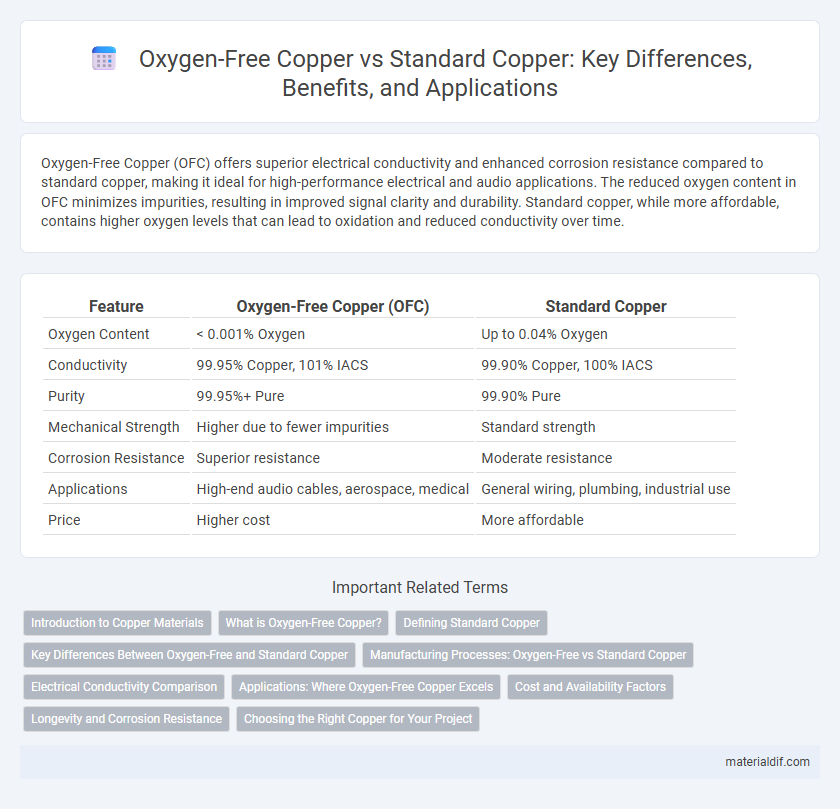

Oxygen-Free Copper (OFC) offers superior electrical conductivity and enhanced corrosion resistance compared to standard copper, making it ideal for high-performance electrical and audio applications. The reduced oxygen content in OFC minimizes impurities, resulting in improved signal clarity and durability. Standard copper, while more affordable, contains higher oxygen levels that can lead to oxidation and reduced conductivity over time.

Table of Comparison

| Feature | Oxygen-Free Copper (OFC) | Standard Copper |

|---|---|---|

| Oxygen Content | < 0.001% Oxygen | Up to 0.04% Oxygen |

| Conductivity | 99.95% Copper, 101% IACS | 99.90% Copper, 100% IACS |

| Purity | 99.95%+ Pure | 99.90% Pure |

| Mechanical Strength | Higher due to fewer impurities | Standard strength |

| Corrosion Resistance | Superior resistance | Moderate resistance |

| Applications | High-end audio cables, aerospace, medical | General wiring, plumbing, industrial use |

| Price | Higher cost | More affordable |

Introduction to Copper Materials

Oxygen-Free Copper (OFC) is a high-purity copper material containing 99.95% or higher copper content with extremely low oxygen levels, typically below 0.001%. Standard copper, often known as Electrolytic Tough Pitch (ETP) copper, contains oxygen levels around 0.02% to 0.04%, which affects its electrical and thermal conductivity properties. OFC is preferred in high-performance applications such as audio cables, electrical connectors, and vacuum systems due to its enhanced conductivity and resistance to oxidation compared to standard copper.

What is Oxygen-Free Copper?

Oxygen-Free Copper (OFC) is a highly pure copper material refined to contain less than 0.001% oxygen, offering superior electrical conductivity and corrosion resistance compared to standard copper. Unlike standard copper, which typically contains small amounts of oxygen that can cause impurities and reduce performance, OFC provides enhanced signal transmission and durability, making it ideal for high-end audio cables, electrical wiring, and industrial applications. The minimal oxygen content in OFC prevents the formation of copper oxides, ensuring greater mechanical strength and long-term reliability in critical electrical components.

Defining Standard Copper

Standard copper, commonly known as electrolytic tough pitch (ETP) copper, contains a small amount of oxygen, typically around 0.02% to 0.04%, which enhances its electrical conductivity and mechanical strength. This form of copper is widely used in electrical wiring, plumbing, and industrial applications due to its balance of cost, conductivity, and durability. The presence of oxygen in standard copper can, however, lead to issues like hydrogen embrittlement during soldering or welding processes.

Key Differences Between Oxygen-Free and Standard Copper

Oxygen-free copper contains 99.95% or higher purity with minimal oxygen content, enhancing electrical conductivity and corrosion resistance compared to standard copper, which typically contains small amounts of oxygen and impurities. Key differences include oxygen-free copper's improved thermal stability and reduced risk of hydrogen embrittlement during manufacturing, making it ideal for high-performance electrical applications and audio equipment. Standard copper, while more cost-effective, may exhibit lower conductivity and increased susceptibility to oxidation, impacting its efficiency in sensitive electronic components.

Manufacturing Processes: Oxygen-Free vs Standard Copper

Oxygen-Free Copper (OFC) is produced through a controlled melting process in an oxygen-free atmosphere, minimizing oxygen content to below 0.001%, which enhances electrical conductivity and purity. Standard copper undergoes conventional smelting and refining, where small amounts of oxygen remain, potentially forming copper oxides that affect mechanical and electrical properties. The manufacturing process of OFC involves vacuum melting and casting techniques, ensuring fewer impurities compared to standard copper processing methods.

Electrical Conductivity Comparison

Oxygen-Free Copper (OFC) exhibits higher electrical conductivity compared to Standard Copper, often reaching up to 101% IACS (International Annealed Copper Standard). The reduced oxygen content in OFC minimizes oxidation and impurity-related scattering, enhancing electron mobility and reducing resistive losses. Standard Copper typically has conductivity around 97-99% IACS, making OFC preferable for high-performance electrical applications demanding superior conductivity and reliability.

Applications: Where Oxygen-Free Copper Excels

Oxygen-free copper (OFC) is highly valued in audio and electronic applications due to its superior electrical conductivity and minimal oxygen content, which reduces oxidation and signal loss. This purity makes OFC ideal for high-fidelity audio cables, aerospace wiring, and sensitive electronic devices that demand consistent conductivity and durability. In contrast, standard copper, which contains trace oxygen, is more suited for general electrical wiring where cost efficiency is prioritized over maximum performance.

Cost and Availability Factors

Oxygen-Free Copper (OFC) typically commands a higher price than standard copper due to its refined manufacturing process that ensures minimal oxygen content, enhancing conductivity and corrosion resistance. Standard copper, being more abundant and widely produced, offers greater availability and lower cost for general industrial applications. Cost-sensitive projects often favor standard copper despite OFC's superior performance in specialized electronics and audio equipment.

Longevity and Corrosion Resistance

Oxygen-Free Copper (OFC) exhibits superior longevity compared to standard copper due to its higher purity and reduced oxygen content, which minimizes internal oxidation and grain boundary degradation. This enhanced purity significantly improves corrosion resistance, preventing the formation of copper oxides and prolonging the material's functional lifespan in demanding environments. Standard copper, containing trace oxygen impurities, is more susceptible to corrosion, resulting in decreased durability and frequent maintenance requirements.

Choosing the Right Copper for Your Project

Oxygen-Free Copper (OFC) offers superior electrical conductivity and corrosion resistance compared to Standard Copper, making it ideal for high-performance electronic and audio applications. Standard Copper remains cost-effective and sufficient for general wiring, plumbing, and construction projects where ultra-pure conductivity is less critical. Selecting the right copper depends on project requirements, with OFC preferred for precision and longevity, while Standard Copper suits budget-conscious, everyday use.

Oxygen-Free Copper vs Standard Copper Infographic

materialdif.com

materialdif.com