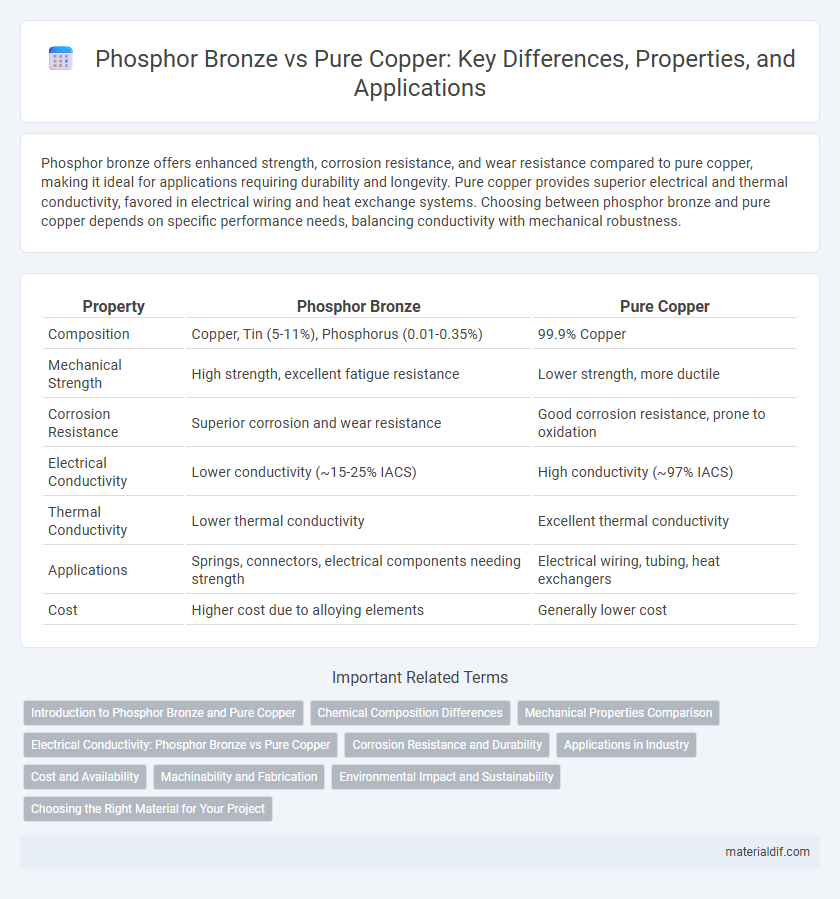

Phosphor bronze offers enhanced strength, corrosion resistance, and wear resistance compared to pure copper, making it ideal for applications requiring durability and longevity. Pure copper provides superior electrical and thermal conductivity, favored in electrical wiring and heat exchange systems. Choosing between phosphor bronze and pure copper depends on specific performance needs, balancing conductivity with mechanical robustness.

Table of Comparison

| Property | Phosphor Bronze | Pure Copper |

|---|---|---|

| Composition | Copper, Tin (5-11%), Phosphorus (0.01-0.35%) | 99.9% Copper |

| Mechanical Strength | High strength, excellent fatigue resistance | Lower strength, more ductile |

| Corrosion Resistance | Superior corrosion and wear resistance | Good corrosion resistance, prone to oxidation |

| Electrical Conductivity | Lower conductivity (~15-25% IACS) | High conductivity (~97% IACS) |

| Thermal Conductivity | Lower thermal conductivity | Excellent thermal conductivity |

| Applications | Springs, connectors, electrical components needing strength | Electrical wiring, tubing, heat exchangers |

| Cost | Higher cost due to alloying elements | Generally lower cost |

Introduction to Phosphor Bronze and Pure Copper

Phosphor bronze is an alloy primarily composed of copper, tin, and a small percentage of phosphorus, known for its enhanced strength, wear resistance, and corrosion resistance compared to pure copper. Pure copper, characterized by its excellent electrical and thermal conductivity, is highly malleable and ductile, making it ideal for electrical wiring and heat exchange applications. The addition of tin and phosphorus in phosphor bronze improves mechanical properties while maintaining good corrosion resistance, distinguishing it from the softer, more conductive pure copper.

Chemical Composition Differences

Phosphor bronze is an alloy primarily composed of copper, typically 88-95%, combined with 0.5-11% tin and 0.01-0.35% phosphorus, which enhances strength, corrosion resistance, and wear resistance. Pure copper, on the other hand, is nearly 99.9% copper with trace impurities but lacks alloying elements like tin and phosphorus, resulting in higher electrical and thermal conductivity but lower mechanical strength. The presence of phosphorus in phosphor bronze reduces friction and improves stiffness, distinguishing its chemical composition and functional properties from pure copper.

Mechanical Properties Comparison

Phosphor bronze exhibits superior mechanical properties compared to pure copper, including higher tensile strength, enhanced fatigue resistance, and improved elasticity. Its alloy composition, typically around 0.5-1.0% phosphorus, increases hardness and wear resistance, making it ideal for applications requiring durability and resilience under mechanical stress. Pure copper, while more ductile and electrically conductive, lacks the mechanical robustness of phosphor bronze, limiting its use in high-stress environments.

Electrical Conductivity: Phosphor Bronze vs Pure Copper

Pure copper exhibits superior electrical conductivity, typically around 59.6 MS/m at room temperature, making it a preferred choice for high-performance electrical applications. Phosphor bronze, an alloy of copper with tin and phosphorus, has lower electrical conductivity, usually ranging between 15 to 20 MS/m, due to the presence of alloying elements which introduce electron scattering. The reduced conductivity of phosphor bronze is offset by its enhanced mechanical strength and corrosion resistance, making it suitable for specialized components where durability is prioritized over maximum electrical performance.

Corrosion Resistance and Durability

Phosphor bronze exhibits superior corrosion resistance compared to pure copper due to the presence of tin and phosphorus, which enhance its ability to withstand oxidation and environmental exposure. The alloy's durability surpasses that of pure copper, offering greater strength and wear resistance, making it ideal for applications requiring long-lasting performance in harsh conditions. Pure copper, while highly conductive, softens easily and corrodes faster without the protective benefits of alloying elements found in phosphor bronze.

Applications in Industry

Phosphor bronze, an alloy of copper with tin and phosphorus, offers superior strength, wear resistance, and corrosion resistance compared to pure copper, making it ideal for applications in electrical connectors, springs, and marine hardware where durability is critical. Pure copper, known for its excellent electrical and thermal conductivity, is predominantly used in electrical wiring, heat exchangers, and plumbing systems where maximum conductivity and flexibility are essential. In industries requiring a balance of mechanical strength and conductivity, phosphor bronze outperforms pure copper, especially in environments exposed to mechanical stress and corrosive elements.

Cost and Availability

Phosphor bronze generally costs more than pure copper due to its alloying elements like tin and phosphorus, which enhance strength and corrosion resistance. Pure copper remains widely available and cheaper, making it the preferred choice for applications prioritizing conductivity and cost-efficiency. Industrial supply chains ensure steady availability of both materials, but pure copper benefits from higher global production and recycling rates.

Machinability and Fabrication

Phosphor bronze exhibits superior machinability compared to pure copper due to its alloy composition, which enhances tool life and reduces wear during machining processes. This alloy's improved strength and wear resistance facilitate easier fabrication for components requiring intricate shapes and fine tolerances. Pure copper, while highly conductive and corrosion-resistant, is softer and more prone to galling, making it less ideal for precision machining applications.

Environmental Impact and Sustainability

Phosphor bronze offers enhanced corrosion resistance and durability compared to pure copper, reducing the frequency of replacements and waste generation, which contributes to environmental sustainability. Pure copper, while highly recyclable and essential for electrical applications, often requires more frequent processing, leading to higher energy consumption and associated emissions. Choosing phosphor bronze in applications with high wear can lower environmental impact through extended material lifespan and reduced resource extraction.

Choosing the Right Material for Your Project

Phosphor bronze offers superior strength, wear resistance, and corrosion resistance compared to pure copper, making it ideal for applications requiring durability and mechanical stability. Pure copper provides excellent electrical and thermal conductivity, suitable for electrical wiring and components where conductivity is paramount. Selecting the right material depends on whether your project prioritizes mechanical performance or conductivity, guiding the choice between phosphor bronze and pure copper.

Phosphor Bronze vs Pure Copper Infographic

materialdif.com

materialdif.com