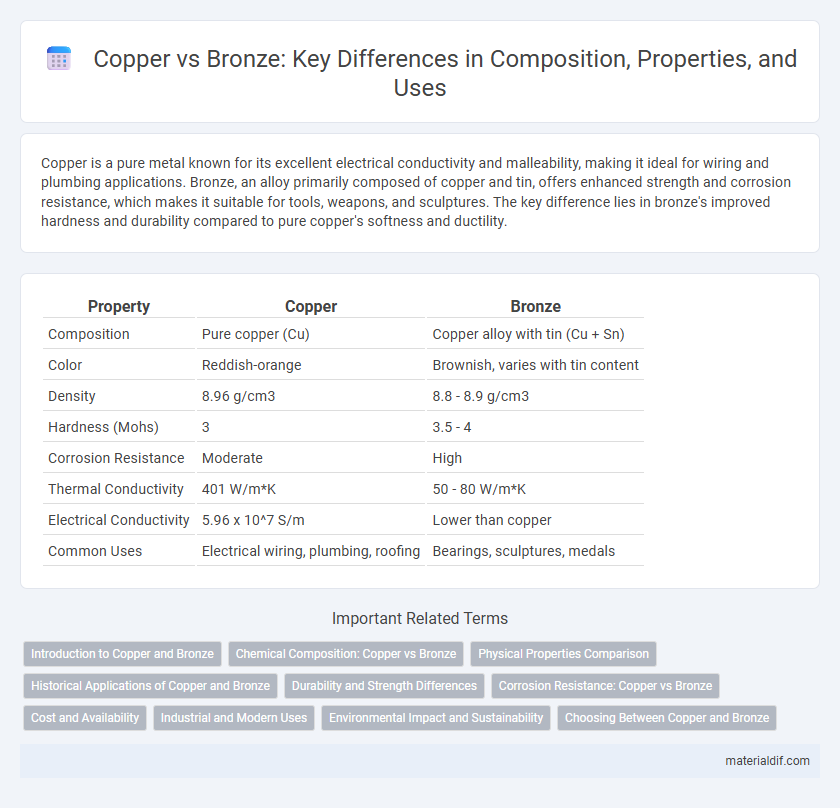

Copper is a pure metal known for its excellent electrical conductivity and malleability, making it ideal for wiring and plumbing applications. Bronze, an alloy primarily composed of copper and tin, offers enhanced strength and corrosion resistance, which makes it suitable for tools, weapons, and sculptures. The key difference lies in bronze's improved hardness and durability compared to pure copper's softness and ductility.

Table of Comparison

| Property | Copper | Bronze |

|---|---|---|

| Composition | Pure copper (Cu) | Copper alloy with tin (Cu + Sn) |

| Color | Reddish-orange | Brownish, varies with tin content |

| Density | 8.96 g/cm3 | 8.8 - 8.9 g/cm3 |

| Hardness (Mohs) | 3 | 3.5 - 4 |

| Corrosion Resistance | Moderate | High |

| Thermal Conductivity | 401 W/m*K | 50 - 80 W/m*K |

| Electrical Conductivity | 5.96 x 10^7 S/m | Lower than copper |

| Common Uses | Electrical wiring, plumbing, roofing | Bearings, sculptures, medals |

Introduction to Copper and Bronze

Copper is a ductile metal known for its excellent electrical and thermal conductivity, while bronze is an alloy primarily made of copper and tin, offering enhanced strength and corrosion resistance. Copper's natural reddish color distinguishes it from bronze's typically darker, more muted tones. Historically, copper was used for tools and ornaments before the Bronze Age marked the development of bronze for more durable and versatile applications.

Chemical Composition: Copper vs Bronze

Copper is a pure element with the chemical symbol Cu and atomic number 29, consisting entirely of copper atoms. Bronze is an alloy primarily composed of copper, usually 88-95%, combined with tin, typically 5-12%, and sometimes other elements like phosphorus or aluminum to enhance strength and corrosion resistance. The presence of tin in bronze alters its chemical composition and physical properties, making it harder and more durable than pure copper.

Physical Properties Comparison

Copper exhibits higher electrical and thermal conductivity compared to bronze, making it more efficient for electrical applications. Bronze, an alloy of copper and tin, offers greater hardness and tensile strength, enhancing its durability in mechanical and structural uses. The density of copper is approximately 8.96 g/cm3, while bronze varies between 7.4 to 8.9 g/cm3 depending on its composition.

Historical Applications of Copper and Bronze

Copper, one of the earliest metals used by humans, played a crucial role in ancient civilizations for tools, weapons, and ornamental objects due to its natural occurrence and malleability. Bronze, an alloy of copper and tin, emerged around 3300 BCE, revolutionizing metallurgy by offering greater hardness and durability, which enhanced the efficiency of tools, armory, and construction materials. The Bronze Age marked a significant technological advancement, with bronze artifacts dominating archaeological records in comparison to the earlier pure copper tools.

Durability and Strength Differences

Copper exhibits lower durability and strength compared to bronze, an alloy typically composed of copper and tin. Bronze's alloy composition enhances its hardness and resistance to corrosion, making it significantly stronger and more durable for industrial and decorative applications. This improvement in mechanical properties positions bronze as a preferred material over pure copper in structural and tool-making contexts.

Corrosion Resistance: Copper vs Bronze

Copper exhibits excellent corrosion resistance, particularly in atmospheric and water environments, forming a protective oxide layer that inhibits further degradation. Bronze, an alloy primarily of copper and tin, often demonstrates improved resistance to corrosion in marine and harsh chemical environments due to the synergistic effects of its alloying elements. This enhanced longevity makes bronze preferable for applications requiring durable materials exposed to seawater or aggressive conditions.

Cost and Availability

Copper, primarily composed of pure copper, is generally more expensive than bronze, an alloy mostly consisting of copper and tin, due to its higher purity and demand in electrical applications. Bronze is often more readily available and cost-effective for manufacturing and artistic purposes because it can be produced using recycled materials and less-refined copper. The fluctuating global copper supply caused by mining challenges directly impacts its price, whereas bronze's diverse composition stabilizes its availability and cost.

Industrial and Modern Uses

Copper is widely utilized in electrical wiring, plumbing, and renewable energy systems due to its excellent conductivity and corrosion resistance, making it essential for modern industrial applications. Bronze, an alloy of copper and tin, offers greater hardness and wear resistance, making it preferable for marine hardware, bearings, and sculptures. While copper dominates electrical and thermal applications, bronze remains critical for mechanical components requiring durability and resistance to friction.

Environmental Impact and Sustainability

Copper mining consumes significant energy and generates sulfur dioxide emissions, contributing to environmental concerns, but copper is highly recyclable, reducing the need for new extraction. Bronze, an alloy primarily of copper and tin, shares similar extraction impacts, although tin mining poses additional environmental hazards such as habitat disruption and toxic waste. Prioritizing copper recycling over the processing of raw materials in bronze production enhances sustainability by minimizing resource depletion and reducing greenhouse gas emissions.

Choosing Between Copper and Bronze

Choosing between copper and bronze depends on the specific application requirements, as copper offers excellent electrical and thermal conductivity, while bronze provides superior strength and corrosion resistance. Bronze, an alloy primarily of copper and tin, is more suitable for heavy-duty mechanical parts and marine hardware due to its durability. Copper is preferred for electrical wiring and plumbing where conductivity and malleability are critical.

Copper vs Bronze Infographic

materialdif.com

materialdif.com