Red copper, known for its high purity and excellent electrical conductivity, is primarily composed of nearly pure copper with minimal alloying elements, giving it a distinctive reddish color. White copper, often an alloy such as nickel silver or cupronickel, combines copper with metals like nickel and zinc to enhance corrosion resistance and mechanical strength while exhibiting a silvery appearance. These differences in composition and properties make red copper ideal for electrical applications and white copper suitable for decorative and marine uses.

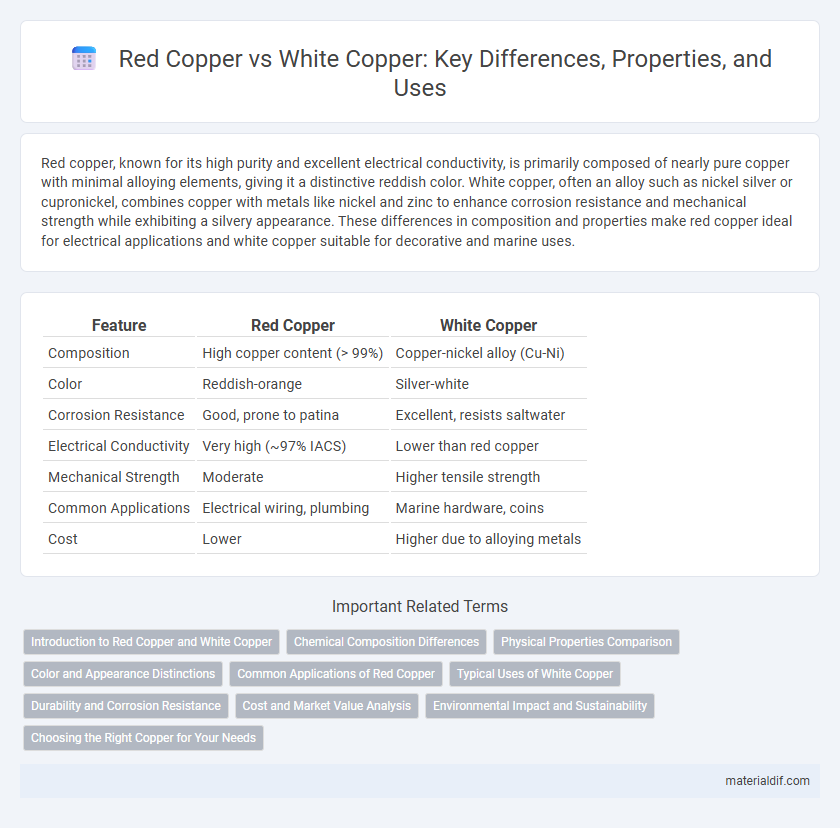

Table of Comparison

| Feature | Red Copper | White Copper |

|---|---|---|

| Composition | High copper content (> 99%) | Copper-nickel alloy (Cu-Ni) |

| Color | Reddish-orange | Silver-white |

| Corrosion Resistance | Good, prone to patina | Excellent, resists saltwater |

| Electrical Conductivity | Very high (~97% IACS) | Lower than red copper |

| Mechanical Strength | Moderate | Higher tensile strength |

| Common Applications | Electrical wiring, plumbing | Marine hardware, coins |

| Cost | Lower | Higher due to alloying metals |

Introduction to Red Copper and White Copper

Red copper, also known as pure copper, is characterized by its distinct reddish color and exceptional thermal and electrical conductivity, making it highly suitable for electrical wiring and plumbing applications. White copper typically refers to copper alloys such as cupronickel, which combine copper with nickel to enhance corrosion resistance and mechanical strength, commonly used in marine environments and coinage. Understanding the differences in composition and properties between red copper and white copper is essential for selecting the appropriate material for specific industrial and commercial uses.

Chemical Composition Differences

Red copper primarily consists of nearly pure copper with minimal impurities, providing its characteristic reddish color due to the absence of alloying elements. White copper, often referred to as cupronickel, contains significant amounts of nickel (typically 10-30%) along with copper, resulting in a silver-white appearance and enhanced corrosion resistance. The key chemical composition difference lies in the high purity of copper in red copper versus the copper-nickel alloy ratio in white copper.

Physical Properties Comparison

Red copper exhibits a higher electrical conductivity of approximately 58 MS/m and a melting point near 1085degC, whereas white copper alloys, such as cupronickel, have lower conductivity values around 22 MS/m and melting points ranging from 1170degC to 1240degC. The density of red copper is about 8.96 g/cm3, significantly higher than white copper alloys which typically range between 8.9 and 9.2 g/cm3 depending on their nickel content. Tensile strength varies with composition, as red copper maintains moderate strength around 210 MPa, while white copper alloys can reach tensile strengths exceeding 400 MPa due to alloying elements like nickel and zinc.

Color and Appearance Distinctions

Red copper exhibits a deep reddish-orange hue due to its high copper content, which enhances its natural warm and vibrant appearance. White copper, often an alloy such as cupronickel, displays a silver-white or pale gray color that mimics the look of nickel or silver metals. These distinct color differences make red copper preferred for decorative and architectural applications while white copper is favored for corrosion resistance and industrial uses.

Common Applications of Red Copper

Red copper, known for its high purity and excellent electrical conductivity, is commonly used in electrical wiring, plumbing, and industrial machinery components. Its superior thermal conductivity and corrosion resistance make it ideal for applications such as heat exchangers, roofing, and decorative architectural elements. Red copper's antimicrobial properties also enable its use in healthcare settings and water distribution systems to reduce the risk of bacterial growth.

Typical Uses of White Copper

White copper, an alloy primarily composed of copper, nickel, and zinc, is commonly used in the production of coins, jewelry, and cutlery due to its durability and corrosion resistance. Its silvery-white appearance and high strength make it ideal for decorative items and industrial applications where aesthetic appeal and mechanical stability are essential. Typical uses also include electrical components and plumbing fixtures, benefiting from its excellent conductivity and resistance to oxidation.

Durability and Corrosion Resistance

Red copper exhibits superior durability and corrosion resistance due to its higher purity and minimal alloying elements, making it ideal for plumbing and electrical applications. White copper, an alloy typically containing nickel and zinc, offers enhanced strength but is more prone to corrosion in moist environments compared to red copper. The inherent properties of red copper ensure longer lifespan and reduced maintenance costs in critical infrastructure settings.

Cost and Market Value Analysis

Red copper, characterized by its high purity of approximately 99.9% copper, commands a higher market value due to superior electrical conductivity and corrosion resistance compared to white copper, which is a copper-nickel alloy with lower copper content. The cost of red copper is generally elevated because of its refined extraction and processing, making it preferred in electrical wiring and plumbing applications with stringent performance standards. White copper offers a more affordable alternative with robust corrosion resistance, commonly used in marine hardware and decorative items, reflecting a lower but stable market demand influenced by nickel pricing fluctuations.

Environmental Impact and Sustainability

Red copper, primarily composed of pure copper with minimal alloying elements, offers superior recyclability and lower environmental impact due to its high conductivity and durability, reducing energy consumption over its lifecycle. White copper, often an alloy such as nickel silver, involves additional metals that increase mining demand and energy-intensive processing, contributing to greater carbon emissions and resource depletion. Sustainable practices favor red copper for its efficiency in recycling loops and reduced ecological footprint, aligning with green building standards and circular economy principles.

Choosing the Right Copper for Your Needs

Red copper, known for its high purity of approximately 99.9% copper content, offers excellent electrical conductivity and corrosion resistance, making it ideal for electrical wiring and plumbing applications. White copper, often a copper-nickel alloy, provides enhanced strength and resistance to seawater corrosion, suitable for marine equipment and industrial uses. Selecting between red and white copper depends on balancing conductivity requirements with mechanical strength and environmental exposure.

Red Copper vs White Copper Infographic

materialdif.com

materialdif.com