Deoxidized copper contains additives that remove oxygen during melting, resulting in improved electrical conductivity and reduced porosity compared to non-deoxidized copper. Non-deoxidized copper retains oxygen, which can cause internal oxidation and lead to inferior mechanical properties and reduced corrosion resistance. Choosing deoxidized copper is essential for applications requiring high purity, reliability, and enhanced performance in electrical and industrial components.

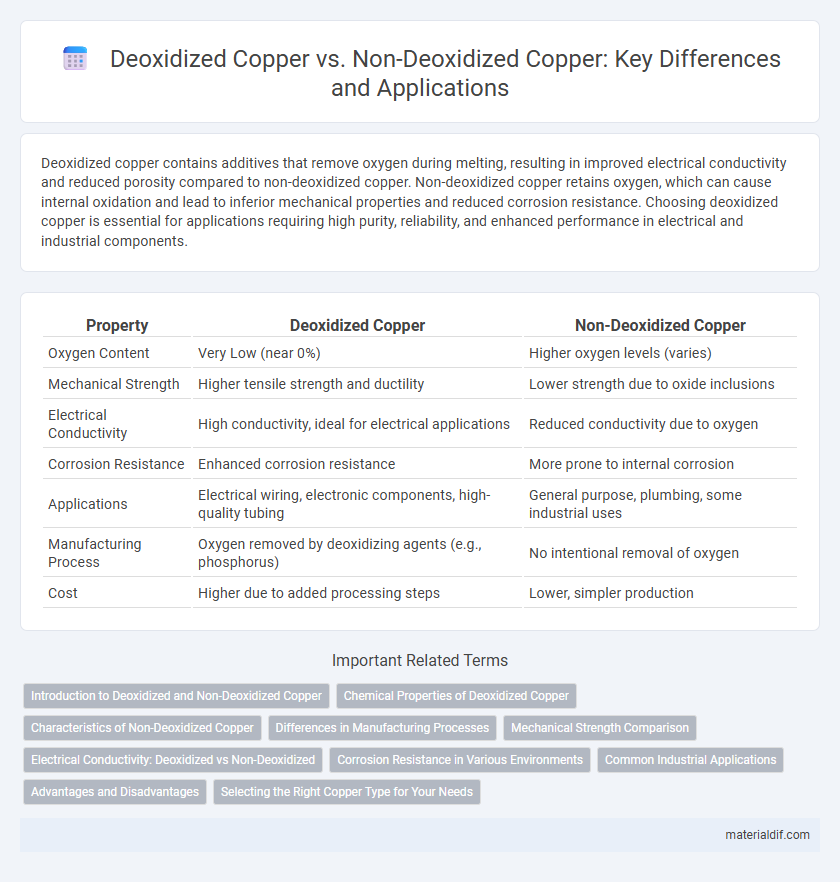

Table of Comparison

| Property | Deoxidized Copper | Non-Deoxidized Copper |

|---|---|---|

| Oxygen Content | Very Low (near 0%) | Higher oxygen levels (varies) |

| Mechanical Strength | Higher tensile strength and ductility | Lower strength due to oxide inclusions |

| Electrical Conductivity | High conductivity, ideal for electrical applications | Reduced conductivity due to oxygen |

| Corrosion Resistance | Enhanced corrosion resistance | More prone to internal corrosion |

| Applications | Electrical wiring, electronic components, high-quality tubing | General purpose, plumbing, some industrial uses |

| Manufacturing Process | Oxygen removed by deoxidizing agents (e.g., phosphorus) | No intentional removal of oxygen |

| Cost | Higher due to added processing steps | Lower, simpler production |

Introduction to Deoxidized and Non-Deoxidized Copper

Deoxidized copper, also known as tough pitch copper, contains oxygen removed through adding deoxidizers like phosphorus or oxygen scavengers during the smelting process, enhancing its electrical conductivity and mechanical strength. Non-deoxidized copper retains its natural oxygen content, resulting in higher porosity and reduced conductivity, making it less suitable for high-performance electrical applications. The choice between deoxidized and non-deoxidized copper depends on specific industrial requirements, such as conductivity, machinability, and resistance to oxidation.

Chemical Properties of Deoxidized Copper

Deoxidized copper contains added elements such as phosphorus, silicon, or aluminum, which chemically bind with oxygen to minimize oxide inclusions, resulting in improved electrical conductivity and corrosion resistance compared to non-deoxidized copper. This process enhances the metal's purity and structural homogeneity by eliminating oxygen-related defects that typically cause brittleness and reduced ductility in non-deoxidized copper. The chemical stability of deoxidized copper makes it ideal for applications requiring high thermal and electrical performance combined with long-term durability.

Characteristics of Non-Deoxidized Copper

Non-deoxidized copper, also known as oxygenized copper, contains dissolved oxygen, which enhances its ductility and weldability but reduces electrical conductivity compared to deoxidized copper. It is typically used in applications where high electrical performance is less critical, such as roofing and architectural components. The presence of oxygen improves its resistance to hydrogen embrittlement, making it suitable for certain brazing processes.

Differences in Manufacturing Processes

Deoxidized copper undergoes a manufacturing process where oxygen is removed by adding deoxidizing agents like phosphorus or silicon during melting, ensuring improved conductivity and reduced porosity. Non-deoxidized copper is produced without these agents, resulting in higher oxygen content, which can cause microscopic bubbles and reduced mechanical strength. The differing processes impact the copper's purity, structural integrity, and suitability for electrical and industrial applications.

Mechanical Strength Comparison

Deoxidized copper exhibits higher mechanical strength due to reduced oxygen levels, which minimize the formation of brittle copper oxide inclusions that weaken the metal. In contrast, non-deoxidized copper contains oxygen that forms copper oxide inclusions during solidification, leading to decreased tensile strength and ductility. This difference makes deoxidized copper more suitable for applications requiring superior mechanical performance and reliability.

Electrical Conductivity: Deoxidized vs Non-Deoxidized

Deoxidized copper exhibits higher electrical conductivity compared to non-deoxidized copper due to the removal of oxygen, which minimizes oxide inclusions that impede electron flow. The presence of oxygen in non-deoxidized copper forms copper oxides, increasing electrical resistance and reducing overall conductivity. For applications requiring superior electrical performance, deoxidized copper is preferred to ensure minimal resistive losses.

Corrosion Resistance in Various Environments

Deoxidized copper exhibits superior corrosion resistance in aggressive environments due to the removal of oxygen, which minimizes internal oxidation and enhances durability in acidic and marine conditions. Non-deoxidized copper, containing residual oxygen, is more prone to internal corrosion and stress cracking, especially in humid or polluted atmospheres. This distinction makes deoxidized copper the preferred choice for applications requiring long-term stability and resistance to corrosive agents.

Common Industrial Applications

Deoxidized copper, known for its improved conductivity and reduced gas porosity, is widely used in electrical wiring, electronic components, and high-performance connectors where reliability is critical. Non-deoxidized copper, which may contain oxygen, is often applied in plumbing, roofing, and general industrial manufacturing where ductility and ease of fabrication are prioritized over electrical properties. The choice between deoxidized and non-deoxidized copper depends on the specific industrial requirements for electrical conductivity, mechanical strength, and corrosion resistance.

Advantages and Disadvantages

Deoxidized copper, which contains low oxygen levels due to the addition of deoxidizing agents like phosphorus or silicon during processing, offers superior conductivity and improved corrosion resistance, making it ideal for electrical applications where performance and durability are critical. Non-deoxidized copper retains higher oxygen content, which can cause porosity and reduce ductility, but it is less expensive and easier to form, suitable for general plumbing and decorative uses. The trade-off lies in the enhanced mechanical properties and reliability of deoxidized copper versus the cost-effectiveness and workability of non-deoxidized copper.

Selecting the Right Copper Type for Your Needs

Choosing between deoxidized copper and non-deoxidized copper depends on your specific application requirements and environmental conditions. Deoxidized copper, treated to remove oxygen content, offers superior electrical conductivity and enhanced corrosion resistance, making it ideal for high-performance electrical components and marine applications. Non-deoxidized copper, containing more oxygen, is generally more cost-effective and suitable for general plumbing and decorative purposes where extreme conductivity or corrosion resistance is not critical.

Deoxidized Copper vs Non-Deoxidized Copper Infographic

materialdif.com

materialdif.com