Copper offers superior durability and thermal conductivity compared to PVC, making it ideal for plumbing and electrical applications requiring long-lasting, heat-resistant materials. Unlike PVC, which can degrade under high temperatures and exposes users to potential chemical leaching, copper remains stable and safe over time. Copper's natural antimicrobial properties further enhance its suitability for water supply systems, ensuring cleaner and safer water delivery.

Table of Comparison

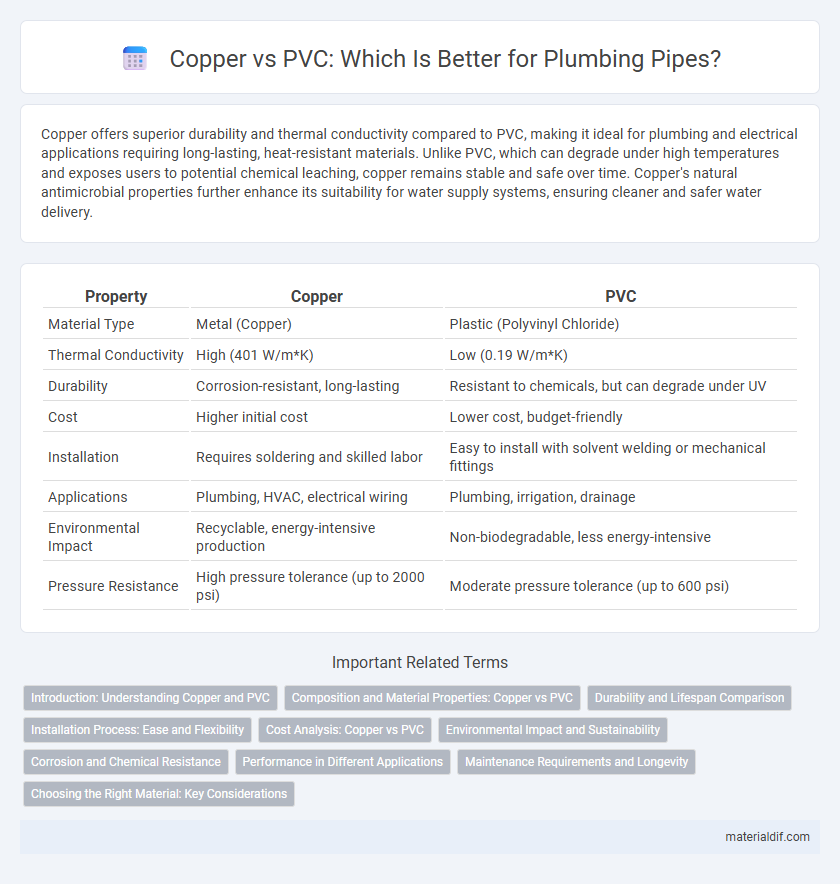

| Property | Copper | PVC |

|---|---|---|

| Material Type | Metal (Copper) | Plastic (Polyvinyl Chloride) |

| Thermal Conductivity | High (401 W/m*K) | Low (0.19 W/m*K) |

| Durability | Corrosion-resistant, long-lasting | Resistant to chemicals, but can degrade under UV |

| Cost | Higher initial cost | Lower cost, budget-friendly |

| Installation | Requires soldering and skilled labor | Easy to install with solvent welding or mechanical fittings |

| Applications | Plumbing, HVAC, electrical wiring | Plumbing, irrigation, drainage |

| Environmental Impact | Recyclable, energy-intensive production | Non-biodegradable, less energy-intensive |

| Pressure Resistance | High pressure tolerance (up to 2000 psi) | Moderate pressure tolerance (up to 600 psi) |

Introduction: Understanding Copper and PVC

Copper offers excellent thermal conductivity and natural antimicrobial properties, making it a preferred choice for plumbing and electrical applications. PVC, a lightweight and cost-effective plastic, provides superior corrosion resistance and ease of installation but lacks the durability and heat tolerance of copper. Both materials serve distinct roles in construction and infrastructure, with copper excelling in longevity and performance under high temperature, while PVC is valued for its affordability and chemical resistance.

Composition and Material Properties: Copper vs PVC

Copper is a metallic element with excellent thermal and electrical conductivity, known for its durability, corrosion resistance, and antimicrobial properties. PVC (polyvinyl chloride) is a synthetic plastic polymer composed of carbon, hydrogen, and chlorine atoms, valued for its lightweight, chemical resistance, and insulation capabilities. Copper's inherent strength and ability to withstand high temperatures contrast with PVC's flexibility and resistance to chemical degradation, making each material suited for different applications based on their composition and material properties.

Durability and Lifespan Comparison

Copper piping offers superior durability compared to PVC, with a lifespan often exceeding 50 years due to its resistance to corrosion, heat, and UV exposure. PVC pipes, while resistant to chemical corrosion, typically last around 25-40 years and can become brittle when exposed to prolonged sunlight or extreme temperatures. The inherent strength and longevity of copper make it a preferred choice for long-term plumbing solutions in harsh environments.

Installation Process: Ease and Flexibility

Copper pipes offer superior durability and corrosion resistance, yet their installation requires soldering and specialized tools, which can be time-consuming and less flexible. PVC pipes are lightweight and easier to cut and join with solvent cement, allowing for quicker installation and greater adaptability in tight spaces. The choice depends on project requirements, with copper favored for longevity and PVC for ease and speed of installation.

Cost Analysis: Copper vs PVC

Copper piping typically incurs higher initial costs compared to PVC due to raw material expenses and more labor-intensive installation processes. PVC offers a cost-effective alternative with lower material prices and quicker installation times, reducing overall project expenses. Long-term maintenance and durability factors should be considered, as copper's resistance to corrosion can result in lower lifetime costs despite its higher upfront price.

Environmental Impact and Sustainability

Copper is a highly sustainable material due to its 100% recyclability and long lifespan, significantly reducing environmental waste compared to PVC. PVC production involves toxic chemicals like chlorine and releases harmful dioxins during manufacturing and incineration, posing greater ecological risks. Copper's natural antimicrobial properties and energy efficiency in applications contribute further to its environmentally friendly profile over PVC.

Corrosion and Chemical Resistance

Copper exhibits superior corrosion resistance compared to PVC, particularly in environments with fluctuating temperatures and exposure to UV radiation. While PVC maintains excellent chemical resistance to acids and alkalis, copper withstands a broader range of corrosive conditions, including microbial-induced corrosion in water systems. The durability of copper in resisting oxidation and chemical degradation makes it a preferred choice for plumbing and industrial applications where long-term reliability is critical.

Performance in Different Applications

Copper exhibits superior thermal conductivity and corrosion resistance compared to PVC, making it ideal for plumbing systems that require durability and heat tolerance. PVC, while cost-effective and lightweight, lacks the strength and temperature resistance needed for high-pressure or high-temperature applications. In electrical wiring, copper's excellent conductivity ensures efficient energy transfer, whereas PVC serves mainly as insulation rather than a conductive material.

Maintenance Requirements and Longevity

Copper pipes offer superior longevity, often lasting over 50 years with minimal maintenance due to their corrosion resistance and durability. PVC pipes require less initial upkeep but are more prone to damage from UV exposure and physical stress, potentially reducing their lifespan to around 25-40 years. Maintenance of copper involves occasional inspections for corrosion or leaks, while PVC pipes may need more frequent replacements and protection against environmental factors.

Choosing the Right Material: Key Considerations

Copper offers superior durability, corrosion resistance, and thermal conductivity compared to PVC, making it ideal for plumbing and heating systems where longevity and heat transfer efficiency are critical. PVC is lightweight, cost-effective, and resistant to chemicals, suitable for drain, waste, and vent applications but less effective for high-temperature or pressure environments. Selecting the right material depends on factors such as budget, environmental exposure, installation complexity, and the specific requirements of temperature and pressure in the system.

Copper vs PVC Infographic

materialdif.com

materialdif.com