Copper clad steel combines the high conductivity of copper with the strength and durability of steel, making it ideal for applications requiring both electrical efficiency and mechanical toughness. Pure copper offers superior electrical and thermal conductivity, corrosion resistance, and malleability, which makes it the preferred choice for wiring and electronic components where performance is critical. The choice between copper clad steel and pure copper depends on balancing cost, conductivity requirements, and mechanical strength for specific industrial or electrical uses.

Table of Comparison

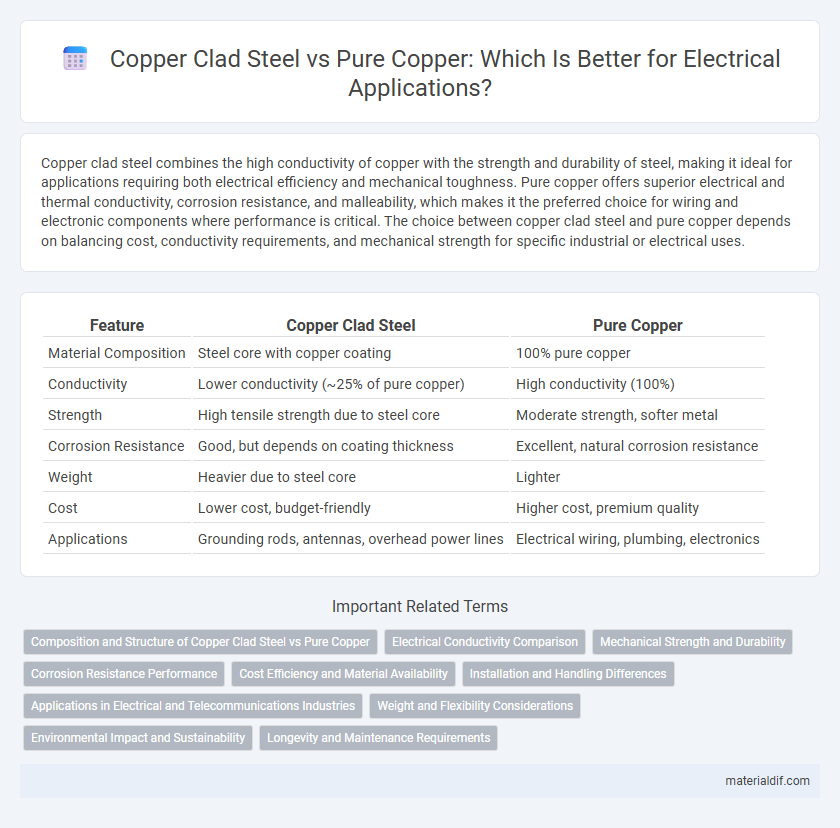

| Feature | Copper Clad Steel | Pure Copper |

|---|---|---|

| Material Composition | Steel core with copper coating | 100% pure copper |

| Conductivity | Lower conductivity (~25% of pure copper) | High conductivity (100%) |

| Strength | High tensile strength due to steel core | Moderate strength, softer metal |

| Corrosion Resistance | Good, but depends on coating thickness | Excellent, natural corrosion resistance |

| Weight | Heavier due to steel core | Lighter |

| Cost | Lower cost, budget-friendly | Higher cost, premium quality |

| Applications | Grounding rods, antennas, overhead power lines | Electrical wiring, plumbing, electronics |

Composition and Structure of Copper Clad Steel vs Pure Copper

Copper Clad Steel consists of a steel core surrounded by a layer of pure copper, combining the high tensile strength of steel with copper's excellent electrical conductivity and corrosion resistance. Pure copper is a homogeneous metal with superior malleability and conductivity but lacks the mechanical strength offered by the steel core in copper clad steel. The composite structure of copper clad steel enables cost savings and enhanced durability for applications requiring both electrical performance and mechanical robustness.

Electrical Conductivity Comparison

Copper clad steel offers a balance between strength and conductivity, with electrical conductivity typically around 20-30% of pure copper's conductivity, which is approximately 5.96x10^7 S/m. Pure copper exhibits superior electrical conductivity, making it ideal for applications requiring minimal energy loss and efficient signal transmission. The reduced conductivity of copper clad steel results from its steel core, which has significantly lower conductivity but enhanced mechanical strength.

Mechanical Strength and Durability

Copper Clad Steel offers superior mechanical strength compared to pure copper due to its steel core, making it highly resistant to stretching and breaking under stress. Its enhanced durability is ideal for applications requiring both conductivity and robustness, such as overhead power lines and grounding systems. Pure copper, while excellent in electrical conductivity, tends to be softer and more prone to wear and deformation over time.

Corrosion Resistance Performance

Copper clad steel offers enhanced mechanical strength but exhibits lower corrosion resistance compared to pure copper due to the steel core's susceptibility to rust. Pure copper provides superior corrosion resistance in various environments, maintaining conductivity and durability over time. In marine and industrial applications, pure copper's resistance to oxidation and chemical degradation makes it the preferred choice for longevity.

Cost Efficiency and Material Availability

Copper clad steel offers superior cost efficiency compared to pure copper due to its lower raw material expenses and reduced manufacturing costs, making it ideal for budget-sensitive applications. The availability of copper clad steel is generally higher because it uses a steel core, which is more abundant and less affected by copper market fluctuations. Pure copper, while more expensive and sometimes limited by supply constraints, provides better electrical conductivity and corrosion resistance, influencing its selection despite higher costs.

Installation and Handling Differences

Copper clad steel offers greater tensile strength and rigidity, making it easier to install in overhead or long-span applications without sagging. Pure copper is more ductile and flexible, allowing smoother bending and handling during complex installations but can be prone to kinking. While copper clad steel reduces the risk of damage under mechanical stress, pure copper provides superior conductivity and corrosion resistance, influencing the choice based on installation demands.

Applications in Electrical and Telecommunications Industries

Copper clad steel offers a cost-effective alternative to pure copper in electrical and telecommunications industries, combining the high conductivity of copper with the tensile strength of steel. It is extensively used in grounding systems, coaxial cables, and overhead power lines where durability and electrical performance are critical. Pure copper remains preferred for applications requiring maximum conductivity and corrosion resistance, such as printed circuit boards, wiring harnesses, and high-frequency signal transmission cables.

Weight and Flexibility Considerations

Copper clad steel offers a lighter weight alternative to pure copper due to its steel core, which reduces material density while maintaining adequate conductivity. Pure copper provides superior flexibility and less brittleness, making it ideal for applications requiring frequent bending and manipulation. Weight-sensitive projects benefit from copper clad steel's durability, whereas flexible wiring systems favor the malleability of pure copper for optimal performance.

Environmental Impact and Sustainability

Copper Clad Steel offers a lower environmental impact compared to pure copper due to reduced copper mining requirements and enhanced recyclability of the steel core. Pure copper, while highly conductive and corrosion-resistant, demands extensive mining that contributes to habitat destruction and higher carbon emissions. Utilizing Copper Clad Steel balances material performance with sustainability goals by minimizing resource extraction and promoting metal reuse.

Longevity and Maintenance Requirements

Copper clad steel offers enhanced strength and durability compared to pure copper, making it more resistant to damage and wear over time. Pure copper excels in corrosion resistance and requires minimal maintenance, ensuring exceptional longevity in environments prone to oxidation. Maintenance of copper clad steel may involve periodic inspections for rust, while pure copper primarily demands cleaning to maintain its conductive properties.

Copper Clad Steel vs Pure Copper Infographic

materialdif.com

materialdif.com