-200 MPa |

| Electrical Conductivity | Approximately 100% IACS* | Approximately 100% IACS* |

| Applications | Rigid wiring, structural uses | Flexible wiring, cabling |

| Manufacturing Process | Cold-drawn without annealing | Cold-drawn then annealed |

| Cost | Generally lower | Generally higher due to annealing |

Introduction to Hard-Drawn and Soft-Annealed Copper

Hard-drawn copper is produced by cold working, which increases its tensile strength and hardness while reducing ductility, making it ideal for electrical wiring requiring mechanical durability. Soft-annealed copper undergoes a heat treatment process that restores its ductility and softness, enhancing flexibility and ease of bending for applications like plumbing and intricate electrical components. Both types balance conductivity and mechanical properties to suit specific industrial needs.

Composition and Production Processes

Hard-drawn copper is produced by cold working, which increases its tensile strength and hardness through strain hardening while maintaining its composition of approximately 99.9% pure copper with trace elements like oxygen and phosphorus. Soft-annealed copper undergoes a heat treatment process where the metal is heated to a specific temperature and slowly cooled, restoring its ductility by recrystallizing the grain structure without altering the chemical composition. Both types retain high conductivity but differ significantly in mechanical properties due to the contrasting production processes applied to the same basic copper alloy.

Mechanical Properties Comparison

Hard-drawn copper exhibits higher tensile strength and greater hardness compared to soft-annealed copper, making it suitable for applications requiring structural rigidity. Soft-annealed copper offers superior ductility and electrical conductivity due to its softer, more pliable microstructure. The mechanical property differences stem from their distinct manufacturing processes, where hard-drawing induces strain hardening and annealing reverses these effects for enhanced flexibility.

Electrical Conductivity Differences

Hard-drawn copper exhibits lower electrical conductivity compared to soft-annealed copper due to its higher tensile strength and reduced ductility from strain hardening. Soft-annealed copper undergoes heat treatment that restores its crystal structure, resulting in optimal electrical conductivity close to 100% IACS (International Annealed Copper Standard). Industries requiring maximum electrical efficiency, such as power transmission and electronics, typically prefer soft-annealed copper for its superior conductivity over hard-drawn variants.

Applications of Hard-Drawn Copper

Hard-drawn copper is used extensively in plumbing, electrical wiring, and HVAC systems due to its increased tensile strength and rigidity compared to soft-annealed copper. It is ideal for applications requiring strong, durable tubing and wiring that can withstand mechanical stress and maintain shape without kinking. Industries such as construction and manufacturing rely on hard-drawn copper for its superior resistance to deformation and enhanced conductivity under demanding conditions.

Uses of Soft-Annealed Copper

Soft-annealed copper is widely used in electrical wiring, plumbing, and HVAC systems due to its excellent ductility and ease of bending. Its enhanced malleability allows it to be shaped into intricate forms without cracking, making it ideal for manufacturing coils, connectors, and tubing. This copper type is preferred in applications requiring frequent deformation or fabrication, where flexibility and conductivity are priorities.

Advantages and Limitations of Each Type

Hard-drawn copper offers superior strength and durability, making it ideal for structural applications and electrical wiring that requires rigidity and resistance to deformation. Soft-annealed copper provides excellent flexibility and enhanced conductivity, suitable for tasks requiring easy bending and high electrical performance but lacks the mechanical strength of hard-drawn copper. While hard-drawn copper is limited by reduced malleability and higher brittleness, soft-annealed copper is more prone to damage under mechanical stress but excels in thermal and electrical efficiency.

Cost and Availability Analysis

Hard-drawn copper typically costs more than soft-annealed copper due to the additional manufacturing processes that enhance its strength and durability, making it suitable for structural applications. Soft-annealed copper, being more readily available and easier to work with, tends to have lower market prices and is preferred for electrical wiring and plumbing where flexibility is crucial. The availability of these copper types varies regionally, with hard-drawn copper often sourced from specialized suppliers, while soft-annealed copper benefits from broader distribution networks and higher production volumes.

Selection Criteria for Industrial Purposes

Hard-drawn copper offers superior tensile strength and durability, making it ideal for heavy-duty industrial applications where mechanical stress resistance is critical. Soft-annealed copper provides enhanced ductility and electrical conductivity, suitable for processes requiring frequent bending or complex shaping. Selection depends on the balance between mechanical strength and flexibility needed for specific industrial uses, such as electrical wiring or plumbing systems.

Summary and Final Recommendations

Hard-drawn copper features increased tensile strength and improved rigidity due to strain hardening, making it ideal for applications requiring structural stability and durability, such as electrical wiring in harsh environments. Soft-annealed copper offers superior flexibility and enhanced electrical conductivity, suitable for intricate wiring and components needing easy bending and shaping. Selecting between hard-drawn and soft-annealed copper depends on the balance between mechanical strength and electrical performance demanded by the specific application.

Hard-Drawn Copper vs Soft-Annealed Copper Infographic

materialdif.com

materialdif.com