Copper exhibits superior electrical conductivity and corrosion resistance compared to lead, making it a preferred choice for electrical wiring and plumbing applications. Unlike lead, copper is non-toxic and environmentally safer, reducing health risks associated with lead exposure. Its higher strength and ductility also enhance durability in industrial uses where lead would be prone to deformation and deterioration.

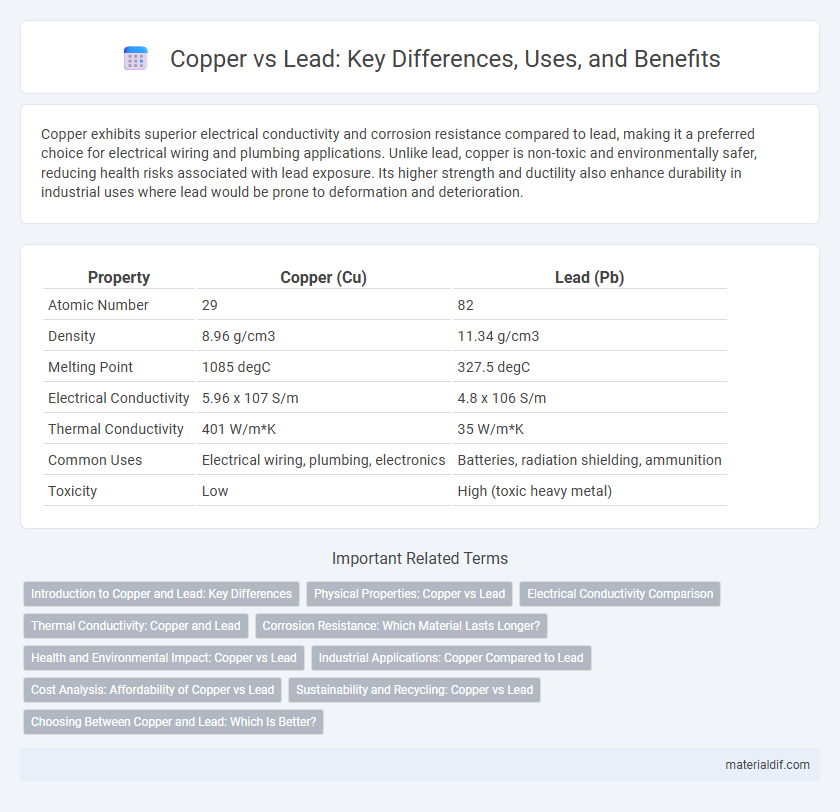

Table of Comparison

| Property | Copper (Cu) | Lead (Pb) |

|---|---|---|

| Atomic Number | 29 | 82 |

| Density | 8.96 g/cm3 | 11.34 g/cm3 |

| Melting Point | 1085 degC | 327.5 degC |

| Electrical Conductivity | 5.96 x 107 S/m | 4.8 x 106 S/m |

| Thermal Conductivity | 401 W/m*K | 35 W/m*K |

| Common Uses | Electrical wiring, plumbing, electronics | Batteries, radiation shielding, ammunition |

| Toxicity | Low | High (toxic heavy metal) |

Introduction to Copper and Lead: Key Differences

Copper is a highly conductive metal known for its exceptional electrical and thermal conductivity, corrosion resistance, and malleability, making it vital in electrical wiring, plumbing, and industrial machinery. Lead, a denser and softer metal, is characterized by its high resistance to corrosion and low melting point, often used in batteries, radiation shielding, and soldering applications. The key differences between copper and lead include conductivity, with copper excelling in electrical applications, and toxicity, as lead poses significant health risks while copper is generally safer for use in consumer products.

Physical Properties: Copper vs Lead

Copper exhibits higher thermal and electrical conductivity compared to lead, making it superior for electrical applications. With a density of approximately 8.96 g/cm3, copper is less dense than lead, which has a density of about 11.34 g/cm3, resulting in copper being lighter and more durable for structural use. Copper's melting point is significantly higher at 1085degC, while lead melts at 327.5degC, influencing their suitability for various high-temperature applications.

Electrical Conductivity Comparison

Copper exhibits significantly higher electrical conductivity than lead, with copper's conductivity at approximately 5.96 x 10^7 S/m compared to lead's much lower value around 4.8 x 10^6 S/m. This makes copper the preferred material for electrical wiring and components due to its efficient electron flow and minimal resistive losses. Lead's poor conductivity limits its use in electrical applications, favoring its role in shielding and battery components instead.

Thermal Conductivity: Copper and Lead

Copper exhibits significantly higher thermal conductivity than lead, with copper's thermal conductivity around 400 W/m*K compared to lead's approximately 35 W/m*K. This makes copper far more efficient in heat transfer applications, frequently utilized in electrical wiring and heat exchangers. Lead's low thermal conductivity limits its use to applications needing thermal insulation or weight rather than heat dissipation.

Corrosion Resistance: Which Material Lasts Longer?

Copper exhibits superior corrosion resistance compared to lead, making it more durable in diverse environmental conditions such as exposure to water, air, and soil. Copper forms a protective oxide layer that prevents further degradation, while lead is more prone to oxidation and corrosion over time. This enhanced corrosion resistance of copper results in a longer lifespan for applications like plumbing, marine environments, and electrical components.

Health and Environmental Impact: Copper vs Lead

Copper exhibits significantly lower toxicity compared to lead, reducing health risks such as neurotoxicity and developmental impairments commonly associated with lead exposure. Environmentally, copper is less persistent and bioaccumulative, posing a smaller threat to soil and water quality, whereas lead contamination often results in long-lasting ecological damage and impaired biodiversity. Copper's essential role as a trace element in human nutrition also contrasts sharply with lead's status as a non-essential, hazardous poison.

Industrial Applications: Copper Compared to Lead

Copper exhibits superior electrical conductivity and corrosion resistance compared to lead, making it the preferred choice in electrical wiring and electronic components manufacturing. Its non-toxic nature enables extensive use in plumbing and potable water systems, whereas lead's toxicity limits its application due to health concerns. Industrial sectors favor copper for heat exchangers and renewable energy systems, benefiting from its thermal efficiency and environmental safety advantages over lead.

Cost Analysis: Affordability of Copper vs Lead

Copper is generally more expensive than lead due to its higher conductivity, durability, and widespread industrial demand, making it a costlier investment upfront. Lead's affordability stems from lower raw material and processing costs, but it offers inferior mechanical and corrosion resistance compared to copper. When evaluating long-term value, copper's higher initial cost can be offset by lower maintenance and replacement expenses, enhancing overall cost-effectiveness.

Sustainability and Recycling: Copper vs Lead

Copper offers superior sustainability compared to lead due to its high recyclability and lower environmental toxicity. Copper can be recycled repeatedly without loss of quality, reducing the demand for mining and lowering greenhouse gas emissions. In contrast, lead recycling poses health hazards due to its toxicity and often requires stringent environmental controls.

Choosing Between Copper and Lead: Which Is Better?

Copper offers superior corrosion resistance, higher electrical conductivity, and is more environmentally friendly compared to lead. Lead, while denser and easier to mold, poses significant health risks due to its toxicity and has been largely phased out in plumbing and electrical applications. Choosing copper over lead ensures enhanced durability, safety, and compliance with modern regulations.

Copper vs Lead Infographic

materialdif.com

materialdif.com