C11000 copper contains 99.9% pure copper with trace amounts of oxygen, providing excellent electrical conductivity and improved mechanical strength compared to C10200 copper, which is highly oxygen-free but less processable. C11000 is widely used in electrical wiring and industrial applications due to its balance of conductivity and durability, while C10200 is preferred in critical electronic components requiring superior signal integrity and minimal impurities. Selecting between these alloys depends on the required electrical performance, manufacturing capability, and environmental resistance.

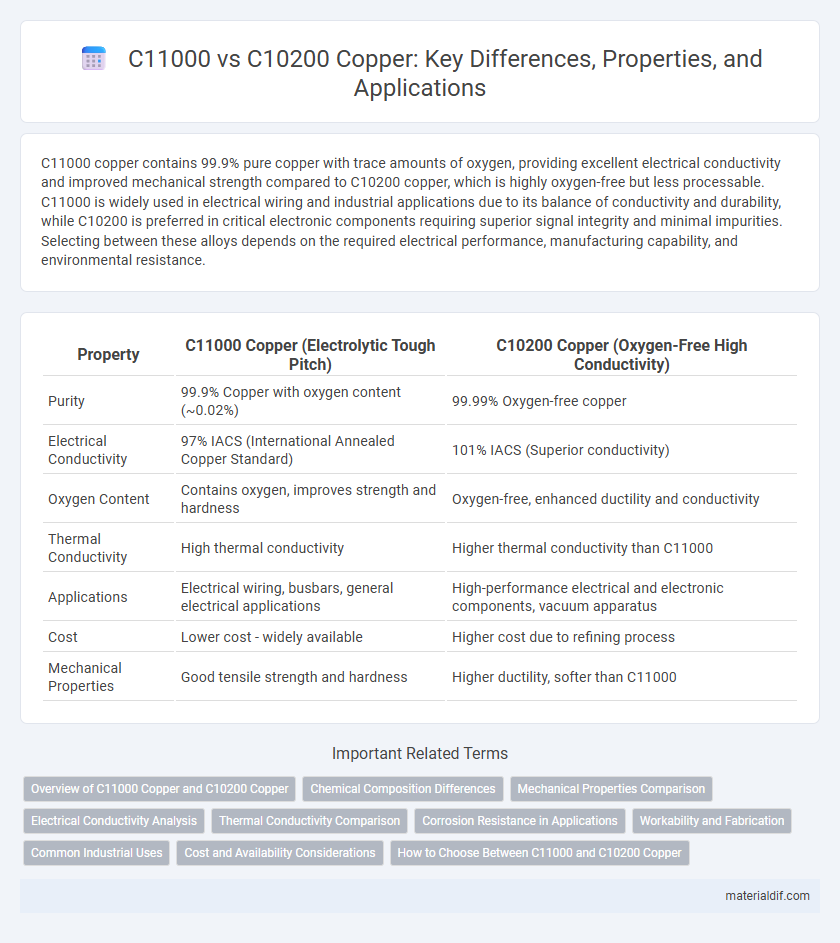

Table of Comparison

| Property | C11000 Copper (Electrolytic Tough Pitch) | C10200 Copper (Oxygen-Free High Conductivity) |

|---|---|---|

| Purity | 99.9% Copper with oxygen content (~0.02%) | 99.99% Oxygen-free copper |

| Electrical Conductivity | 97% IACS (International Annealed Copper Standard) | 101% IACS (Superior conductivity) |

| Oxygen Content | Contains oxygen, improves strength and hardness | Oxygen-free, enhanced ductility and conductivity |

| Thermal Conductivity | High thermal conductivity | Higher thermal conductivity than C11000 |

| Applications | Electrical wiring, busbars, general electrical applications | High-performance electrical and electronic components, vacuum apparatus |

| Cost | Lower cost - widely available | Higher cost due to refining process |

| Mechanical Properties | Good tensile strength and hardness | Higher ductility, softer than C11000 |

Overview of C11000 Copper and C10200 Copper

C11000 Copper, known as electrolytic tough pitch (ETP) copper, contains oxygen up to 0.04%, offering excellent electrical conductivity of about 101% IACS and superior thermal performance, making it ideal for electrical and electronic applications. C10200 Copper, or oxygen-free (OF) copper, has a minimum purity of 99.95% with oxygen content below 0.001%, providing enhanced ductility and corrosion resistance, preferred for high-purity requirements in aerospace and vacuum technology. Both alloys exhibit excellent machinability and formability, but C11000 is favored for general conductivity needs, while C10200 suits specialized environments demanding higher purity and minimal oxygen content.

Chemical Composition Differences

C11000 copper primarily consists of 99.90% pure copper with minimal impurities such as oxygen and trace elements, while C10200 copper contains 99.99% pure copper with even fewer impurities, making it the highest purity oxygen-free copper grade. The chemical composition difference lies in the oxygen content, where C11000 is oxygen-free copper with 0.02% max oxygen, and C10200 is oxygen-free high conductivity (OFHC) copper with essentially zero oxygen and controlled levels of other impurity elements. These variations in chemical purity impact electrical conductivity, corrosion resistance, and suitability for high-performance electrical and electronic applications.

Mechanical Properties Comparison

C11000 copper, also known as electrolytic tough pitch (ETP) copper, typically exhibits higher tensile strength and improved mechanical durability compared to C10200 (oxygen-free copper). C11000 copper offers tensile strength values around 210-250 MPa, while C10200 generally ranges between 200-240 MPa, making C11000 preferable for applications requiring enhanced toughness. Both alloys maintain excellent conductivity, but C11000's mechanical properties provide better resistance to deformation under stress.

Electrical Conductivity Analysis

C11000 copper exhibits higher electrical conductivity, typically around 101% IACS, compared to C10200 copper, which usually ranges near 100% IACS. This superior conductivity makes C11000 the preferred choice for electrical applications requiring minimal resistance and maximum efficiency. Variations in purity and alloying elements contribute to the slight differences in electrical performance between these two copper grades.

Thermal Conductivity Comparison

C11000 copper, known as electrolytic tough pitch (ETP) copper, exhibits a thermal conductivity of approximately 385 W/m*K, making it highly efficient for heat transfer applications. In comparison, C10200 copper, or oxygen-free copper, offers slightly higher thermal conductivity, around 400 W/m*K, due to its minimal oxygen content that reduces scattering of heat-carrying electrons. The enhanced thermal conductivity of C10200 copper makes it preferable in high-performance electrical and thermal systems requiring superior heat dissipation.

Corrosion Resistance in Applications

C11000 copper, also known as electrolytic tough pitch (ETP) copper, contains a small amount of oxygen that improves its electrical conductivity but makes it more prone to certain types of corrosion in moist or acidic environments. C10200 copper is oxygen-free copper, providing superior corrosion resistance, especially in applications exposed to harsh chemical or marine environments. The enhanced purity of C10200 reduces the risk of hydrogen embrittlement and improves long-term durability in critical industrial uses.

Workability and Fabrication

C11000 Copper, with its higher purity of approximately 99.9%, offers superior electrical conductivity but presents moderate workability, making it suitable for detailed fabrication processes. In contrast, C10200 Copper, slightly less pure at around 99.5%, exhibits enhanced malleability and ductility, facilitating easier forming and shaping during manufacturing. Both alloys provide excellent corrosion resistance, but C10200's improved workability favors applications requiring extensive bending or intricate component fabrication.

Common Industrial Uses

C11000 copper, also known as electrolytic tough pitch (ETP) copper, is widely used in electrical wiring, plumbing, and heat exchangers due to its high electrical conductivity and good thermal properties. C10200 copper, or oxygen-free electronic (OFE) copper, is preferred for high-performance electrical components, vacuum systems, and cryogenics because of its superior purity and minimal oxygen content. Both grades are essential in industrial applications where conductivity and corrosion resistance are critical, with C11000 favored for general electrical installations and C10200 selected for specialized electronic uses.

Cost and Availability Considerations

C11000 copper, also known as electrolytic tough pitch (ETP) copper, is generally more affordable and widely available due to its higher demand and large-scale production. C10200 copper, or oxygen-free copper (OFHC), typically costs more because of its superior purity and specialized manufacturing processes, leading to limited availability in comparison. Choosing between C11000 and C10200 copper depends on budget constraints and the required material properties for specific industrial or electrical applications.

How to Choose Between C11000 and C10200 Copper

Choosing between C11000 and C10200 copper depends on application requirements such as electrical conductivity and mechanical strength. C11000, also known as Electrolytic Tough Pitch (ETP) copper, offers high electrical conductivity of approximately 101% IACS, making it ideal for electrical wiring and components. C10200 copper provides slightly higher purity with 99.99% minimum copper content, offering superior corrosion resistance and ductility for specialized industrial uses where those properties are critical.

C11000 Copper vs C10200 Copper Infographic

materialdif.com

materialdif.com