Electroformed copper offers superior precision and intricate detailing due to its layer-by-layer deposition process, making it ideal for custom copper pet tags and accessories. Rolled copper, on the other hand, is created by flattening copper sheets, providing durability and a uniform thickness suitable for more robust, everyday use items. Choosing between electroformed and rolled copper depends on the desired finish, durability, and application for your copper pet products.

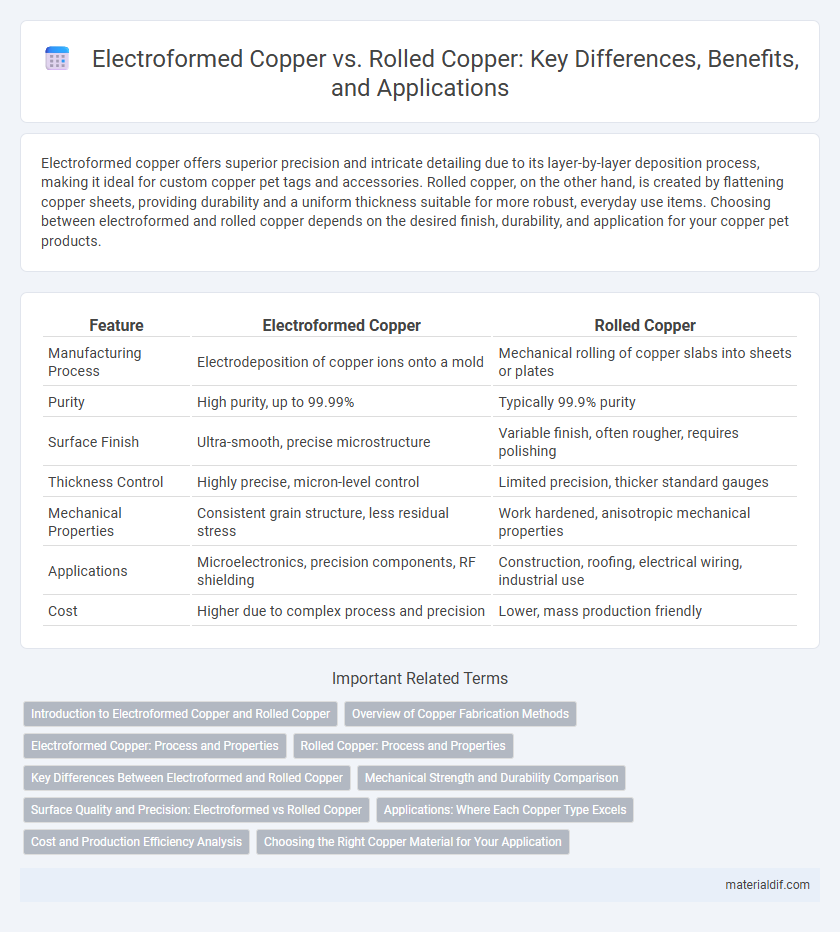

Table of Comparison

| Feature | Electroformed Copper | Rolled Copper |

|---|---|---|

| Manufacturing Process | Electrodeposition of copper ions onto a mold | Mechanical rolling of copper slabs into sheets or plates |

| Purity | High purity, up to 99.99% | Typically 99.9% purity |

| Surface Finish | Ultra-smooth, precise microstructure | Variable finish, often rougher, requires polishing |

| Thickness Control | Highly precise, micron-level control | Limited precision, thicker standard gauges |

| Mechanical Properties | Consistent grain structure, less residual stress | Work hardened, anisotropic mechanical properties |

| Applications | Microelectronics, precision components, RF shielding | Construction, roofing, electrical wiring, industrial use |

| Cost | Higher due to complex process and precision | Lower, mass production friendly |

Introduction to Electroformed Copper and Rolled Copper

Electroformed copper is produced through an electrochemical process that deposits pure copper onto a mold, resulting in precise, high-purity components with intricate shapes and fine surface details. Rolled copper is created by passing copper slabs through rollers to achieve flat, uniform sheets or strips, offering excellent mechanical strength and conductivity for a wide range of industrial applications. Both forms serve distinct purposes: electroformed copper excels in precision and customized applications, whereas rolled copper is preferred for structural uses due to its durability and consistency.

Overview of Copper Fabrication Methods

Electroformed copper offers exceptional precision and complex geometries by depositing copper ions onto a mold in a layer-by-layer process, resulting in high-purity, uniform thickness components ideal for intricate applications. Rolled copper is produced by mechanically compressing copper slabs into sheets or foils, providing durability, consistent thickness, and enhanced mechanical strength suitable for structural and electrical uses. Both methods optimize copper's electrical conductivity and thermal performance but differ in manufacturing flexibility and surface finish quality.

Electroformed Copper: Process and Properties

Electroformed copper is produced through an electrochemical deposition process that creates highly pure, dense, and precise copper components with excellent surface finish and dimensional accuracy. This process allows for intricate shapes and thin walls unattainable by rolled copper, which is manufactured by mechanically compressing copper slabs into sheets or coils. Electroformed copper exhibits superior electrical conductivity, corrosion resistance, and mechanical strength, making it ideal for specialized applications in electronics, aerospace, and medical devices.

Rolled Copper: Process and Properties

Rolled copper is produced by passing copper slabs through heavy rollers to achieve precise thickness and smooth surface finish, enhancing its mechanical strength and uniformity. This process refines the grain structure, resulting in excellent electrical and thermal conductivity, ideal for electrical wiring and heat exchangers. Rolled copper exhibits superior ductility and tensile strength compared to electroformed copper, making it suitable for applications requiring durability and consistent material properties.

Key Differences Between Electroformed and Rolled Copper

Electroformed copper is produced through an electrolytic deposition process, resulting in a highly precise, uniform thickness and enhanced purity, making it ideal for intricate electronic components and microfabrication. Rolled copper, created by mechanically pressing and rolling copper slabs, offers superior mechanical strength and ductility, suitable for structural applications and electrical wiring. Key differences lie in the manufacturing method, surface finish, mechanical properties, and typical use cases, with electroformed copper excelling in precision and purity, while rolled copper provides robustness and versatility.

Mechanical Strength and Durability Comparison

Electroformed copper exhibits superior mechanical strength and durability compared to rolled copper due to its fine-grained microstructure achieved through controlled electrodeposition, resulting in enhanced hardness and resistance to wear. Rolled copper, while offering good ductility and uniform thickness from mechanical deformation processes, often displays lower tensile strength and increased susceptibility to grain boundary weaknesses under stress. The electroforming process optimizes copper's structural integrity, making electroformed copper preferable for applications demanding high mechanical performance and extended service life.

Surface Quality and Precision: Electroformed vs Rolled Copper

Electroformed copper exhibits superior surface quality with a smoother, more uniform texture due to its layer-by-layer deposition process, minimizing defects and surface irregularities. Rolled copper surfaces often show mechanical deformation marks and varying roughness levels caused by the rolling process, which can affect aesthetic and functional precision. Precision in electroformed copper is enhanced by its ability to replicate intricate shapes and fine details accurately, whereas rolled copper is limited by its mechanical stretching, impacting dimensional consistency.

Applications: Where Each Copper Type Excels

Electroformed copper excels in applications requiring intricate shapes and high precision, such as medical devices, microelectronics, and aerospace components due to its excellent conformity and fine detail reproduction. Rolled copper is preferred for electrical wiring, roofing, and architectural elements where strength, durability, and high conductivity are critical, benefiting from its flat, smooth surface and uniform thickness. Each copper type is optimized for specific industry needs, with electroformed copper offering superior customization and rolled copper delivering robust structural performance.

Cost and Production Efficiency Analysis

Electroformed copper offers precise control over thickness and intricate shapes, resulting in higher material utilization but generally incurs higher production costs due to slower deposition rates and specialized equipment. Rolled copper provides faster production speeds and lower costs per unit by using bulk metal sheet processing, making it ideal for large-scale manufacturing with consistent thickness. Evaluating cost-efficiency, rolled copper excels in volume output and affordability, while electroformed copper suits applications requiring fine detail and minimal material waste despite elevated expenses.

Choosing the Right Copper Material for Your Application

Electroformed copper offers superior precision and uniformity, making it ideal for intricate electronic components and high-precision applications. Rolled copper provides enhanced strength and durability, suitable for structural uses and applications requiring mechanical robustness. Selecting the right copper material depends on balancing the need for fine detail and conductivity against mechanical strength and cost efficiency in your specific project.

Electroformed Copper vs Rolled Copper Infographic

materialdif.com

materialdif.com