Cupronickel, an alloy composed primarily of copper and nickel, offers superior corrosion resistance and durability compared to pure copper, making it ideal for marine environments and coinage. Pure copper provides excellent electrical and thermal conductivity but is softer and more prone to oxidation and wear. The choice between cupronickel and pure copper depends on the application requirements for strength, conductivity, and resistance to environmental factors.

Table of Comparison

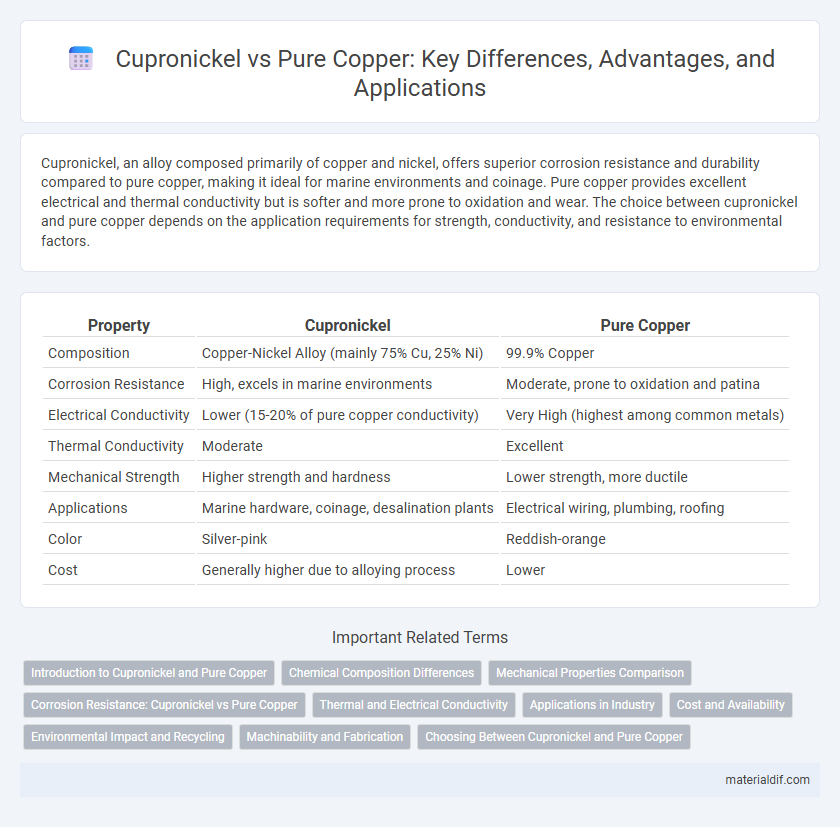

| Property | Cupronickel | Pure Copper |

|---|---|---|

| Composition | Copper-Nickel Alloy (mainly 75% Cu, 25% Ni) | 99.9% Copper |

| Corrosion Resistance | High, excels in marine environments | Moderate, prone to oxidation and patina |

| Electrical Conductivity | Lower (15-20% of pure copper conductivity) | Very High (highest among common metals) |

| Thermal Conductivity | Moderate | Excellent |

| Mechanical Strength | Higher strength and hardness | Lower strength, more ductile |

| Applications | Marine hardware, coinage, desalination plants | Electrical wiring, plumbing, roofing |

| Color | Silver-pink | Reddish-orange |

| Cost | Generally higher due to alloying process | Lower |

Introduction to Cupronickel and Pure Copper

Cupronickel is an alloy consisting primarily of copper and nickel, known for its excellent corrosion resistance, especially in marine environments, and strong antimicrobial properties. Pure copper, valued for its outstanding electrical and thermal conductivity, is widely used in electrical wiring and plumbing but is softer and more prone to oxidation compared to cupronickel. The combination of copper and nickel in cupronickel enhances durability and resistance to biofouling, making it ideal for seawater applications where pure copper would degrade more quickly.

Chemical Composition Differences

Cupronickel is an alloy primarily composed of copper and nickel, usually containing 60-90% copper and 10-40% nickel, with traces of iron and manganese enhancing corrosion resistance. Pure copper consists of 99.9% copper, with minimal impurities, which gives it superior electrical and thermal conductivity but lower hardness compared to cupronickel. The chemical composition difference significantly influences their mechanical properties and suitability for applications requiring corrosion resistance or electrical performance.

Mechanical Properties Comparison

Cupronickel alloys exhibit superior tensile strength and corrosion resistance compared to pure copper, making them ideal for marine and industrial applications where durability is critical. Pure copper offers excellent electrical and thermal conductivity but has lower hardness and wear resistance, limiting its use in high-stress environments. The mechanical properties of cupronickel, such as enhanced yield strength and elongation, provide improved performance over pure copper in structural and load-bearing applications.

Corrosion Resistance: Cupronickel vs Pure Copper

Cupronickel exhibits superior corrosion resistance compared to pure copper due to the presence of nickel, which enhances its ability to withstand seawater and other harsh environments. While pure copper is prone to oxidation and develops a green patina over time, cupronickel forms a stable, protective oxide layer that prevents further corrosion. This makes cupronickel the preferred choice for marine applications and heat exchangers where durability against corrosive agents is critical.

Thermal and Electrical Conductivity

Cupronickel exhibits significantly lower thermal and electrical conductivity compared to pure copper due to the alloying of nickel, which disrupts electron flow and heat transfer. Pure copper has an electrical conductivity of approximately 59.6 x 10^6 S/m and a thermal conductivity of about 401 W/m*K, making it one of the best conductors available. Cupronickel's electrical conductivity typically ranges from 2 to 15 x 10^6 S/m, and its thermal conductivity is around 29 to 45 W/m*K, suitable for applications requiring corrosion resistance rather than high conductivity.

Applications in Industry

Cupronickel, an alloy of copper and nickel, offers superior resistance to corrosion and biofouling, making it ideal for marine applications, desalination plants, and coinage. Pure copper is favored in electrical wiring and electronics due to its excellent electrical conductivity and thermal properties. While cupronickel excels in harsh environments, pure copper remains the industry standard for electrical and heat transfer applications.

Cost and Availability

Cupronickel typically costs more than pure copper due to the added nickel content and alloying process, impacting material expenses in industrial applications. Pure copper is generally more widely available and benefits from higher global mining production, making it a cost-effective choice for projects prioritizing material accessibility. The price fluctuations of both materials are influenced by global metal market demand, but nickel scarcity can lead to higher and more volatile costs for cupronickel alloys.

Environmental Impact and Recycling

Cupronickel, an alloy of copper and nickel, offers enhanced corrosion resistance compared to pure copper, reducing material degradation and waste in marine and industrial applications. Both materials are highly recyclable, but pure copper has a higher recycling rate and lower environmental impact due to its greater abundance and simpler processing requirements. The energy consumption for recycling cupronickel is slightly higher because separating the metals requires additional refining steps, contributing to a marginally larger carbon footprint.

Machinability and Fabrication

Cupronickel offers superior machinability compared to pure copper, thanks to its alloy composition that reduces work hardening and enhances tool life during fabrication. Pure copper, while highly ductile and conductive, can be more challenging to machine due to its softness and tendency to stick to cutting tools. The balanced strength and corrosion resistance of cupronickel make it more suitable for complex manufacturing processes requiring precise machining and forming.

Choosing Between Cupronickel and Pure Copper

Cupronickel offers superior corrosion resistance and durability compared to pure copper, making it ideal for marine and industrial applications where exposure to harsh environments is frequent. Pure copper provides excellent electrical and thermal conductivity, preferred in electrical wiring and heat exchanger components where efficiency is critical. Selecting between cupronickel and pure copper depends on balancing the need for corrosion resistance against the requirement for high conductivity in the intended application.

Cupronickel vs Pure Copper Infographic

materialdif.com

materialdif.com