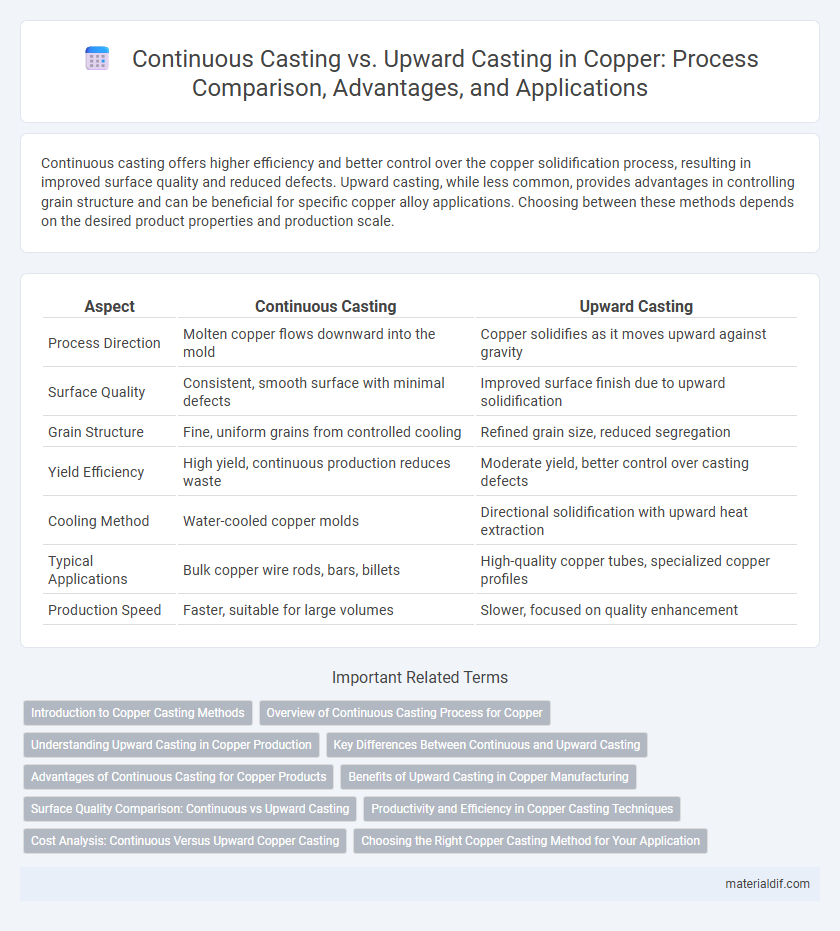

Continuous casting offers higher efficiency and better control over the copper solidification process, resulting in improved surface quality and reduced defects. Upward casting, while less common, provides advantages in controlling grain structure and can be beneficial for specific copper alloy applications. Choosing between these methods depends on the desired product properties and production scale.

Table of Comparison

| Aspect | Continuous Casting | Upward Casting |

|---|---|---|

| Process Direction | Molten copper flows downward into the mold | Copper solidifies as it moves upward against gravity |

| Surface Quality | Consistent, smooth surface with minimal defects | Improved surface finish due to upward solidification |

| Grain Structure | Fine, uniform grains from controlled cooling | Refined grain size, reduced segregation |

| Yield Efficiency | High yield, continuous production reduces waste | Moderate yield, better control over casting defects |

| Cooling Method | Water-cooled copper molds | Directional solidification with upward heat extraction |

| Typical Applications | Bulk copper wire rods, bars, billets | High-quality copper tubes, specialized copper profiles |

| Production Speed | Faster, suitable for large volumes | Slower, focused on quality enhancement |

Introduction to Copper Casting Methods

Copper casting methods include continuous casting and upward casting, each offering distinct advantages for copper production. Continuous casting enables high-volume, uniform copper billets with improved mechanical properties and surface quality, optimizing industrial throughput. Upward casting, often used for specialized copper alloys, allows better control over solidification, reducing defects and enhancing microstructural characteristics.

Overview of Continuous Casting Process for Copper

Continuous casting of copper involves the direct solidification of molten copper into a semi-finished billet, bloom, or slab, enabling efficient downstream processing. This process maintains a consistent temperature gradient and controlled cooling rates to ensure uniform microstructure and mechanical properties in the copper product. Compared to upward casting, continuous casting provides higher productivity, reduced defects, and improved surface quality, optimizing material performance for electrical and industrial applications.

Understanding Upward Casting in Copper Production

Upward casting in copper production involves pouring molten copper into a mold from the bottom or center, allowing the metal to solidify as it rises, which promotes uniform grain structure and reduces impurities. This method enhances the quality and mechanical properties of copper by minimizing turbulence and gas entrapment during solidification. Compared to continuous casting, upward casting offers improved control over cooling rates and solidification fronts, resulting in higher purity and fewer defects in the final copper product.

Key Differences Between Continuous and Upward Casting

Continuous casting involves the steady extraction of molten copper through a cooling mold, producing uniform billets or slabs with high efficiency and minimal manual intervention. Upward casting, on the other hand, feeds molten copper from below into a mold moving vertically upward, allowing better control of solidification but typically slower production rates. Key differences include process orientation, cooling dynamics, and overall throughput, with continuous casting favoring high-volume copper manufacturing and upward casting providing enhanced quality control for specialized applications.

Advantages of Continuous Casting for Copper Products

Continuous casting for copper products offers superior efficiency by enabling the direct solidification of molten copper into semi-finished shapes, minimizing waste and energy consumption compared to upward casting. It ensures improved metallurgical quality with a more uniform microstructure and reduced segregation, resulting in enhanced mechanical properties and electrical conductivity. The process supports higher production rates and consistent product dimensions, leading to cost savings and increased throughput in copper manufacturing.

Benefits of Upward Casting in Copper Manufacturing

Upward casting in copper manufacturing enhances molten metal flow control, reducing defects such as porosity and segregation compared to continuous casting. This method improves the grain structure and mechanical properties of copper products, resulting in higher conductivity and tensile strength. The vertical solidification process also enables better heat extraction, leading to increased production efficiency and consistent quality in copper billets and slabs.

Surface Quality Comparison: Continuous vs Upward Casting

Continuous casting of copper produces a smoother and more uniform surface finish due to its steady solidification process, reducing surface defects such as cracks and porosity. In contrast, upward casting often results in higher surface roughness and irregularities caused by inconsistent cooling rates and turbulence during the metal flow. Thus, continuous casting is generally preferred for applications demanding superior surface quality and minimal post-processing.

Productivity and Efficiency in Copper Casting Techniques

Continuous casting in copper production enhances productivity by allowing uninterrupted solidification of molten copper, reducing casting defects and material waste. Upward casting, while beneficial for specific alloy compositions, often results in slower throughput and increased energy consumption due to its batch processing nature. Optimizing continuous casting parameters leads to higher efficiency, lower operational costs, and improved copper billet quality, making it the preferred method in large-scale copper manufacturing.

Cost Analysis: Continuous Versus Upward Copper Casting

Continuous casting of copper offers lower operational costs compared to upward casting due to higher production efficiency and reduced energy consumption per ton of output. Upward casting typically incurs increased labor and maintenance expenses owing to slower production rates and more complex mold handling. Lifecycle cost analysis reveals continuous casting as the more economically viable method for large-scale copper manufacturing.

Choosing the Right Copper Casting Method for Your Application

Continuous casting offers precise control over copper's solidification, resulting in uniform grain structure and improved mechanical properties ideal for high-volume production of rods and billets. Upward casting, with its slower cooling rate, enhances compositional homogeneity and is suited for applications requiring superior metallurgical quality and intricate geometries. Selecting the appropriate copper casting method depends on balancing production scale, desired microstructural characteristics, and final product specifications.

Continuous Casting vs Upward Casting Infographic

materialdif.com

materialdif.com