Copper clad offers a cost-effective alternative to solid copper by combining a thin layer of copper with a core material, providing good conductivity and corrosion resistance at a lower price. Solid copper, used extensively in electrical wiring and plumbing, delivers superior durability, higher conductivity, and excellent corrosion resistance critical for long-term performance. Choosing between copper clad and solid copper depends on budget, application requirements, and desired electrical or thermal efficiency.

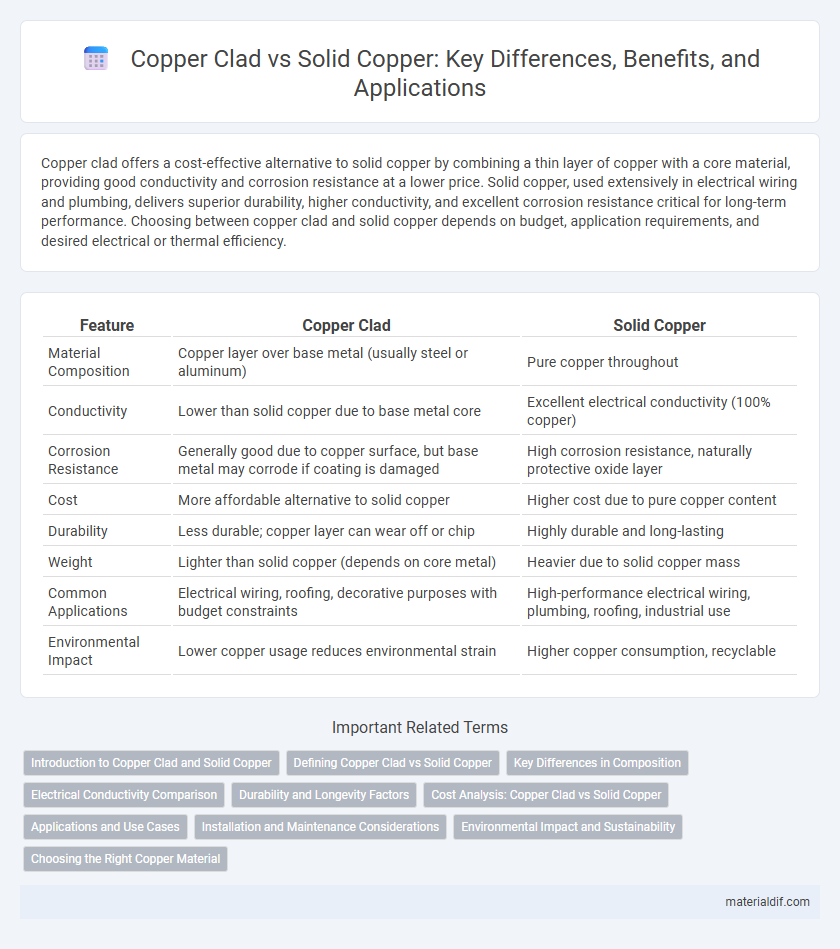

Table of Comparison

| Feature | Copper Clad | Solid Copper |

|---|---|---|

| Material Composition | Copper layer over base metal (usually steel or aluminum) | Pure copper throughout |

| Conductivity | Lower than solid copper due to base metal core | Excellent electrical conductivity (100% copper) |

| Corrosion Resistance | Generally good due to copper surface, but base metal may corrode if coating is damaged | High corrosion resistance, naturally protective oxide layer |

| Cost | More affordable alternative to solid copper | Higher cost due to pure copper content |

| Durability | Less durable; copper layer can wear off or chip | Highly durable and long-lasting |

| Weight | Lighter than solid copper (depends on core metal) | Heavier due to solid copper mass |

| Common Applications | Electrical wiring, roofing, decorative purposes with budget constraints | High-performance electrical wiring, plumbing, roofing, industrial use |

| Environmental Impact | Lower copper usage reduces environmental strain | Higher copper consumption, recyclable |

Introduction to Copper Clad and Solid Copper

Copper clad consists of a core material, usually aluminum or steel, coated with a thin layer of copper to combine conductivity with mechanical strength and cost efficiency. Solid copper, composed entirely of copper, offers superior electrical conductivity, corrosion resistance, and durability ideal for high-performance electrical applications. Choosing between copper clad and solid copper depends on factors such as conductivity requirements, mechanical strength, weight considerations, and budget constraints.

Defining Copper Clad vs Solid Copper

Copper clad consists of a thin layer of copper bonded to a base metal like aluminum, combining conductivity and cost-effectiveness, whereas solid copper is a pure metal element known for its superior electrical and thermal conductivity. Solid copper offers higher corrosion resistance and durability, making it ideal for heavy-duty electrical applications and grounding systems. Copper clad materials reduce weight and material costs while maintaining adequate conductivity for many electronic and industrial uses.

Key Differences in Composition

Copper clad consists of a thin layer of pure copper bonded to a base metal, typically aluminum or steel, creating a composite material with enhanced conductivity and corrosion resistance at a lower cost. Solid copper is composed entirely of copper, offering superior electrical and thermal conductivity, durability, and solderability but at a higher price and weight. The key differences in composition between copper clad and solid copper directly affect their performance in electrical, plumbing, and industrial applications.

Electrical Conductivity Comparison

Copper clad materials offer a cost-effective alternative with decent electrical conductivity, typically ranging from 85% to 95% of pure copper's conductivity. Solid copper exhibits superior electrical conductivity, consistently rated at 100% IACS (International Annealed Copper Standard), making it ideal for high-performance electrical applications. The choice between copper clad and solid copper depends on balancing conductivity requirements and budget constraints in electrical systems.

Durability and Longevity Factors

Copper cladding involves bonding a thin layer of copper to a base metal, offering enhanced corrosion resistance but reduced overall durability compared to solid copper, which maintains consistent strength and wear resistance throughout its thickness. Solid copper demonstrates superior longevity in harsh environments due to its uniform composition, while copper cladding may delaminate or wear through over time under heavy mechanical stress. The choice between copper clad and solid copper hinges on the balance of budget constraints and the expected lifespan, with solid copper preferred for long-term structural applications requiring maximum durability.

Cost Analysis: Copper Clad vs Solid Copper

Copper clad materials typically offer a lower cost alternative to solid copper due to reduced copper content and manufacturing efficiencies. Solid copper provides superior electrical conductivity and durability but comes with higher raw material and production expenses. Evaluating the cost-effectiveness depends on application requirements, with copper clad favored for budget-sensitive projects and solid copper preferred in high-performance settings.

Applications and Use Cases

Copper clad materials offer cost-effective solutions for electrical grounding and shielding in telecommunications and automotive industries, leveraging their lightweight properties and ease of fabrication. Solid copper is preferred in high-conductivity applications such as power distribution, electrical wiring, and HVAC systems due to its superior electrical and thermal performance. Both materials serve critical roles in circuit board manufacturing, with solid copper enhancing signal integrity in high-frequency electronics and copper clad substrates supporting multilayer PCB designs.

Installation and Maintenance Considerations

Copper clad offers easier installation due to its lightweight nature and flexibility, reducing labor time and effort compared to solid copper. Solid copper, while heavier and more rigid, provides superior durability and longevity, minimizing maintenance frequency. Maintenance for copper clad typically requires more frequent inspection for corrosion at the bonding layer, whereas solid copper is more resistant to environmental wear over time.

Environmental Impact and Sustainability

Copper clad materials involve a thin layer of copper bonded to a base metal, reducing copper usage and lowering environmental impact through resource conservation compared to solid copper products, which require more extensive mining and processing. Solid copper, while more durable and fully recyclable, demands greater energy consumption and causes higher carbon emissions during extraction and manufacturing. Choosing copper clad alternatives can significantly enhance sustainability by minimizing raw material depletion and reducing the ecological footprint linked to copper production.

Choosing the Right Copper Material

Choosing the right copper material depends on your project requirements, with copper clad offering cost-effective durability and solid copper providing superior conductivity and corrosion resistance. Copper clad combines a core metal with a copper layer, making it suitable for applications where weight and budget are concerns. Solid copper is preferred in electrical wiring and plumbing due to its exceptional heat and electrical conductivity, ensuring long-term reliability.

Copper Clad vs Solid Copper Infographic

materialdif.com

materialdif.com