Copper pipe and copper tube differ primarily in manufacturing and application, with copper pipe being thicker and generally used for plumbing and structural purposes, while copper tube is thinner, available in precise dimensions, and ideal for HVAC and refrigeration systems. Copper pipe is measured by nominal size, which may not reflect the actual dimensions, whereas copper tube is measured by outside diameter for accuracy in fittings. Selecting between copper pipe and tube depends on the specific project requirements, including pressure ratings, flexibility, and standard compliance.

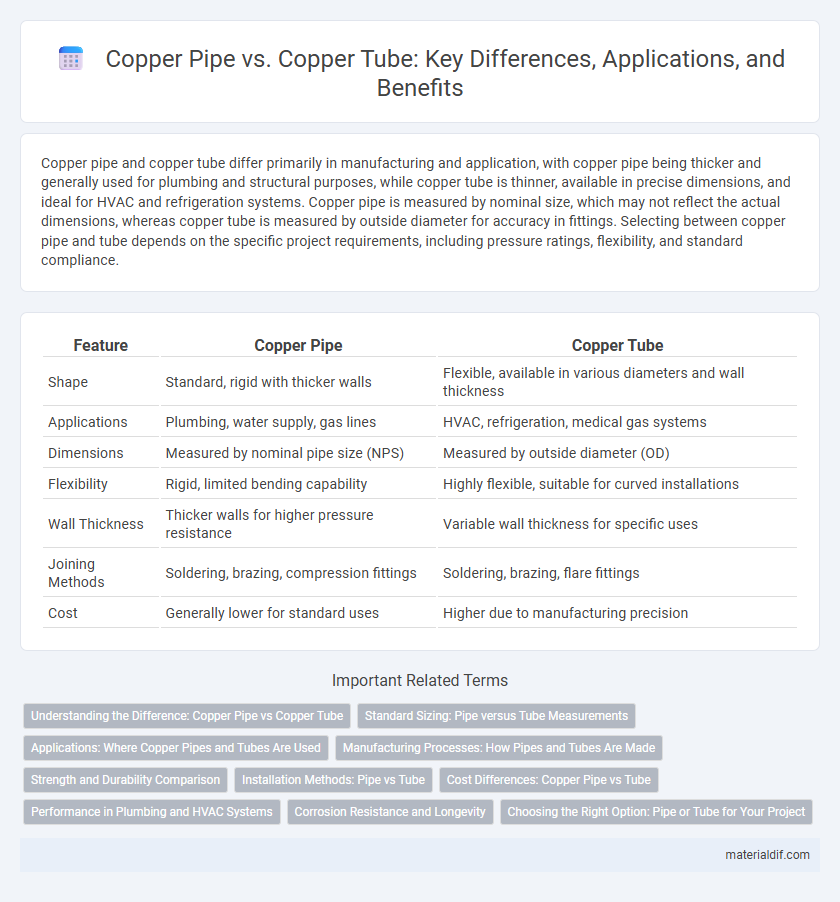

Table of Comparison

| Feature | Copper Pipe | Copper Tube |

|---|---|---|

| Shape | Standard, rigid with thicker walls | Flexible, available in various diameters and wall thickness |

| Applications | Plumbing, water supply, gas lines | HVAC, refrigeration, medical gas systems |

| Dimensions | Measured by nominal pipe size (NPS) | Measured by outside diameter (OD) |

| Flexibility | Rigid, limited bending capability | Highly flexible, suitable for curved installations |

| Wall Thickness | Thicker walls for higher pressure resistance | Variable wall thickness for specific uses |

| Joining Methods | Soldering, brazing, compression fittings | Soldering, brazing, flare fittings |

| Cost | Generally lower for standard uses | Higher due to manufacturing precision |

Understanding the Difference: Copper Pipe vs Copper Tube

Copper pipe and copper tube differ primarily in manufacturing methods and applications; copper pipe is typically manufactured to specific dimensions with thicker walls for plumbing systems, ensuring durability and pressure resistance. Copper tube, with thinner walls and more precise dimensions, is commonly used in HVAC and refrigeration applications requiring tighter tolerances and easier bending. Understanding these differences helps select the appropriate material based on strength, flexibility, and installation needs in construction and industrial projects.

Standard Sizing: Pipe versus Tube Measurements

Copper pipe and copper tube differ primarily in their standard sizing measurements, where copper pipes are measured by their nominal pipe size (NPS), reflecting the approximate inside diameter, while copper tubes are measured by their outside diameter (OD) for precision applications. Pipe sizing follows ASTM standards such as ASTM B88, commonly used for plumbing, with standard wall thicknesses dictating flow capacity and pressure ratings. Copper tubing, often utilized in HVAC and refrigeration, provides tighter tolerances and consistent dimensions critical for fittings and system integrity.

Applications: Where Copper Pipes and Tubes Are Used

Copper pipes are primarily used in plumbing systems for water supply and distribution, thanks to their durability and resistance to corrosion. Copper tubes find applications in HVAC systems, refrigeration, and medical gas delivery, where precision and flexibility are critical. The choice between copper pipe and tube depends on the specific needs of the project, including pressure ratings and installation requirements.

Manufacturing Processes: How Pipes and Tubes Are Made

Copper pipes are typically manufactured through a hot extrusion process, where a copper billet is heated and forced through a die to create a hollow cylindrical shape with thicker walls, ensuring durability for plumbing and industrial applications. Copper tubes are produced using a continuous casting method combined with rolling and drawing to achieve thinner walls and tighter tolerances, making them ideal for HVAC systems and medical equipment. Both processes emphasize precise control over metal thickness and surface finish to meet specific industry standards such as ASTM B88 for pipes and ASTM B-75 for tubes.

Strength and Durability Comparison

Copper pipe and copper tube differ primarily in wall thickness, impacting their strength and durability; copper pipe typically has a thicker wall, providing greater pressure resistance and longevity for plumbing applications. Copper tubing, often classified as Type M, L, or K, varies in thickness with Type K being the thickest and most durable, suitable for high-pressure needs and outdoor use. The enhanced strength of copper pipe makes it ideal for structural support in plumbing, while copper tube's flexibility and specific grade classifications tailor it to various durability requirements.

Installation Methods: Pipe vs Tube

Copper pipe installation typically uses threaded or soldered fittings, requiring precise joint preparation and the use of flux or sealant for leak-proof connections. Copper tubing installation often involves flared or compression fittings, allowing for easier assembly and disassembly without soldering, ideal for HVAC or refrigeration systems. Both methods demand careful handling to avoid kinks and maintain integrity, but tubing offers more flexibility and faster installation in tight or complex layouts.

Cost Differences: Copper Pipe vs Tube

Copper pipe generally costs less than copper tube due to its thicker walls and simpler manufacturing process, making it preferred for residential plumbing where durability is key. Copper tube, often used in HVAC and refrigeration, has thinner walls and tighter tolerances, resulting in higher material and production costs. Price differences are influenced by purity, wall thickness, and intended application, with tubes demanding precision that adds to the overall expense.

Performance in Plumbing and HVAC Systems

Copper pipe offers superior strength and durability, making it ideal for high-pressure plumbing and HVAC applications. Copper tubing provides greater flexibility and easier installation for complex layouts, with comparable corrosion resistance to pipes. Both materials ensure excellent thermal conductivity and long-term performance in residential and commercial systems.

Corrosion Resistance and Longevity

Copper pipes and copper tubes differ primarily in manufacturing process and wall thickness, impacting their corrosion resistance and longevity. Copper pipes, often thicker and rigid, offer superior durability and enhanced resistance to corrosion in plumbing and heating systems. Copper tubes, typically thinner and more flexible, may be more susceptible to corrosion over time but are preferred for applications needing easy bending and installation.

Choosing the Right Option: Pipe or Tube for Your Project

Copper pipes have standardized dimensions and thicker walls, making them ideal for plumbing and water supply systems requiring durability and pressure resistance. Copper tubes, with their precise dimensions and thinner walls, are preferred in HVAC, refrigeration, and medical gas applications where flexibility and accurate fittings are essential. Selecting the right option depends on the specific project requirements, including pressure ratings, corrosion resistance, and installation needs.

Copper Pipe vs Copper Tube Infographic

materialdif.com

materialdif.com