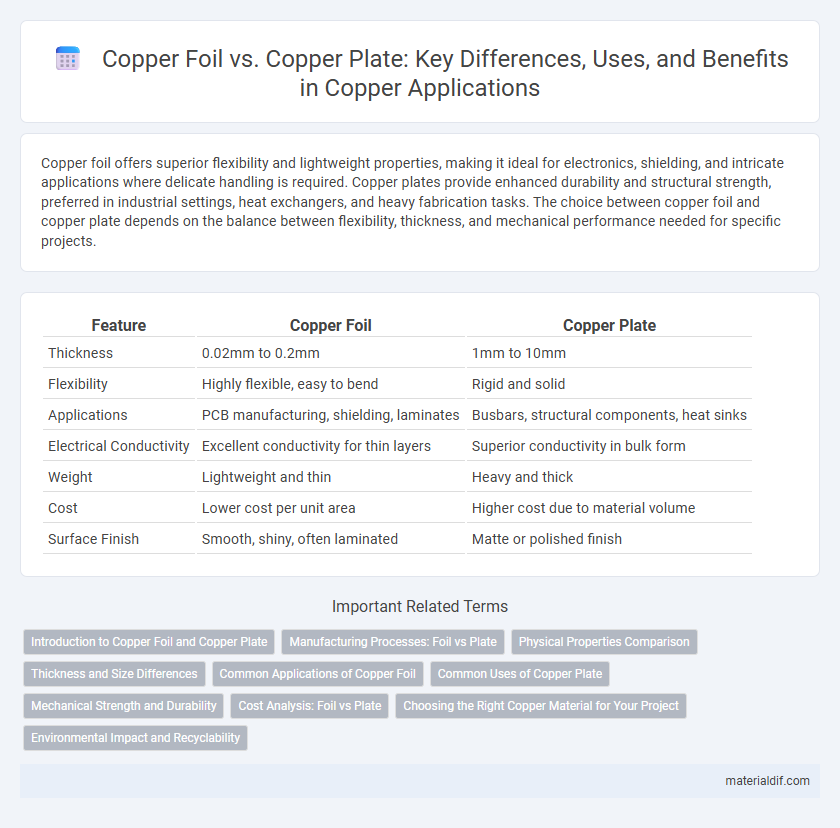

Copper foil offers superior flexibility and lightweight properties, making it ideal for electronics, shielding, and intricate applications where delicate handling is required. Copper plates provide enhanced durability and structural strength, preferred in industrial settings, heat exchangers, and heavy fabrication tasks. The choice between copper foil and copper plate depends on the balance between flexibility, thickness, and mechanical performance needed for specific projects.

Table of Comparison

| Feature | Copper Foil | Copper Plate |

|---|---|---|

| Thickness | 0.02mm to 0.2mm | 1mm to 10mm |

| Flexibility | Highly flexible, easy to bend | Rigid and solid |

| Applications | PCB manufacturing, shielding, laminates | Busbars, structural components, heat sinks |

| Electrical Conductivity | Excellent conductivity for thin layers | Superior conductivity in bulk form |

| Weight | Lightweight and thin | Heavy and thick |

| Cost | Lower cost per unit area | Higher cost due to material volume |

| Surface Finish | Smooth, shiny, often laminated | Matte or polished finish |

Introduction to Copper Foil and Copper Plate

Copper foil is a thin, flexible sheet of copper widely used in electronics, batteries, and shielding applications due to its excellent conductivity and malleability. Copper plates are thicker, rigid metal sheets commonly employed in structural components, heat exchangers, and industrial machinery for their durability and thermal properties. Both forms of copper serve distinct functions, with foil offering precision and flexibility, while plates provide strength and support.

Manufacturing Processes: Foil vs Plate

Copper foil is manufactured using a continuous casting and rolling process that produces extremely thin sheets, typically less than 0.2 mm thick, ideal for electronic applications such as circuit boards. In contrast, copper plates are produced through hot rolling or extrusion followed by cold rolling, resulting in thicker, sturdier sheets often exceeding 0.2 mm, suitable for structural and industrial uses. The foil's precise thickness control and smooth surface finish distinguish it from the plate's robust mechanical strength and durability in manufacturing processes.

Physical Properties Comparison

Copper foil exhibits a thin, flexible structure with high conductivity and excellent malleability, making it ideal for electronic circuitry and flexible devices. In contrast, copper plates are rigid, thicker, and provide superior mechanical strength and durability, often used in structural applications and heat exchangers. Both forms maintain high thermal and electrical conductivity, but foil's lightweight nature contrasts sharply with the robustness of copper plates.

Thickness and Size Differences

Copper foil typically ranges from 0.001 inches to 0.01 inches in thickness, making it significantly thinner and more flexible than copper plates, which usually start at 0.04 inches and can exceed several inches thick. Copper foil is available in wider rolls or sheets primarily used for electrical applications and shielding, while copper plates come in limited sheet sizes suited for structural or industrial uses. The size and thickness differences determine their suitability, with foil favored for precision layering and plates chosen for durability and strength.

Common Applications of Copper Foil

Copper foil is widely used in electronics manufacturing, particularly for flexible printed circuit boards (PCBs) and electromagnetic shielding due to its excellent conductivity and malleability. It serves crucial functions in lithium-ion battery anodes, enhancing energy storage efficiency and thermal management. Copper foil's thin, ductile properties make it ideal for decorative laminates, heat exchangers, and specialized industrial applications requiring lightweight, conductive materials.

Common Uses of Copper Plate

Copper plates are commonly used in electrical applications due to their excellent conductivity and durability, making them ideal for circuit boards, busbars, and heat exchangers. They serve as a key material in architectural and decorative projects, providing corrosion resistance and aesthetic appeal in roofing and wall cladding. Industrially, copper plates are utilized for manufacturing heavy-duty components such as marine hardware and industrial machinery parts.

Mechanical Strength and Durability

Copper foil offers excellent flexibility and is ideal for applications requiring lightweight, thin materials, but it generally has lower mechanical strength compared to copper plates. Copper plates provide superior durability and higher tensile strength, making them suitable for heavy-duty industrial uses and environments subject to mechanical stress. The enhanced robustness of copper plates ensures longer lifespan and better resistance to deformation under load.

Cost Analysis: Foil vs Plate

Copper foil generally offers a lower cost per unit weight compared to copper plates due to its thinness and fabrication efficiency, making it ideal for applications requiring lightweight conductive materials. Copper plates, while more expensive upfront owing to their thicker dimensions and higher raw material usage, provide superior mechanical strength and durability suited for structural or heavy-duty electrical uses. Analyzing total lifecycle costs reveals copper foil reduces expenses in mass production of electronics, whereas copper plate incurs higher initial costs but potentially lower maintenance costs in industrial settings.

Choosing the Right Copper Material for Your Project

Copper foil offers flexibility and superior electrical conductivity, making it ideal for electronics and circuit board applications, while copper plate provides greater thickness and mechanical strength suitable for structural and heavy-duty projects. Selecting between copper foil and copper plate depends on project requirements such as thickness, electrical performance, and durability. Consider factors like thermal conductivity, corrosion resistance, and fabrication methods to ensure optimal material performance for your specific application.

Environmental Impact and Recyclability

Copper foil, being thinner and used in smaller quantities compared to copper plates, results in lower raw material consumption and reduced environmental footprint during production. Both copper foil and copper plates are highly recyclable, retaining their properties through multiple recycling processes, but the foil's lightweight nature facilitates more efficient transportation and recycling logistics. The production of copper plates typically involves higher energy input and generates more waste, whereas copper foil manufacturing emphasizes precision and minimal resource use, improving overall sustainability.

Copper Foil vs Copper Plate Infographic

materialdif.com

materialdif.com