Copper foil offers superior flexibility and thinness, making it ideal for delicate electronic applications and precision soldering. Copper strips provide greater strength and rigidity, suitable for structural support and electrical connections requiring sturdiness. Choosing between copper foil and copper strip depends on the specific needs of conductivity, flexibility, and mechanical durability in your copper pet project.

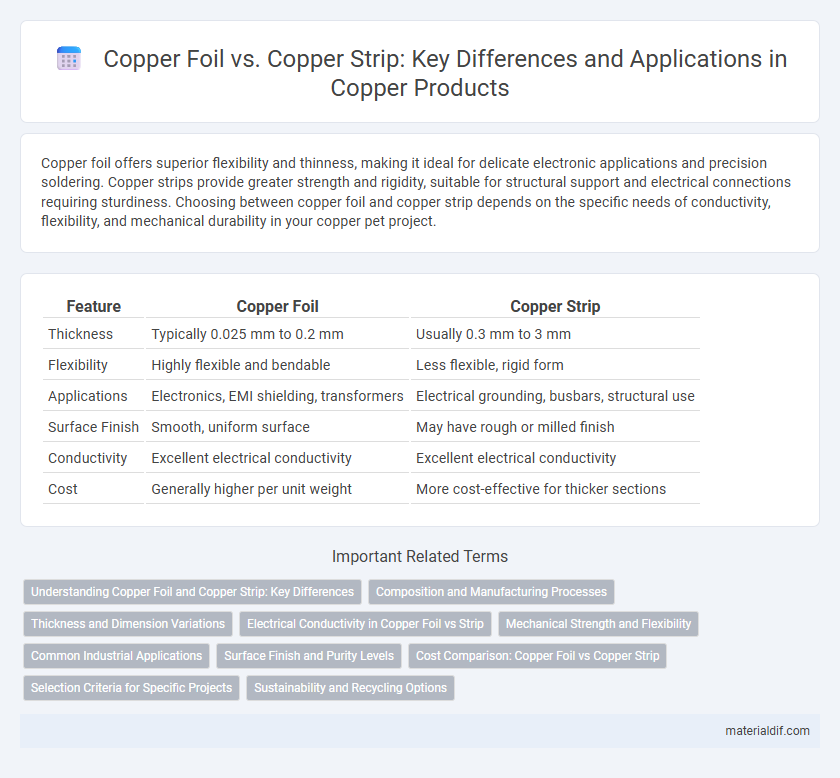

Table of Comparison

| Feature | Copper Foil | Copper Strip |

|---|---|---|

| Thickness | Typically 0.025 mm to 0.2 mm | Usually 0.3 mm to 3 mm |

| Flexibility | Highly flexible and bendable | Less flexible, rigid form |

| Applications | Electronics, EMI shielding, transformers | Electrical grounding, busbars, structural use |

| Surface Finish | Smooth, uniform surface | May have rough or milled finish |

| Conductivity | Excellent electrical conductivity | Excellent electrical conductivity |

| Cost | Generally higher per unit weight | More cost-effective for thicker sections |

Understanding Copper Foil and Copper Strip: Key Differences

Copper foil is an ultra-thin material primarily used in electronics for its excellent conductivity and flexibility, enabling precise applications like printed circuit boards and electromagnetic shielding. Copper strip is thicker and more rigid, commonly employed in electrical fittings, grounding systems, and industrial manufacturing where durability and structural strength are essential. The key differences lie in thickness, flexibility, and specific use cases, with copper foil favored for delicate, high-precision tasks and copper strip suited for robust, load-bearing applications.

Composition and Manufacturing Processes

Copper foil typically consists of ultra-thin layers of high-purity copper (above 99.9% purity) produced through electrolysis, resulting in smooth, flexible sheets ideal for electronic applications. Copper strip, in contrast, is thicker and manufactured primarily by rolling processes from cast billets or slabs, offering higher mechanical strength and rigidity for structural uses. The distinct manufacturing techniques influence their microstructure and mechanical properties, with foil favoring conductivity and strip emphasizing durability and formability.

Thickness and Dimension Variations

Copper foil typically features thicknesses ranging from 9 to 100 microns, making it ideal for flexible electronics and shielding applications due to its extremely thin and uniform dimensions. Copper strips, on the other hand, usually have thicknesses between 0.1 mm to several millimeters, offering greater rigidity and strength suitable for structural and electrical components. The dimensional variation in copper foil is minimal to maintain flexibility, while copper strips accommodate wider width and thickness tolerances to support diverse industrial uses.

Electrical Conductivity in Copper Foil vs Strip

Copper foil exhibits higher electrical conductivity compared to copper strip due to its thin, flexible structure allowing better electron flow and reduced resistance. The thinness of copper foil minimizes skin effect in high-frequency applications, enhancing conductivity in circuits and electronic components. Copper strip, being thicker and more rigid, offers durability but slightly lower efficiency in electrical transmission relative to copper foil.

Mechanical Strength and Flexibility

Copper foil offers superior flexibility due to its thin, pliable structure, making it ideal for applications requiring bending and wrapping without breaking. In contrast, copper strips provide greater mechanical strength and rigidity, suitable for structural components and heavy-duty electrical connections. The choice between copper foil and strip depends on the balance needed between flexibility and tensile strength in specific engineering applications.

Common Industrial Applications

Copper foil is widely used in printed circuit boards (PCBs) and electromagnetic shielding due to its thin, flexible properties, enabling precise electronic applications. Copper strip, thicker and more rigid, is common in electrical connectors, busbars, and grounding systems where durability and high conductivity are essential. Both materials are integral to electrical engineering, automotive manufacturing, and renewable energy technologies, serving distinct yet complementary industrial functions.

Surface Finish and Purity Levels

Copper foil typically features a smoother surface finish with a thickness ranging from 0.001 to 0.15 mm, making it ideal for applications requiring precise conductivity and flexibility. Copper strips are thicker, usually between 0.2 to 3 mm, and possess a rougher surface finish suited for structural and electrical components where durability is essential. Purity levels for both materials often exceed 99.9%, but copper foil used in electronics may have higher purity and specialized coatings to enhance conductivity and corrosion resistance.

Cost Comparison: Copper Foil vs Copper Strip

Copper foil generally costs more than copper strip due to its thinner gauge and specialized manufacturing process that requires precise control over thickness and surface finish. Copper strips, being thicker and produced in larger quantities for industrial applications, benefit from economies of scale that reduce their unit cost. The price difference is influenced by factors such as material purity, rolling techniques, and market demand in electronics versus construction sectors.

Selection Criteria for Specific Projects

Copper foil offers superior flexibility and thinness, making it ideal for intricate electronics and printed circuit boards requiring high conductivity in compact spaces. Copper strip provides increased mechanical strength and thicker dimensions, better suited for grounding, electrical bus bars, and heavy-duty applications where durability and current load capacity are critical. Selection between copper foil and strip hinges on project-specific criteria such as thickness requirements, electrical conductivity, mechanical stability, and thermal management.

Sustainability and Recycling Options

Copper foil offers a thinner, more flexible material that is easier to recycle in electronic waste due to its high purity and minimal material loss, whereas copper strips, typically thicker and sturdier, have broader recycling applications in construction and manufacturing but may involve more energy-intensive processes. Both materials are highly recyclable, with copper retaining its properties indefinitely, making them sustainable choices; however, foil's lightweight nature often results in lower transportation emissions during recycling cycles. Choosing between copper foil and copper strip depends on the specific sustainability goals and the recycling infrastructure available for electronic versus industrial copper waste streams.

Copper Foil vs Copper Strip Infographic

materialdif.com

materialdif.com