Copper plates offer a flat, uniform surface ideal for crafting decorative items and intricate metalwork, while copper bars provide a sturdy, solid form suited for structural applications and heavy-duty projects. Plates are typically thinner and more malleable, enabling precise bending and shaping, whereas bars have greater thickness and strength, making them better for load-bearing uses. Choosing between copper plate and copper bar depends on whether flexibility or durability is prioritized in the pet accessory design.

Table of Comparison

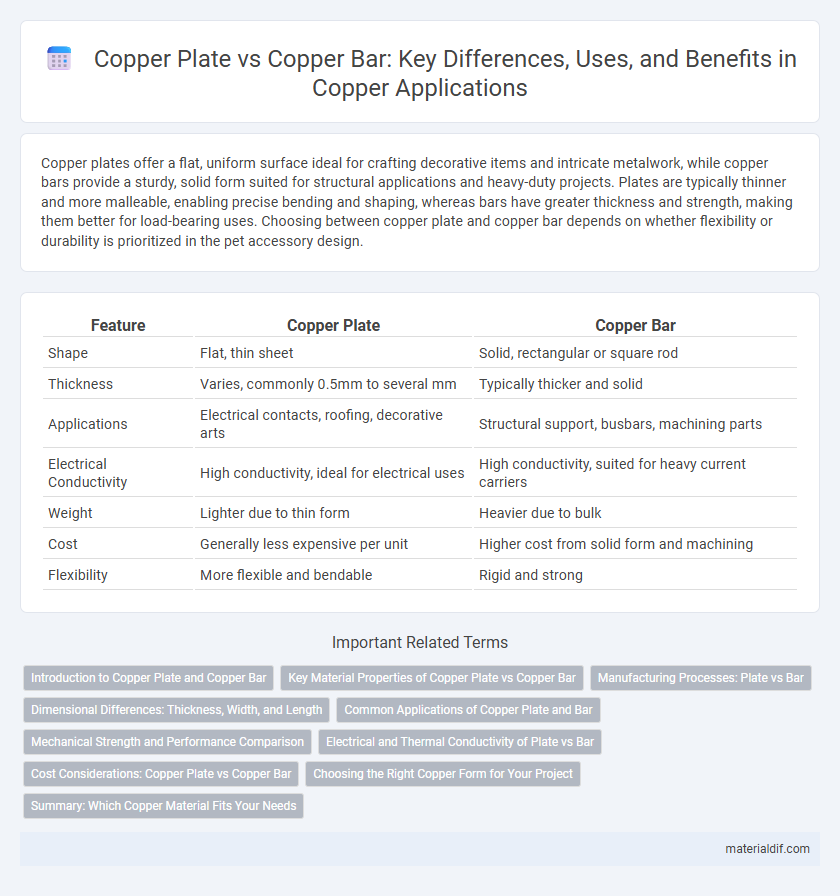

| Feature | Copper Plate | Copper Bar |

|---|---|---|

| Shape | Flat, thin sheet | Solid, rectangular or square rod |

| Thickness | Varies, commonly 0.5mm to several mm | Typically thicker and solid |

| Applications | Electrical contacts, roofing, decorative arts | Structural support, busbars, machining parts |

| Electrical Conductivity | High conductivity, ideal for electrical uses | High conductivity, suited for heavy current carriers |

| Weight | Lighter due to thin form | Heavier due to bulk |

| Cost | Generally less expensive per unit | Higher cost from solid form and machining |

| Flexibility | More flexible and bendable | Rigid and strong |

Introduction to Copper Plate and Copper Bar

Copper plates and copper bars serve distinct roles in electrical and construction applications, each tailored for specific structural and conductive needs. Copper plates are flat, thin sheets primarily used in grounding systems, electrical busbars, and architectural cladding due to their large surface area and excellent conductivity. Copper bars, thicker and more rigid, are commonly utilized in manufacturing, heavy-duty electrical connections, and mechanical components where strength and current-carrying capacity are crucial.

Key Material Properties of Copper Plate vs Copper Bar

Copper plates exhibit superior thermal conductivity and corrosion resistance compared to copper bars, making them ideal for heat exchangers and marine applications. Copper bars provide higher mechanical strength and are preferred for structural components and electrical terminal connectors. Both materials possess excellent electrical conductivity, but copper bars typically have greater dimensional stability under mechanical stress.

Manufacturing Processes: Plate vs Bar

Copper plates are typically produced through hot rolling and annealing processes, resulting in flat, thin sheets with uniform thickness ideal for electrical, construction, and industrial applications. Copper bars undergo extrusion or continuous casting, creating solid, elongated sections with high strength and dimensional precision, suitable for mechanical parts and structural components. The manufacturing choice between plates and bars depends on the required form factor, mechanical properties, and end-use performance in various industries.

Dimensional Differences: Thickness, Width, and Length

Copper plates typically offer greater thickness, ranging from 1 mm to over 10 mm, compared to copper bars which are generally thicker but narrower in cross-section. Copper plates are produced in large flat sheets with varying widths up to several meters and lengths customized to application needs, while copper bars come in standard rectangular or square cross-sections with fixed widths and longer lengths for structural or electrical use. Dimensional differences directly influence their suitability, with plates favored for surface applications requiring broad coverage and bars preferred for load-bearing or conductive tasks requiring specific shapes and sizes.

Common Applications of Copper Plate and Bar

Copper plates are widely used in electrical and plumbing applications due to their excellent conductivity and corrosion resistance, making them ideal for circuit boards, roofing, and heat exchangers. Copper bars are commonly utilized in construction, electrical grounding systems, and manufacturing of mechanical components because of their strength and versatility. Both forms are essential in industrial settings, with plates favored for flat, sheet-based applications and bars preferred for structural support and conductive frameworks.

Mechanical Strength and Performance Comparison

Copper bars exhibit higher mechanical strength and superior load-bearing capacity compared to copper plates, making them ideal for structural applications requiring enhanced durability. The grain structure in copper bars is typically more uniform, contributing to improved tensile strength and resistance to deformation under stress. Copper plates, while offering greater surface area for heat dissipation and conductivity, generally have lower mechanical performance in terms of impact resistance and fatigue strength relative to copper bars.

Electrical and Thermal Conductivity of Plate vs Bar

Copper plates exhibit superior thermal conductivity due to their larger surface area, enabling more efficient heat dissipation compared to copper bars. In electrical applications, copper bars typically provide better directional electrical conductivity because their elongated shape allows for easier current flow along their length. The choice between copper plate and copper bar depends on the specific requirements for heat transfer efficiency and electrical current conduction in the intended application.

Cost Considerations: Copper Plate vs Copper Bar

Copper bars generally cost less per unit weight than copper plates due to simpler manufacturing processes and lower material thickness requirements. Copper plates require more raw material and precise rolling or extrusion techniques, leading to higher production costs and pricing. Selecting between copper plate and copper bar depends on project-specific factors such as mechanical strength needs and budget constraints.

Choosing the Right Copper Form for Your Project

Copper plates offer a flat, smooth surface ideal for precise fabrication and electrical applications requiring consistent conductivity, while copper bars provide robust structural support in construction and heavy machinery. Selecting the right copper form depends on the project's mechanical strength, conductivity needs, and fabrication methods. Consider copper plates for detailed, high-conductivity tasks and copper bars for durability and load-bearing applications.

Summary: Which Copper Material Fits Your Needs

Copper plates offer broad, flat surfaces ideal for electrical grounding and structural applications, while copper bars provide enhanced strength and are preferred in mechanical and industrial uses. The choice depends on requirements such as conductivity, durability, shape, and ease of installation. Copper plates suit projects needing large surface area coverage, whereas copper bars are better for load-bearing and intricate fabrication tasks.

Copper Plate vs Copper Bar Infographic

materialdif.com

materialdif.com