Copper coils are primarily used in electromagnetic applications due to their ability to generate magnetic fields when an electric current passes through them, making them essential in motors, transformers, and inductors. Copper cables, on the other hand, are designed for efficient electrical power transmission and communication signals, offering high conductivity and flexibility for various wiring applications. The choice between copper coil and copper cable depends on the specific electrical function and physical configuration required.

Table of Comparison

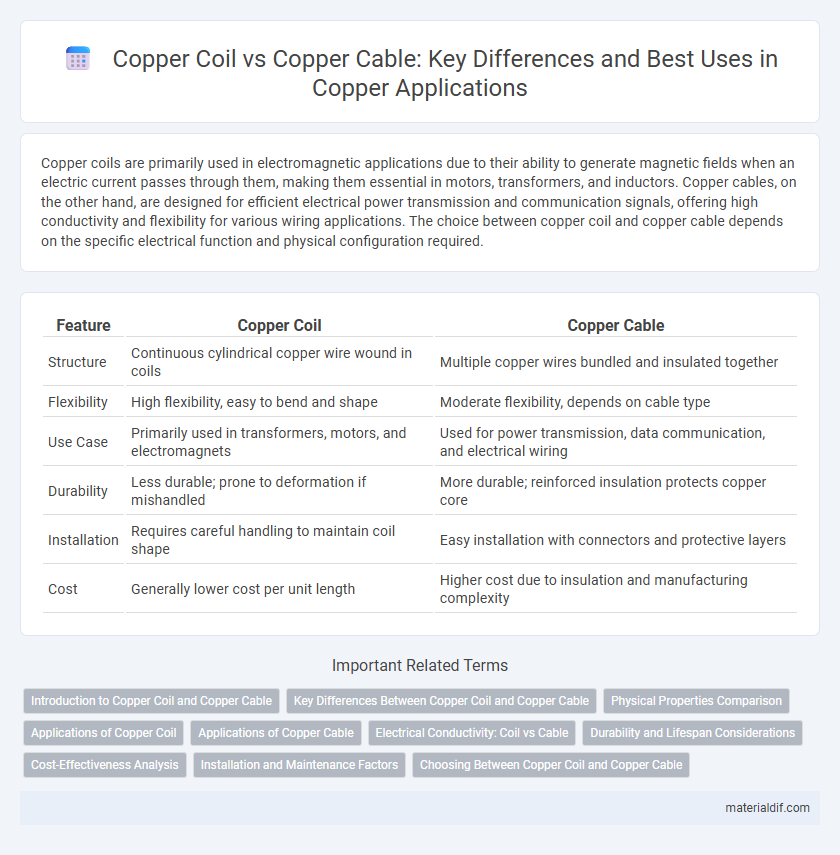

| Feature | Copper Coil | Copper Cable |

|---|---|---|

| Structure | Continuous cylindrical copper wire wound in coils | Multiple copper wires bundled and insulated together |

| Flexibility | High flexibility, easy to bend and shape | Moderate flexibility, depends on cable type |

| Use Case | Primarily used in transformers, motors, and electromagnets | Used for power transmission, data communication, and electrical wiring |

| Durability | Less durable; prone to deformation if mishandled | More durable; reinforced insulation protects copper core |

| Installation | Requires careful handling to maintain coil shape | Easy installation with connectors and protective layers |

| Cost | Generally lower cost per unit length | Higher cost due to insulation and manufacturing complexity |

Introduction to Copper Coil and Copper Cable

Copper coil consists of continuous tubing formed into spiral shapes, commonly used in HVAC systems and electrical transformers for efficient heat transfer and conductivity. Copper cable is composed of multiple copper strands twisted together, designed for flexible electrical wiring and optimal signal transmission in telecommunications and power distribution. Both copper coil and copper cable leverage copper's excellent electrical conductivity and corrosion resistance but serve distinct functions based on their physical forms.

Key Differences Between Copper Coil and Copper Cable

Copper coils consist of continuous loops of copper wire typically used in electromagnetic applications like transformers and inductors, offering high conductivity and flexibility in shaping. Copper cables are composed of multiple copper strands or a solid core insulated for power transmission and communication, designed for durability and efficient electrical performance over distances. Their key difference lies in form and function: coils emphasize inductance and magnetic properties, while cables prioritize current carrying capacity and signal integrity.

Physical Properties Comparison

Copper coils exhibit superior flexibility and durability compared to copper cables, making them ideal for applications requiring repeated bending and shaping. Copper cables, characterized by their solid or stranded wire structure, offer enhanced tensile strength and resistance to mechanical stress suitable for long-distance electrical transmission. Thermal conductivity in copper coils is typically higher due to their compact winding, whereas copper cables provide better protection against external environmental factors through insulation.

Applications of Copper Coil

Copper coils are primarily used in HVAC systems, transformers, and electric motors due to their excellent thermal conductivity and flexibility in winding shapes. Their ability to efficiently transfer heat and electromagnetic energy makes them ideal for refrigeration, air conditioning, and inductive heating applications. Copper coils also provide superior corrosion resistance and durability, ensuring long-lasting performance in industrial and residential equipment.

Applications of Copper Cable

Copper cable is extensively used in electrical wiring for residential, commercial, and industrial buildings due to its excellent conductivity and flexibility. It plays a critical role in telecommunications, enabling high-speed data transmission through twisted pair and coaxial cables. In power distribution systems, copper cable ensures reliable energy delivery with minimal resistance and durability against environmental factors.

Electrical Conductivity: Coil vs Cable

Copper coils exhibit superior electrical conductivity due to their continuous, unbroken copper strands, which minimize resistance and energy loss compared to copper cables composed of multiple twisted wires. The homogeneous structure of copper coils enhances current flow efficiency, making them ideal for electromagnetic applications requiring stable and consistent conductivity. In contrast, copper cables, while flexible and durable, often experience slightly higher resistance at wire junctions, impacting overall electrical performance.

Durability and Lifespan Considerations

Copper coils exhibit superior durability due to their continuous, seamless construction that resists wear and environmental damage, providing a longer lifespan in applications subject to mechanical stress and heat. Copper cables, while flexible and easier to install, may experience faster degradation from bending, stretching, and exposure to corrosive elements. Lifespan considerations favor copper coils in high-stress environments, whereas copper cables suit scenarios prioritizing flexibility and ease of routing.

Cost-Effectiveness Analysis

Copper coils generally offer higher cost-effectiveness in applications requiring durable electromagnetic components due to their efficient conductivity and longer lifespan, despite higher initial manufacturing costs. Copper cables, while cheaper upfront and more flexible for wiring, may incur greater maintenance and replacement expenses over time, especially in high-performance or industrial environments. Analyzing total lifecycle costs reveals copper coils often deliver better value where reliability and performance are critical factors.

Installation and Maintenance Factors

Copper coils offer greater flexibility during installation, making them ideal for applications requiring tight bends and compact layouts, while copper cables provide straightforward installation in longer, linear runs due to their robust, insulated design. Maintenance of copper coils typically involves periodic inspection for insulation wear and coil deformation, whereas copper cables demand regular checks for corrosion, mechanical damage, and secure connections to ensure optimal conductivity. Choosing between copper coils and cables depends on the specific installation environment and maintenance accessibility, optimizing both performance and longevity.

Choosing Between Copper Coil and Copper Cable

When choosing between copper coil and copper cable, consider the specific application requirements such as flexibility, conductivity, and installation environment. Copper coils offer excellent inductance and are ideal for electromagnetic applications, while copper cables provide superior durability and are suited for power transmission and communication. Evaluating factors like current capacity, mechanical strength, and corrosion resistance ensures optimal performance and longevity in electrical systems.

Copper Coil vs Copper Cable Infographic

materialdif.com

materialdif.com