C101 and C110 copper are both high-purity copper grades primarily utilized in electrical and thermal applications due to their excellent conductivity. C101 copper contains at least 99.99% purity, making it slightly purer than C110 copper, which has a minimum purity of 99.9%. The higher purity of C101 copper results in superior electrical and thermal conductivity, making it preferable for critical electronic components and high-performance electrical wiring.

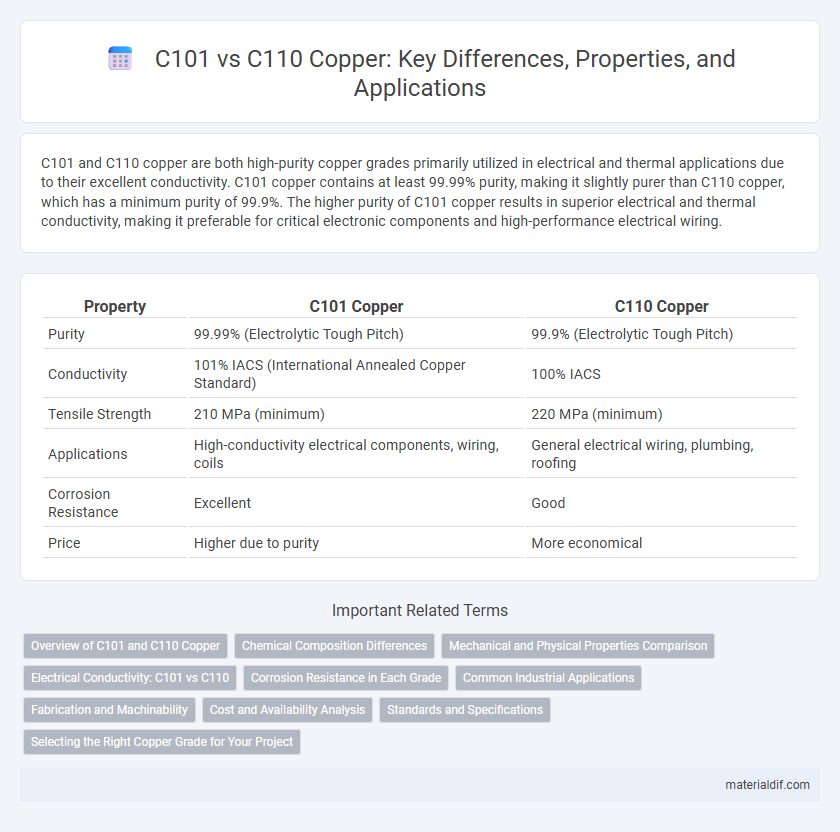

Table of Comparison

| Property | C101 Copper | C110 Copper |

|---|---|---|

| Purity | 99.99% (Electrolytic Tough Pitch) | 99.9% (Electrolytic Tough Pitch) |

| Conductivity | 101% IACS (International Annealed Copper Standard) | 100% IACS |

| Tensile Strength | 210 MPa (minimum) | 220 MPa (minimum) |

| Applications | High-conductivity electrical components, wiring, coils | General electrical wiring, plumbing, roofing |

| Corrosion Resistance | Excellent | Good |

| Price | Higher due to purity | More economical |

Overview of C101 and C110 Copper

C101 copper, also known as Electrolytic Tough Pitch (ETP) copper, contains a minimum of 99.9% purity with a small oxygen content, making it highly conductive and suitable for electrical applications. C110 copper offers slightly higher purity, typically 99.99%, and lower oxygen levels, enhancing its ductility and corrosion resistance for applications such as plumbing and roofing. Both grades exhibit excellent electrical and thermal conductivity, but C110's superior purity makes it ideal for more demanding industrial environments.

Chemical Composition Differences

C101 copper contains a minimum of 99.99% pure copper, with trace amounts of oxygen and other impurities, while C110 copper, also known as Electrolytic Tough Pitch (ETP) copper, typically contains 99.9% copper with a controlled oxygen content around 0.02-0.04%. The higher purity in C101 results in superior electrical conductivity and corrosion resistance compared to C110. Oxygen content in C110 improves machinability but can cause oxidation during processing, distinguishing its chemical and physical properties from C101 copper.

Mechanical and Physical Properties Comparison

C101 copper offers higher purity with a minimum of 99.99% copper content, resulting in superior electrical and thermal conductivity compared to C110, which typically contains 99.9% copper. Mechanically, C101 exhibits better tensile strength and elongation, making it more suitable for applications demanding exceptional ductility and high conductivity. Physically, both grades have similar density and melting points, but C101's enhanced purity improves corrosion resistance and performance in critical electronic and industrial components.

Electrical Conductivity: C101 vs C110

C101 copper exhibits the highest electrical conductivity available in copper alloys, typically reaching about 101% IACS (International Annealed Copper Standard), making it ideal for precision electrical components. C110 copper, known as electrolytic tough pitch (ETP) copper, offers slightly lower conductivity at approximately 100% IACS but balances excellent electrical performance with cost-effectiveness. Both grades maintain superior conductivity for electrical applications, with C101 favored where maximum conductivity is critical and C110 widely used in general electrical wiring and industrial applications.

Corrosion Resistance in Each Grade

C101 copper, composed of 99.99% pure copper, exhibits superior corrosion resistance compared to C110 copper, which contains up to 99.9% purity with slight trace impurities. The high purity in C101 minimizes the presence of foreign elements that can initiate corrosion, making it ideal for applications in highly corrosive environments like chemical processing and marine uses. In contrast, C110's marginally lower purity still offers excellent corrosion resistance but is better suited for general electrical and structural applications where extreme corrosion resistance is less critical.

Common Industrial Applications

C101 copper, also known as oxygen-free high conductivity (OFHC) copper, offers superior electrical conductivity and corrosion resistance, making it ideal for high-end electrical connectors, semiconductor manufacturing, and vacuum equipment. C110 copper, or electrolytic tough pitch (ETP) copper, provides excellent electrical and thermal conductivity at a lower cost, commonly used in electrical wiring, busbars, and roofing materials. Both grades are widely applied in electrical and thermal systems, with C101 preferred for precision applications requiring ultra-pure copper and C110 favored for general industrial use due to its balance of performance and affordability.

Fabrication and Machinability

C101 copper, with its ultra-high purity of 99.99%, offers superior electrical conductivity but poses challenges in machining due to its softness and tendency to gum tooling. In contrast, C110 copper, slightly less pure at 99.9%, balances excellent electrical conductivity with enhanced machinability and ease of fabrication, making it a preferred choice for components requiring complex shaping. Fabrication processes such as bending, forming, and machining benefit from C110's improved strength and reduced tool wear, while C101 is often selected for applications prioritizing maximum conductivity over machinability.

Cost and Availability Analysis

C101 copper, also known as Oxygen-Free High Conductivity (OFHC) copper, offers superior electrical conductivity and corrosion resistance compared to C110, making it ideal for high-performance electrical applications but comes at a higher cost due to its purity and refining process. C110 copper, often referred to as Electrolytic Tough Pitch (ETP) copper, is more widely available and cost-effective, commonly used in general electrical and industrial components where ultra-high conductivity is not critical. Market trends indicate that while C101 commands a premium price, its availability is limited to specialty suppliers, whereas C110 benefits from robust supply chains and lower material costs, influencing procurement decisions based on budget and performance needs.

Standards and Specifications

C101 copper, known as oxygen-free electronic (OFE) copper, adheres to ASTM B187 and CDA C10100 standards, offering a minimum copper purity of 99.99% with reduced oxygen content for superior electrical conductivity and corrosion resistance. C110 copper, often termed electrolytic tough pitch (ETP) copper, meets ASTM B152 and CDA C11000 standards, featuring a slightly lower purity of about 99.9% and a controlled oxygen content, making it widely used for electrical wiring and tubing due to its excellent balance of conductivity and mechanical strength. Both alloys conform to industry specifications ensuring reliability in electrical and industrial applications, with C101 favored for high-performance electronic components and C110 commonly utilized in general electrical infrastructure.

Selecting the Right Copper Grade for Your Project

C101 copper offers superior purity with a minimum of 99.99% copper content, making it ideal for electrical applications requiring high conductivity and corrosion resistance. C110 copper, containing approximately 99.9% copper, provides excellent formability and is widely used in plumbing and general manufacturing. Selecting the right copper grade depends on balancing electrical performance needs with mechanical properties and cost efficiency for your specific project requirements.

C101 vs C110 Copper Infographic

materialdif.com

materialdif.com