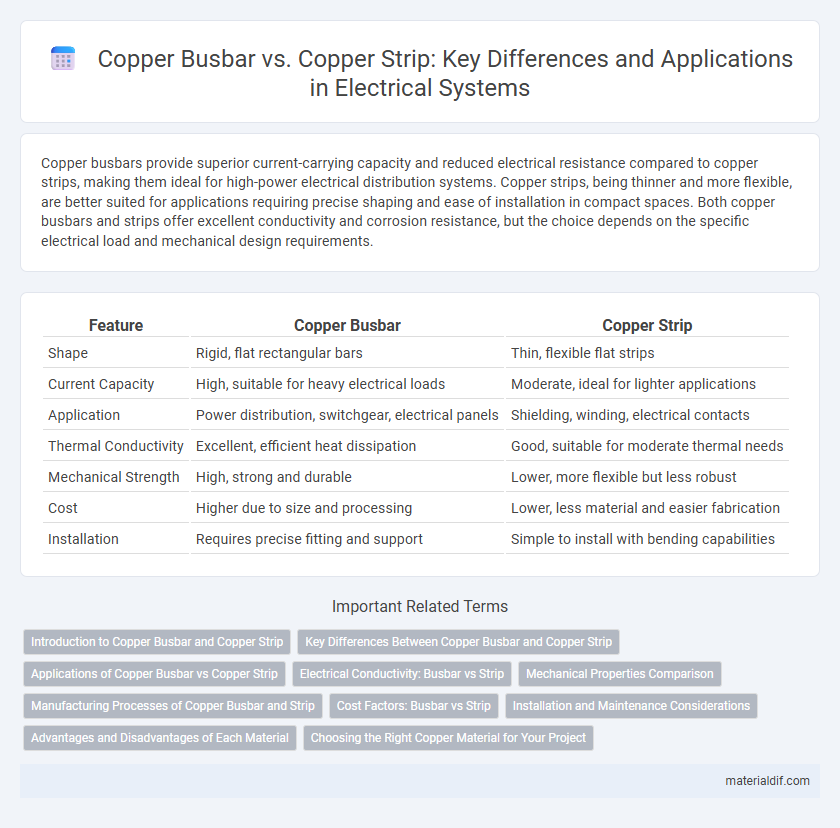

Copper busbars provide superior current-carrying capacity and reduced electrical resistance compared to copper strips, making them ideal for high-power electrical distribution systems. Copper strips, being thinner and more flexible, are better suited for applications requiring precise shaping and ease of installation in compact spaces. Both copper busbars and strips offer excellent conductivity and corrosion resistance, but the choice depends on the specific electrical load and mechanical design requirements.

Table of Comparison

| Feature | Copper Busbar | Copper Strip |

|---|---|---|

| Shape | Rigid, flat rectangular bars | Thin, flexible flat strips |

| Current Capacity | High, suitable for heavy electrical loads | Moderate, ideal for lighter applications |

| Application | Power distribution, switchgear, electrical panels | Shielding, winding, electrical contacts |

| Thermal Conductivity | Excellent, efficient heat dissipation | Good, suitable for moderate thermal needs |

| Mechanical Strength | High, strong and durable | Lower, more flexible but less robust |

| Cost | Higher due to size and processing | Lower, less material and easier fabrication |

| Installation | Requires precise fitting and support | Simple to install with bending capabilities |

Introduction to Copper Busbar and Copper Strip

Copper busbars are thick, rigid conductors designed for efficient electrical power distribution in switchgear, panel boards, and transformers, offering superior current-carrying capacity and minimal resistance. Copper strips, thinner and more flexible than busbars, serve as connectors and grounding components in electrical circuits, providing excellent conductivity and ease of installation in compact spaces. Both copper busbars and strips utilize the metal's high electrical conductivity and corrosion resistance, with selection depending on application requirements such as current load and mechanical stability.

Key Differences Between Copper Busbar and Copper Strip

Copper busbars offer high current-carrying capacity and excellent thermal conductivity, making them ideal for power distribution in electrical panels and switchgear. Copper strips are thinner and more flexible, suited for grounding, bonding, and low-power electrical applications. The key differences lie in their thickness, mechanical strength, and typical usage environments, with busbars designed for heavy-duty electrical loads and copper strips for lighter, more flexible electrical connections.

Applications of Copper Busbar vs Copper Strip

Copper busbars are extensively used in power distribution systems, electrical panels, and switchgear due to their superior conductivity and ability to handle high current loads efficiently. Copper strips find applications in grounding systems, electrical terminals, and battery connections where flexibility and ease of installation are critical. Both materials optimize electrical performance but are selected based on current capacity, mechanical strength, and space constraints in various industrial and electrical engineering contexts.

Electrical Conductivity: Busbar vs Strip

Copper busbars exhibit superior electrical conductivity compared to copper strips due to their larger cross-sectional area, which reduces electrical resistance and enhances current-carrying capacity. The thickness and width of busbars allow for efficient heat dissipation and minimal voltage drop, making them ideal for high-power electrical distribution. While copper strips offer good conductivity, their smaller dimensions limit current flow and increase resistance relative to busbars, impacting overall performance in heavy-duty applications.

Mechanical Properties Comparison

Copper busbars exhibit superior mechanical strength and rigidity compared to copper strips, making them ideal for high-current electrical applications requiring robust support and durability. The thicker cross-sectional area of copper busbars enhances their resistance to bending and deformation under mechanical stress, while copper strips, being thinner and more flexible, offer easier installation but lower tensile strength. Optimal selection depends on balancing mechanical demands with design flexibility in electrical power distribution systems.

Manufacturing Processes of Copper Busbar and Strip

Copper busbars undergo a hot rolling process followed by precise cutting and annealing to achieve uniform thickness and enhanced electrical conductivity, ensuring optimal performance in power distribution systems. Copper strips are typically produced through cold rolling, which results in superior surface finish and tighter thickness tolerances, making them ideal for electronic components and industrial applications. Both manufacturing processes emphasize strict quality control and tailored heat treatments to meet specific conductivity and mechanical strength requirements.

Cost Factors: Busbar vs Strip

Copper busbars typically incur higher material and manufacturing costs due to their larger volume and need for precise cutting and shaping compared to thinner copper strips. Copper strips offer cost advantages in applications requiring flexibility and compactness, as they use less material and can be produced in continuous rolls. Maintenance costs for busbars may be lower because of their robust design and ease of installation, whereas copper strips might require more frequent inspection and replacement in high-stress environments.

Installation and Maintenance Considerations

Copper busbars offer straightforward installation due to their rigid, bar-shaped design, allowing for secure bolted or welded connections that minimize electrical resistance and heat buildup. In contrast, copper strips are more flexible and easier to cut or bend, which facilitates custom fitting in tight or irregular spaces but may require additional support to maintain stability during operation. Maintenance of copper busbars typically involves less frequent inspections for wear or corrosion, whereas copper strips demand regular checks due to their susceptibility to mechanical stress and potential surface oxidation.

Advantages and Disadvantages of Each Material

Copper busbars offer superior current-carrying capacity and excellent thermal conductivity, making them ideal for high-power electrical distribution and industrial applications, though they tend to be heavier and less flexible than copper strips. Copper strips provide better flexibility and ease of installation in compact electrical assemblies but generally have lower current-carrying capacity and higher resistance compared to busbars. Choosing between copper busbars and strips depends on balancing conductivity requirements, mechanical strength, and space constraints in specific electrical system designs.

Choosing the Right Copper Material for Your Project

Copper busbars offer superior current-carrying capacity and efficient heat dissipation, making them ideal for high-power electrical distribution and industrial applications. Copper strips provide flexibility and ease of installation, suited for grounding, electrical connections, and custom-sized components where space constraints exist. Selecting between copper busbars and strips depends on factors like electrical load requirements, mechanical strength, and specific project design needs to ensure optimal performance and durability.

Copper Busbar vs Copper Strip Infographic

materialdif.com

materialdif.com