Rolled copper offers enhanced strength and flexibility due to its uniform grain structure, making it ideal for electrical wiring and roofing applications. Cast copper, created by pouring molten metal into molds, provides intricate shapes and is often used in artistic sculptures and industrial components. The choice between rolled and cast copper depends on whether precision and durability or complex design and form are prioritized.

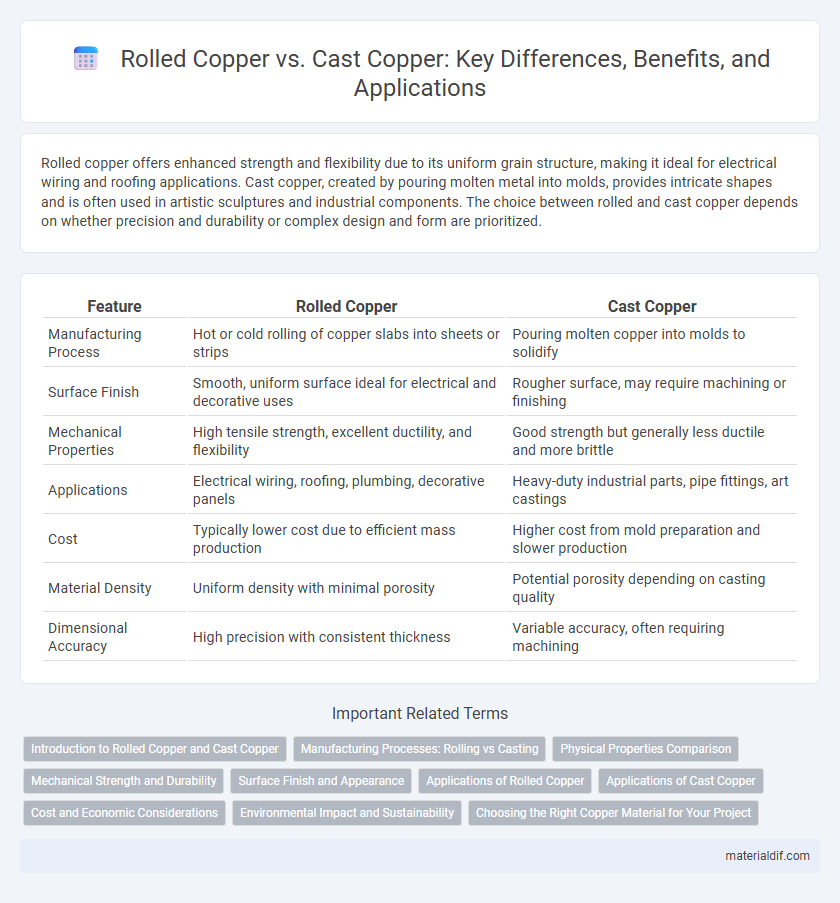

Table of Comparison

| Feature | Rolled Copper | Cast Copper |

|---|---|---|

| Manufacturing Process | Hot or cold rolling of copper slabs into sheets or strips | Pouring molten copper into molds to solidify |

| Surface Finish | Smooth, uniform surface ideal for electrical and decorative uses | Rougher surface, may require machining or finishing |

| Mechanical Properties | High tensile strength, excellent ductility, and flexibility | Good strength but generally less ductile and more brittle |

| Applications | Electrical wiring, roofing, plumbing, decorative panels | Heavy-duty industrial parts, pipe fittings, art castings |

| Cost | Typically lower cost due to efficient mass production | Higher cost from mold preparation and slower production |

| Material Density | Uniform density with minimal porosity | Potential porosity depending on casting quality |

| Dimensional Accuracy | High precision with consistent thickness | Variable accuracy, often requiring machining |

Introduction to Rolled Copper and Cast Copper

Rolled copper is produced by passing copper through rollers to achieve thin, uniform sheets or strips ideal for electrical wiring and roofing. Cast copper forms when molten copper is poured into molds to create solid shapes like ingots or large blocks used in heavy-duty applications. Both processes influence copper's mechanical properties and determine its suitability for specific industrial uses.

Manufacturing Processes: Rolling vs Casting

Rolled copper is produced through a hot rolling or cold rolling process where copper slabs are passed through rollers to achieve uniform thickness and enhanced mechanical properties. Cast copper is made by melting copper and pouring it into molds to solidify, which allows for complex shapes but may result in less uniform microstructure. Rolling refines grain structure and improves ductility, whereas casting offers design flexibility but may require further machining for precision.

Physical Properties Comparison

Rolled copper exhibits superior tensile strength and ductility compared to cast copper due to its refined grain structure achieved through mechanical deformation processes. Cast copper tends to have a coarser grain structure, resulting in lower strength and increased brittleness, but it often provides better dimensional accuracy and is suitable for complex shapes. The density of both forms remains similar around 8.96 g/cm3, while thermal and electrical conductivities are generally higher in rolled copper due to less porosity and fewer impurities.

Mechanical Strength and Durability

Rolled copper exhibits higher mechanical strength and enhanced durability compared to cast copper due to its refined grain structure formed during the rolling process. The cold working and deformation in rolled copper increase dislocation density, resulting in improved tensile strength and resistance to wear. Cast copper, while easier to shape into complex forms, tends to have coarser grains and potential porosity, which can reduce its mechanical strength and long-term durability.

Surface Finish and Appearance

Rolled copper features a smooth, uniform surface finish achieved through mechanical rolling that enhances its aesthetic appeal and is ideal for decorative applications. Cast copper has a rougher, less uniform appearance due to the solidification process, often requiring additional machining or polishing to improve surface quality. The choice between rolled and cast copper depends on the desired surface smoothness and visual consistency for specific uses.

Applications of Rolled Copper

Rolled copper is extensively used in electrical applications due to its excellent electrical conductivity and flexibility, making it ideal for wiring, busbars, and transformers. Its uniform thickness and smooth surface facilitate efficient heat dissipation in heat exchangers and radiators. Rolled copper also serves critical roles in roofing and cladding, providing corrosion resistance and aesthetic appeal in architectural projects.

Applications of Cast Copper

Cast copper offers superior strength and corrosion resistance, making it ideal for heavy-duty industrial applications such as pump and valve components, marine hardware, and electrical connectors. Its ability to form complex shapes with precise dimensions ensures optimal performance in aerospace and automotive parts exposed to high stress and heat. Cast copper alloys are also preferred in construction for durable fittings and architectural elements due to their excellent wear resistance and longevity.

Cost and Economic Considerations

Rolled copper typically incurs higher production costs due to advanced machinery and energy-intensive processes but offers superior mechanical properties and precision, making it ideal for high-performance applications. Cast copper features lower initial manufacturing expenses because of simpler mold-based shaping but often requires further machining, increasing total processing costs and impacting economic efficiency in long-term use. Evaluating project requirements and volume is crucial, as rolled copper provides better value for high-demand, quality-sensitive industries, while cast copper suits budget-conscious, low-volume productions.

Environmental Impact and Sustainability

Rolled copper production generally consumes less energy and generates lower carbon emissions compared to cast copper due to fewer processing steps and reduced waste. Cast copper often involves higher melting temperatures, leading to increased fuel consumption and greater environmental impact. Selecting rolled copper supports sustainability by minimizing resource depletion and enhancing recyclability through more efficient manufacturing processes.

Choosing the Right Copper Material for Your Project

Rolled copper offers superior strength, uniformity, and precision, making it ideal for applications requiring consistent thickness and enhanced mechanical properties. Cast copper provides greater design flexibility and complex shapes due to its molten form, suitable for decorative or intricate projects where structural uniformity is less critical. Selecting between rolled and cast copper depends on project requirements such as durability, design complexity, and mechanical performance.

Rolled Copper vs Cast Copper Infographic

materialdif.com

materialdif.com