Copper busbars offer superior electrical conductivity and efficient heat dissipation compared to copper rods, making them ideal for high-current applications and electrical distribution systems. Their flat, rectangular shape ensures uniform current flow and easier connection to busbar systems, whereas copper rods are cylindrical and better suited for grounding and smaller-scale electrical uses. Choosing between copper busbars and copper rods depends on the specific requirements of conductivity, mechanical strength, and installation configuration in electrical projects.

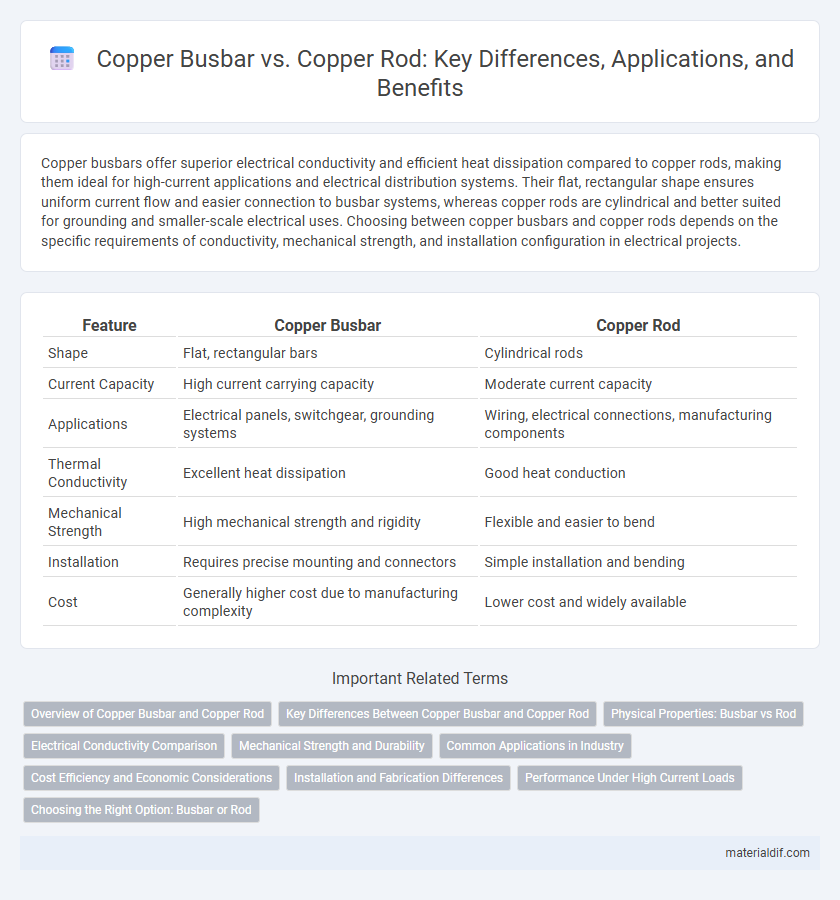

Table of Comparison

| Feature | Copper Busbar | Copper Rod |

|---|---|---|

| Shape | Flat, rectangular bars | Cylindrical rods |

| Current Capacity | High current carrying capacity | Moderate current capacity |

| Applications | Electrical panels, switchgear, grounding systems | Wiring, electrical connections, manufacturing components |

| Thermal Conductivity | Excellent heat dissipation | Good heat conduction |

| Mechanical Strength | High mechanical strength and rigidity | Flexible and easier to bend |

| Installation | Requires precise mounting and connectors | Simple installation and bending |

| Cost | Generally higher cost due to manufacturing complexity | Lower cost and widely available |

Overview of Copper Busbar and Copper Rod

Copper busbars provide efficient electrical conductivity and are widely used in power distribution systems due to their flat, rectangular shape that offers excellent surface area for current flow. Copper rods, characterized by their cylindrical form, are typically utilized in wire manufacturing and grounding applications, offering high tensile strength and flexibility. Both components leverage copper's superior conductivity and corrosion resistance but differ significantly in application based on shape and mechanical properties.

Key Differences Between Copper Busbar and Copper Rod

Copper busbars offer superior electrical conductivity and heat dissipation compared to copper rods, making them ideal for high-current power distribution systems. Copper rods provide greater mechanical strength and flexibility, commonly used in grounding and electrical wiring applications. The flat, wide shape of busbars reduces resistance and improves energy efficiency, whereas rods, being cylindrical, cater to portability and ease of installation.

Physical Properties: Busbar vs Rod

Copper busbars exhibit a flat, rectangular cross-section that enhances their surface area for efficient heat dissipation and electrical conductivity, making them ideal for high-current applications. Copper rods, with their cylindrical shape, offer uniform mechanical strength and ease of machining, suitable for structural and electrical components requiring tensile durability. The physical differences influence thermal performance, electrical resistance, and mechanical stability between busbars and rods in copper-based systems.

Electrical Conductivity Comparison

Copper busbars exhibit superior electrical conductivity compared to copper rods due to their larger cross-sectional area and lower resistance, making them ideal for high-current applications in electrical panels and switchgear. Copper rods, while also highly conductive, are typically used in wire manufacturing where flexibility and ease of installation are prioritized over maximum conductivity. The specific conductivity of copper busbars often reaches 58 MS/m (megasiemens per meter), closely matching the theoretical conductivity of pure copper, whereas copper rods may have slightly lower effective conductivity due to surface oxidation and mechanical processing.

Mechanical Strength and Durability

Copper busbars exhibit superior mechanical strength and durability compared to copper rods due to their optimized flat and wide surface design, which distributes mechanical stress more evenly. The enhanced rigidity and resistance to bending make copper busbars ideal for high-load electrical applications where robust structural integrity is critical. Copper rods, while flexible and easier to shape, typically offer lower mechanical strength, making them less durable in environments subject to mechanical strain.

Common Applications in Industry

Copper busbars are widely used in electrical distribution systems, switchgear, and power panels due to their excellent conductivity and ability to handle high current loads efficiently. Copper rods are commonly employed in manufacturing fasteners, electrical wiring, and grounding applications, benefiting from their versatility and ease of fabrication. Both forms leverage copper's superior thermal and electrical properties, but busbars are preferred for structured electrical pathways, while rods are suited for components requiring precision and flexibility.

Cost Efficiency and Economic Considerations

Copper busbars generally offer higher cost efficiency than copper rods due to their enhanced conductivity and reduced resistance, which lowers energy losses in electrical systems. Economically, busbars require less installation time and maintenance, translating into long-term savings despite a higher upfront cost. Copper rods, while cheaper initially, may incur greater expenses over time because of higher energy losses and more frequent replacement needs.

Installation and Fabrication Differences

Copper busbars simplify installation due to their flat, rigid structure, allowing easy mounting and connection in electrical panels without extensive shaping. Copper rods require additional bending and cutting, increasing fabrication time and labor in complex electrical setups. The busbar's prefab form reduces installation errors, while rods offer more flexibility but demand precise manual fabrication.

Performance Under High Current Loads

Copper busbars exhibit superior performance under high current loads due to their larger surface area, which enhances heat dissipation and reduces resistance compared to copper rods. The flat, wide shape of busbars minimizes voltage drop and energy loss, making them more efficient for power distribution in industrial applications. Copper rods, while easier to install in confined spaces, typically face higher thermal buildup and resistive losses, limiting their effectiveness in high-current scenarios.

Choosing the Right Option: Busbar or Rod

Copper busbars provide superior current-carrying capacity and optimal heat dissipation in electrical distribution systems, making them ideal for high-load applications and compact installations. Copper rods offer versatility and ease of customization for grounding, electrical connections, and manufacturing processes where intricate shapes are required. Selecting between copper busbars and rods depends on specific project needs such as current requirements, installation space constraints, and mechanical strength.

Copper Busbar vs Copper Rod Infographic

materialdif.com

materialdif.com