Copper pipes offer superior durability and resistance to high temperatures, making them ideal for long-lasting plumbing systems, while PEX pipes provide flexibility and easier installation, reducing labor time and costs. Copper's natural antimicrobial properties enhance water quality by inhibiting bacterial growth, whereas PEX pipes are resistant to scale and chlorine degradation, extending their lifespan in various water conditions. Both materials serve well in residential plumbing, but the choice depends on budget, water quality, and installation complexity.

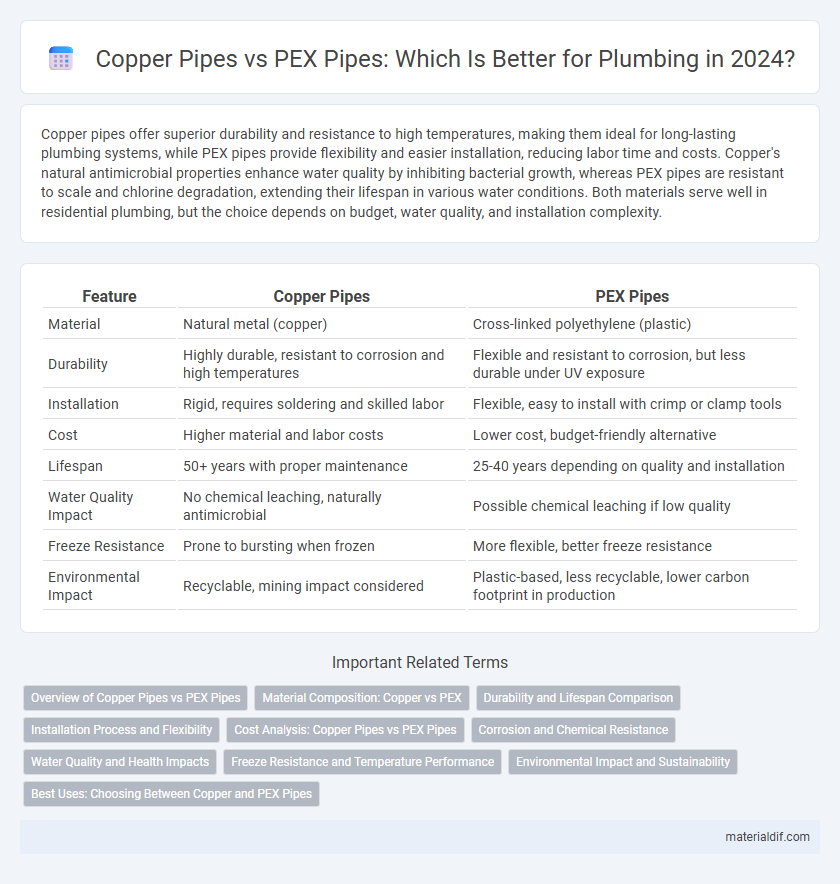

Table of Comparison

| Feature | Copper Pipes | PEX Pipes |

|---|---|---|

| Material | Natural metal (copper) | Cross-linked polyethylene (plastic) |

| Durability | Highly durable, resistant to corrosion and high temperatures | Flexible and resistant to corrosion, but less durable under UV exposure |

| Installation | Rigid, requires soldering and skilled labor | Flexible, easy to install with crimp or clamp tools |

| Cost | Higher material and labor costs | Lower cost, budget-friendly alternative |

| Lifespan | 50+ years with proper maintenance | 25-40 years depending on quality and installation |

| Water Quality Impact | No chemical leaching, naturally antimicrobial | Possible chemical leaching if low quality |

| Freeze Resistance | Prone to bursting when frozen | More flexible, better freeze resistance |

| Environmental Impact | Recyclable, mining impact considered | Plastic-based, less recyclable, lower carbon footprint in production |

Overview of Copper Pipes vs PEX Pipes

Copper pipes offer durability, fire resistance, and natural antimicrobial properties, making them a reliable choice for plumbing systems. PEX pipes provide flexibility, ease of installation, and resistance to scale and chlorine, often reducing labor costs and installation time. Both materials are widely used in residential and commercial applications, with selection depending on factors such as budget, local building codes, and specific plumbing needs.

Material Composition: Copper vs PEX

Copper pipes are composed of pure copper metal, offering high corrosion resistance, durability, and the ability to withstand extreme temperatures and pressures. PEX pipes are made from cross-linked polyethylene, a flexible plastic that resists scale buildup, chlorination, and freezing damage but has lower temperature tolerance compared to copper. The material composition directly impacts lifespan, installation methods, and suitability for hot and cold water systems in residential and commercial plumbing.

Durability and Lifespan Comparison

Copper pipes offer exceptional durability with a lifespan of 50 years or more, resisting corrosion and high temperatures effectively. PEX pipes, while flexible and resistant to scale and chlorine, generally have a shorter lifespan of about 25 to 40 years under optimal conditions. The choice between copper and PEX often depends on the specific application and environmental factors influencing longevity.

Installation Process and Flexibility

Copper pipes require soldering and specialized tools, making the installation process labor-intensive and time-consuming, while PEX pipes utilize push-fit or crimp fittings, significantly reducing installation time and effort. PEX offers superior flexibility, easily bending around corners and eliminating the need for multiple fittings, which contrasts with copper pipes that are rigid and often require additional joints or elbows. This flexibility in PEX not only simplifies installation but also enhances durability by resisting corrosion and stress fractures better than copper.

Cost Analysis: Copper Pipes vs PEX Pipes

Copper pipes typically cost between $2 to $4 per linear foot, making them more expensive upfront compared to PEX pipes, which range from $0.50 to $2 per linear foot. Installation costs for copper are higher due to the need for soldering and skilled labor, whereas PEX installation is faster and requires fewer specialized tools, reducing labor expenses. Over time, PEX pipes offer better cost efficiency in both materials and labor, making them a more budget-friendly choice for plumbing projects.

Corrosion and Chemical Resistance

Copper pipes exhibit excellent corrosion resistance in most water conditions, maintaining durability and preventing contamination over time, whereas PEX pipes are inherently resistant to corrosion because they are made from flexible polyethylene, which does not react with water or chemicals. Chemical resistance in PEX pipes surpasses copper pipes, especially against acidic or alkaline water, as copper can corrode when exposed to certain aggressive chemicals or water chemistries. The choice between copper and PEX pipes depends on water chemistry and the presence of corrosive agents, with PEX offering superior longevity in environments prone to chemical exposure.

Water Quality and Health Impacts

Copper pipes naturally inhibit bacterial growth due to their antimicrobial properties, ensuring improved water quality and reducing health risks associated with pathogens. PEX pipes, while resistant to scale and chlorine, may leach small amounts of chemicals, which can affect taste and potentially impact long-term water safety. Studies indicate copper's durability and ability to maintain water purity often make it a preferred choice for health-conscious plumbing systems.

Freeze Resistance and Temperature Performance

Copper pipes exhibit superior freeze resistance due to their rigidity and thermal conductivity, enabling them to withstand temperature fluctuations without cracking. PEX pipes offer greater flexibility, allowing expansion during freezing conditions, which reduces the risk of bursting but may degrade faster under prolonged high temperatures above 200degF (93degC). Copper maintains consistent performance across a wider temperature range of -40degF to 400degF (-40degC to 204degC), making it ideal for extreme climates and hot water applications.

Environmental Impact and Sustainability

Copper pipes are highly durable and recyclable, reducing long-term environmental waste, but their mining and extraction processes consume significant energy and contribute to habitat disruption. PEX pipes are made from plastic polymers, requiring less energy to produce and offering lower greenhouse gas emissions during manufacturing, yet they pose challenges in recyclability and potential microplastic pollution. Considering overall sustainability, copper's natural recyclability contrasts with PEX's lower production footprint but limited end-of-life recovery options.

Best Uses: Choosing Between Copper and PEX Pipes

Copper pipes offer exceptional durability and heat resistance, making them ideal for hot water supply lines and outdoor applications where exposure to sunlight is a concern. PEX pipes provide flexibility, corrosion resistance, and easier installation, which suits them best for indoor plumbing, radiant heating systems, and retrofit projects. Selecting between copper and PEX depends on factors like budget, climate, water quality, and the specific plumbing requirements of the building.

Copper Pipes vs PEX Pipes Infographic

materialdif.com

materialdif.com