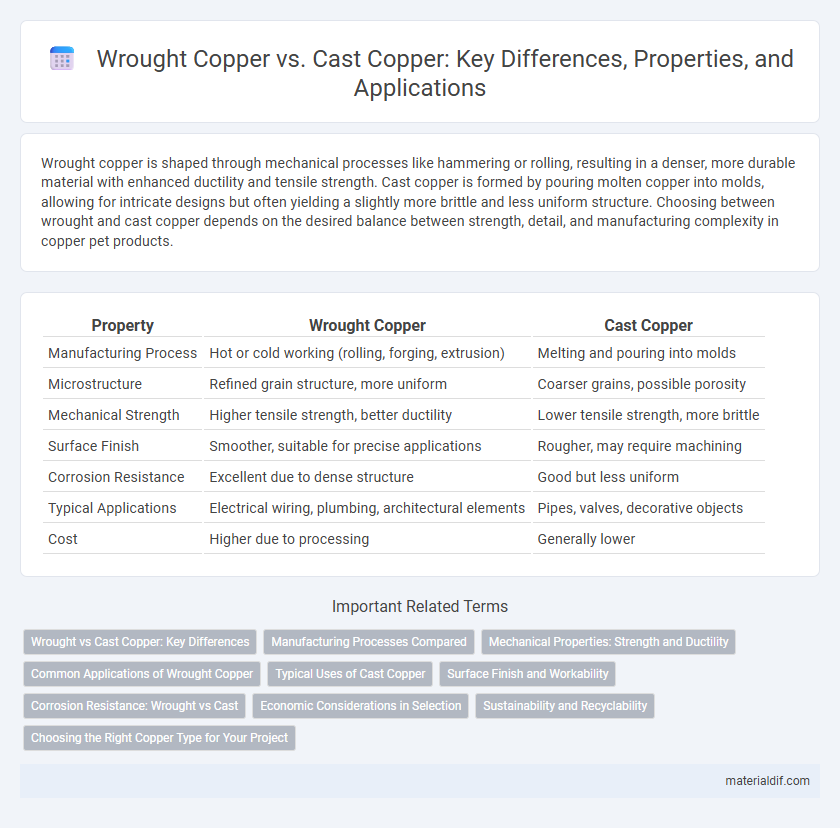

Wrought copper is shaped through mechanical processes like hammering or rolling, resulting in a denser, more durable material with enhanced ductility and tensile strength. Cast copper is formed by pouring molten copper into molds, allowing for intricate designs but often yielding a slightly more brittle and less uniform structure. Choosing between wrought and cast copper depends on the desired balance between strength, detail, and manufacturing complexity in copper pet products.

Table of Comparison

| Property | Wrought Copper | Cast Copper |

|---|---|---|

| Manufacturing Process | Hot or cold working (rolling, forging, extrusion) | Melting and pouring into molds |

| Microstructure | Refined grain structure, more uniform | Coarser grains, possible porosity |

| Mechanical Strength | Higher tensile strength, better ductility | Lower tensile strength, more brittle |

| Surface Finish | Smoother, suitable for precise applications | Rougher, may require machining |

| Corrosion Resistance | Excellent due to dense structure | Good but less uniform |

| Typical Applications | Electrical wiring, plumbing, architectural elements | Pipes, valves, decorative objects |

| Cost | Higher due to processing | Generally lower |

Wrought vs Cast Copper: Key Differences

Wrought copper is mechanically worked through processes like rolling, forging, or drawing, resulting in enhanced strength, uniform grain structure, and improved ductility compared to cast copper. Cast copper is produced by pouring molten copper into molds, allowing complex shapes but often containing porosity and less uniform microstructure, which can reduce mechanical properties. The key differences lie in manufacturing methods, mechanical properties, and typical applications, with wrought copper favored for structural uses and cast copper suited for intricate designs.

Manufacturing Processes Compared

Wrought copper undergoes mechanical deformation processes such as rolling, extruding, and forging, resulting in enhanced strength and improved ductility due to the alignment of its grain structure. In contrast, cast copper is produced by melting and pouring the metal into molds, which allows for complex shapes but often leads to coarser grain structure and potential internal defects. The manufacturing choice impacts the material's mechanical properties and suitability for applications requiring specific strength, toughness, or intricate geometries.

Mechanical Properties: Strength and Ductility

Wrought copper exhibits superior ductility compared to cast copper due to its refined grain structure achieved through mechanical deformation processes like rolling or hammering. Cast copper, while typically stronger in compression because of its solidified microstructure, often has lower tensile strength and is more brittle, making it prone to cracking under stress. The enhanced mechanical properties of wrought copper, including higher tensile strength and elongation, make it preferable for applications requiring flexibility and durability.

Common Applications of Wrought Copper

Wrought copper is widely used in electrical wiring, plumbing, and roofing due to its excellent ductility and corrosion resistance. Its ability to be easily shaped and joined makes it ideal for manufacturing pipes, tubes, and architectural elements. Common applications also include heat exchangers and industrial machinery components where strength and conductivity are essential.

Typical Uses of Cast Copper

Cast copper is commonly used in applications requiring complex shapes and high strength, such as electrical connectors, sculptures, and plumbing fixtures. Its excellent thermal and electrical conductivity makes it ideal for manufacturing heat exchangers and motor parts. The material's durability and corrosion resistance also suit marine hardware and industrial machinery components.

Surface Finish and Workability

Wrought copper offers a smoother and more uniform surface finish compared to cast copper, due to its processing through rolling or hammering which aligns the metal's grain structure. This enhancement in surface texture allows for improved aesthetic appeal and better paint or plating adhesion. In terms of workability, wrought copper is more malleable and ductile, making it ideal for applications that require bending, shaping, or intricate detailing, whereas cast copper is more brittle and prone to surface imperfections, limiting its use in precision components.

Corrosion Resistance: Wrought vs Cast

Wrought copper demonstrates superior corrosion resistance compared to cast copper due to its refined grain structure and uniform composition, which reduce susceptibility to pitting and stress corrosion cracking. Cast copper, with its coarser microstructure and potential porosity, often exhibits localized corrosion, especially in aggressive environments. This makes wrought copper the preferred choice for applications requiring enhanced durability and long-term exposure to corrosive elements.

Economic Considerations in Selection

Wrought copper typically offers superior mechanical properties and corrosion resistance, justifying its higher initial cost in applications demanding durability and precision. Cast copper, being less expensive to produce due to simpler manufacturing processes, suits components where complex shapes are essential and mechanical stress is lower. Economic selection hinges on balancing upfront material costs against long-term performance benefits and machining expenses.

Sustainability and Recyclability

Wrought copper presents superior sustainability due to its lower energy consumption during production and enhanced recyclability compared to cast copper, which requires higher temperatures and energy-intensive molds. Both forms are highly recyclable, but wrought copper's processing enables repeated reuse with minimal material degradation, supporting circular economy principles. Choosing wrought copper reduces environmental impact by minimizing waste and promoting efficient resource utilization in manufacturing.

Choosing the Right Copper Type for Your Project

Wrought copper offers superior strength, malleability, and corrosion resistance, making it ideal for applications requiring precise shaping and durability, such as plumbing and electrical components. Cast copper, produced by pouring molten copper into molds, suits complex shapes and heavy-duty parts but typically lacks the mechanical robustness of wrought copper. Selecting the right copper type depends on project requirements like mechanical strength, form complexity, and cost-effectiveness.

Wrought Copper vs Cast Copper Infographic

materialdif.com

materialdif.com