Annealed copper is softened through a heat treatment process that improves its ductility and electrical conductivity, making it ideal for applications requiring extensive bending and shaping. Hard drawn copper, on the other hand, is mechanically strengthened through cold working, resulting in higher tensile strength but decreased flexibility. Choosing between annealed and hard drawn copper depends on the specific requirements of conductivity, malleability, and mechanical durability in electrical or plumbing projects.

Table of Comparison

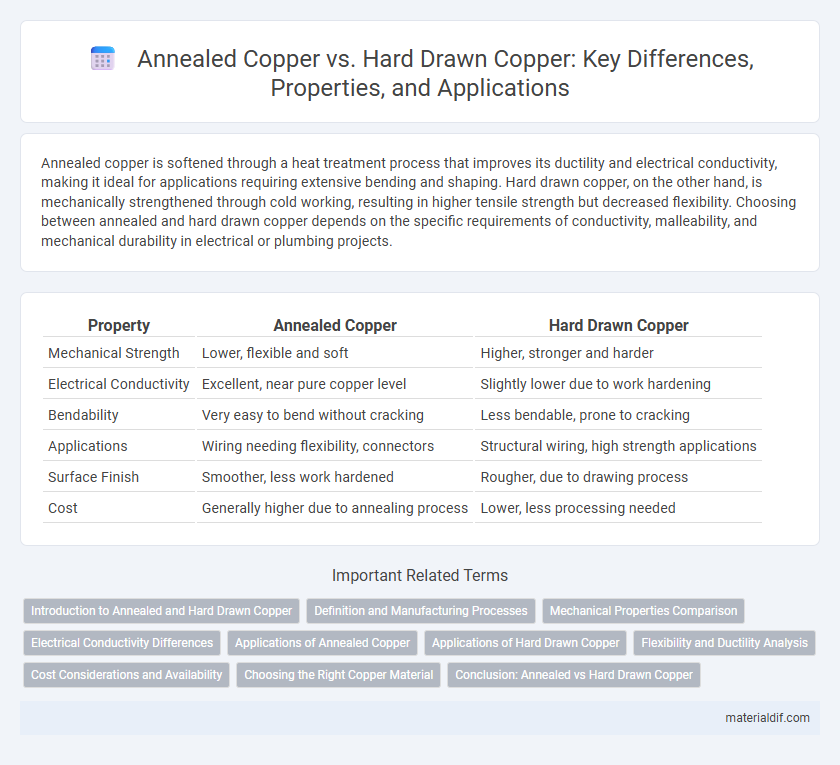

| Property | Annealed Copper | Hard Drawn Copper |

|---|---|---|

| Mechanical Strength | Lower, flexible and soft | Higher, stronger and harder |

| Electrical Conductivity | Excellent, near pure copper level | Slightly lower due to work hardening |

| Bendability | Very easy to bend without cracking | Less bendable, prone to cracking |

| Applications | Wiring needing flexibility, connectors | Structural wiring, high strength applications |

| Surface Finish | Smoother, less work hardened | Rougher, due to drawing process |

| Cost | Generally higher due to annealing process | Lower, less processing needed |

Introduction to Annealed and Hard Drawn Copper

Annealed copper undergoes a heat treatment process that softens the metal, enhancing its ductility and electrical conductivity, making it ideal for applications requiring flexibility and ease of shaping. Hard drawn copper is produced by cold working the metal, resulting in increased strength and stiffness, which is essential for structural components and electrical wiring subjected to mechanical stress. Understanding the distinct properties of annealed versus hard drawn copper aids in selecting the appropriate type for specific industrial and electrical applications.

Definition and Manufacturing Processes

Annealed copper undergoes a heat treatment process that softens the metal by relieving internal stresses, enhancing its ductility and electrical conductivity. Hard drawn copper, produced through cold working without heat treatment, retains higher tensile strength and hardness but exhibits reduced flexibility compared to annealed copper. The annealing process involves heating copper to a specific temperature followed by controlled cooling, whereas hard drawn copper is shaped through mechanical deformation such as drawing through dies.

Mechanical Properties Comparison

Annealed copper exhibits higher ductility and improved electrical conductivity due to its soft, recrystallized structure, making it ideal for applications requiring extensive bending and shaping. Hard drawn copper, in contrast, offers greater tensile strength and hardness as a result of strain hardening during cold working, but it sacrifices some flexibility and conductivity. The choice between annealed and hard drawn copper depends on whether mechanical strength or malleability is prioritized in the application.

Electrical Conductivity Differences

Annealed copper exhibits superior electrical conductivity compared to hard drawn copper due to its softer, more ductile structure that allows electrons to flow with less resistance. Hard drawn copper undergoes mechanical deformation, increasing its hardness and tensile strength but reducing its electrical conductivity by introducing dislocations and grain boundaries that impede electron movement. The conductivity of annealed copper typically ranges near 100% IACS (International Annealed Copper Standard), while hard drawn copper conductivity drops to approximately 97-98% IACS.

Applications of Annealed Copper

Annealed copper, characterized by its enhanced ductility and softness due to heat treatment, is extensively used in electrical wiring, plumbing, and roofing applications where flexibility and ease of shaping are essential. Its superior conductivity and corrosion resistance make it ideal for transformers, switchgear, and telecommunications cables. Unlike hard drawn copper, annealed copper allows for easier bending and forming without cracking, which is crucial in manufacturing complex components and connections.

Applications of Hard Drawn Copper

Hard drawn copper is widely used in electrical wiring, grounding systems, and manufacturing of electrical conductors due to its enhanced tensile strength and dimensional stability. Its ability to maintain shape under mechanical stress makes it ideal for applications requiring rigid and durable copper components such as power transmission cables and spring contacts. Compared to annealed copper, hard drawn copper resists deformation, ensuring reliability in construction and industrial electrical installations.

Flexibility and Ductility Analysis

Annealed copper exhibits superior flexibility and increased ductility due to its heat treatment process, allowing it to bend and stretch without cracking. Hard-drawn copper, in contrast, is mechanically strengthened through cold working, resulting in reduced flexibility and lower ductility but enhanced tensile strength. These properties make annealed copper ideal for applications requiring frequent bending, while hard-drawn copper suits rigid installations demanding higher mechanical durability.

Cost Considerations and Availability

Annealed copper generally costs more than hard drawn copper due to its softer, more malleable nature, which requires additional processing. Hard drawn copper tends to be more readily available and less expensive, making it a preferred choice for applications needing higher tensile strength and cost efficiency. Availability of annealed copper may be limited in bulk quantities compared to the more commonly stocked hard drawn copper in electrical and plumbing supplies.

Choosing the Right Copper Material

Annealed copper offers superior flexibility and excellent electrical conductivity, making it ideal for applications requiring frequent bending or shaping. Hard drawn copper provides enhanced tensile strength and durability, suitable for high-stress environments or structural uses. Selecting the right copper material depends on balancing mechanical strength with flexibility demands in specific electrical or mechanical projects.

Conclusion: Annealed vs Hard Drawn Copper

Annealed copper offers superior flexibility and enhanced electrical conductivity, making it ideal for applications requiring frequent bending or shaping. Hard drawn copper provides increased tensile strength and rigidity, suitable for structural tasks demanding mechanical durability. Selecting between annealed and hard drawn copper depends on balancing the need for electrical performance against mechanical resilience in specific projects.

Annealed Copper vs Hard Drawn Copper Infographic

materialdif.com

materialdif.com