Soft copper offers excellent flexibility and is ideal for applications requiring bending and shaping, making it perfect for plumbing and HVAC systems. Rigid copper, on the other hand, provides superior strength and durability, commonly used in structural piping and long-term installations. Choosing between soft and rigid copper depends on the specific needs of the project, balancing flexibility with strength.

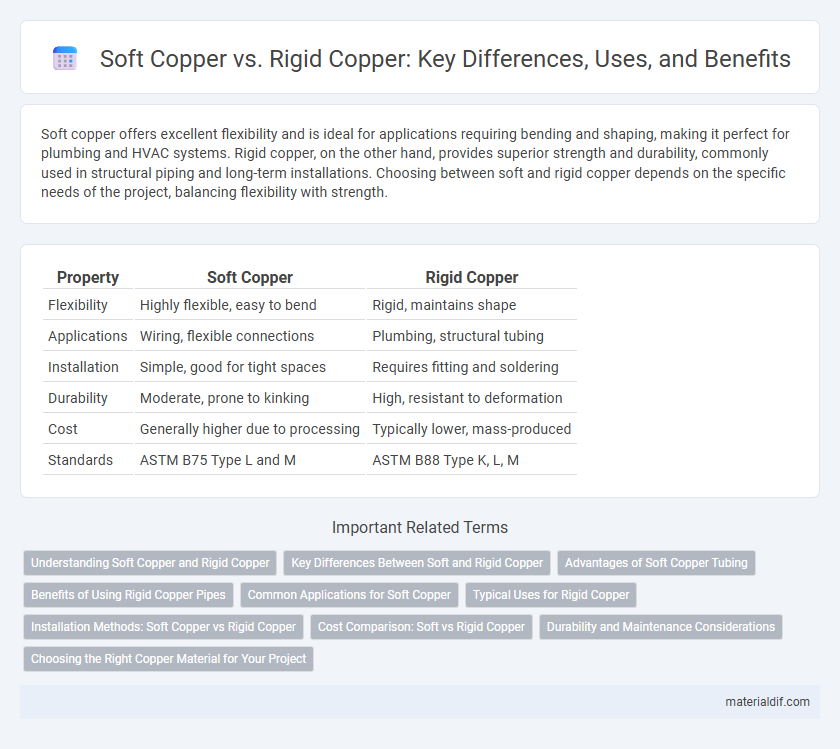

Table of Comparison

| Property | Soft Copper | Rigid Copper |

|---|---|---|

| Flexibility | Highly flexible, easy to bend | Rigid, maintains shape |

| Applications | Wiring, flexible connections | Plumbing, structural tubing |

| Installation | Simple, good for tight spaces | Requires fitting and soldering |

| Durability | Moderate, prone to kinking | High, resistant to deformation |

| Cost | Generally higher due to processing | Typically lower, mass-produced |

| Standards | ASTM B75 Type L and M | ASTM B88 Type K, L, M |

Understanding Soft Copper and Rigid Copper

Soft copper offers exceptional flexibility and malleability, making it ideal for applications requiring bending and shaping without breaking. Rigid copper, characterized by its hardness and strength, provides stability and durability for structural electrical wiring and plumbing systems. Proper selection between soft and rigid copper depends on project requirements for flexibility versus strength and long-term reliability.

Key Differences Between Soft and Rigid Copper

Soft copper features high malleability allowing easy bending and shaping, ideal for plumbing and flexible conduit applications. Rigid copper offers superior strength and durability, making it suitable for structural uses and long-lasting piping systems. The key differences lie in flexibility, installation methods, and resistance to physical stress.

Advantages of Soft Copper Tubing

Soft copper tubing offers superior flexibility and ease of installation in tight or complex spaces, reducing the need for fittings and minimizing potential leak points. Its malleability allows for bending without kinking, making it ideal for residential and commercial plumbing systems where intricate routing is required. Soft copper also absorbs vibrations and thermal expansion better, enhancing system durability and longevity.

Benefits of Using Rigid Copper Pipes

Rigid copper pipes offer superior durability and strength, making them ideal for high-pressure water and gas systems. Their corrosion resistance and long lifespan reduce maintenance costs and potential leaks, enhancing system reliability. These pipes also provide a solid structure that resists deformation, ensuring secure connections and optimal flow efficiency in plumbing installations.

Common Applications for Soft Copper

Soft copper is commonly used in plumbing systems, HVAC refrigeration lines, and flexible electrical wiring due to its excellent malleability and ease of bending. Its ability to withstand repeated flexing without breaking makes it ideal for applications requiring frequent movement or vibration absorption. Soft copper also finds use in craft and decorative projects where shaping and forming are essential.

Typical Uses for Rigid Copper

Rigid copper is commonly used in plumbing systems, providing durable and corrosion-resistant piping for both residential and commercial water supply lines. It is also extensively utilized in HVAC applications for refrigerant lines due to its strength and ability to withstand high pressure. Electrical wiring and grounding systems benefit from rigid copper's excellent conductivity and structural stability.

Installation Methods: Soft Copper vs Rigid Copper

Soft copper offers flexibility that simplifies installation in tight spaces and complex bends without the need for additional fittings, making it ideal for residential and HVAC applications. Rigid copper requires precise measurements and soldering but provides durable, secure joints often used in water supply lines and exposed piping systems. Installation of soft copper typically involves flaring or compression fittings, while rigid copper relies heavily on sweat (soldered) connections for robust sealing.

Cost Comparison: Soft vs Rigid Copper

Soft copper typically incurs higher costs due to increased manufacturing complexity and material flexibility, which enhances its suitability for intricate plumbing and electrical applications. Rigid copper generally offers a lower price point, benefiting from simpler production processes and reduced material usage, making it ideal for straightforward installations. Evaluating project requirements against budget constraints is essential to determine the most cost-effective choice between soft and rigid copper.

Durability and Maintenance Considerations

Soft copper offers greater flexibility, making it less prone to cracking under stress but more susceptible to dents and deformation over time. Rigid copper provides superior durability with higher resistance to physical damage and corrosion, resulting in a longer lifespan and lower maintenance requirements. Maintenance for soft copper often involves regular inspection for physical damage and potential leaks, whereas rigid copper demands less frequent maintenance due to its robust structure.

Choosing the Right Copper Material for Your Project

Soft copper, known for its flexibility and ease of bending, is ideal for projects requiring intricate shapes or tight spaces, such as plumbing and HVAC systems. Rigid copper offers superior strength and durability, making it suitable for structural applications and long-term installations in electrical wiring or construction. Selecting the right copper material depends on project requirements, budget constraints, and environmental factors to ensure optimal performance and longevity.

Soft Copper vs Rigid Copper Infographic

materialdif.com

materialdif.com