Tin plating offers excellent solderability and corrosion resistance, making it ideal for electronic components and connectors, while nickel plating provides superior hardness and wear resistance, often used for mechanical parts and decorative finishes. Tin plating is more cost-effective and provides a bright, smooth finish, whereas nickel plating delivers a tougher, more durable surface with greater oxidation resistance. Both coatings enhance copper's performance, but the choice depends on whether the application prioritizes electrical conductivity and ease of soldering or mechanical strength and longevity.

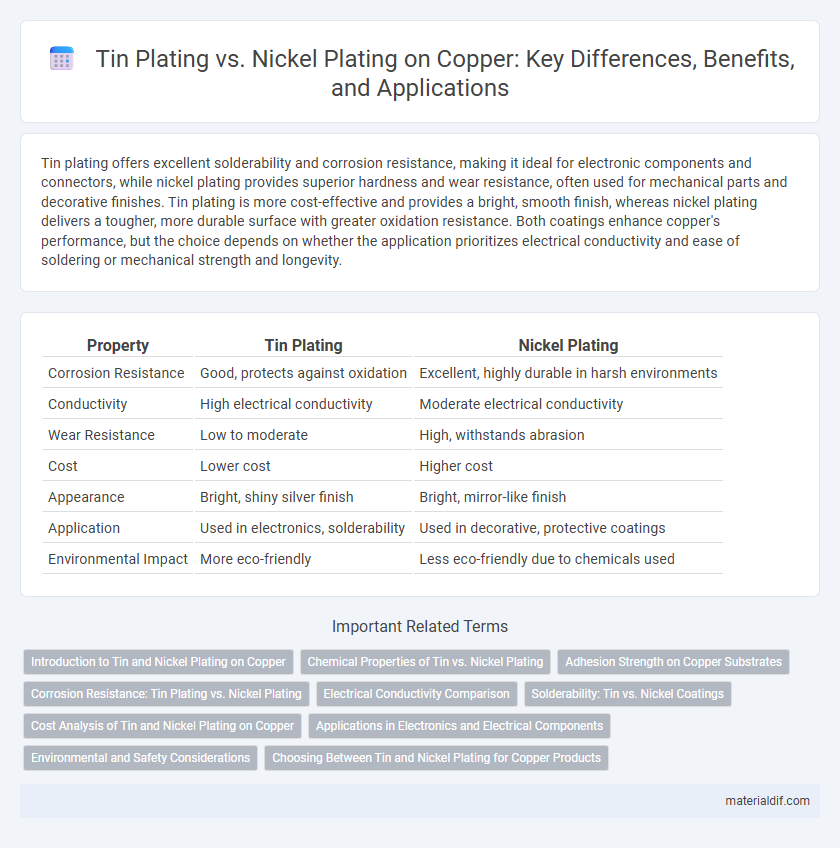

Table of Comparison

| Property | Tin Plating | Nickel Plating |

|---|---|---|

| Corrosion Resistance | Good, protects against oxidation | Excellent, highly durable in harsh environments |

| Conductivity | High electrical conductivity | Moderate electrical conductivity |

| Wear Resistance | Low to moderate | High, withstands abrasion |

| Cost | Lower cost | Higher cost |

| Appearance | Bright, shiny silver finish | Bright, mirror-like finish |

| Application | Used in electronics, solderability | Used in decorative, protective coatings |

| Environmental Impact | More eco-friendly | Less eco-friendly due to chemicals used |

Introduction to Tin and Nickel Plating on Copper

Tin plating on copper enhances corrosion resistance and solderability, making it ideal for electrical components and cookware applications. Nickel plating provides superior hardness and wear resistance, extending the durability of copper parts in industrial environments. Both plating methods improve surface properties but are selected based on performance requirements and cost considerations.

Chemical Properties of Tin vs. Nickel Plating

Tin plating offers excellent corrosion resistance due to its stable oxide layer, which protects underlying copper from oxidation and preserves electrical conductivity. Nickel plating provides superior hardness and wear resistance, forming a dense, chemically inert barrier that withstands harsh environments and prevents copper corrosion. The difference in chemical reactivity means tin resists solderability issues, while nickel plating excels in durability and chemical inertness.

Adhesion Strength on Copper Substrates

Tin plating on copper substrates provides superior adhesion strength due to its excellent metallurgical compatibility, promoting strong intermetallic bonding that enhances corrosion resistance. Nickel plating offers a robust barrier layer but may exhibit less adhesion compared to tin because of potential diffusion and stress at the interface with copper. Optimizing plating parameters can improve adhesion in both cases, but tin plating typically ensures better mechanical stability on copper surfaces.

Corrosion Resistance: Tin Plating vs. Nickel Plating

Tin plating offers excellent corrosion resistance in mildly corrosive environments due to its softness and ability to create a uniform protective layer on copper surfaces. Nickel plating provides superior corrosion protection in harsher and high-temperature environments because of its hardness and dense microstructure, which acts as a robust barrier against oxidation and chemical attack. Copper components coated with nickel plating demonstrate enhanced durability and longer service life compared to tin plating when exposed to aggressive atmospheres or mechanical wear.

Electrical Conductivity Comparison

Tin plating offers superior electrical conductivity compared to nickel plating, making it ideal for applications requiring efficient signal transmission and minimal resistance. Nickel plating provides excellent corrosion resistance and durability but at the cost of reduced conductivity, which can impact performance in sensitive electronic components. Choosing between tin and nickel plating depends on balancing conductivity needs against environmental protection requirements in copper-based electrical systems.

Solderability: Tin vs. Nickel Coatings

Tin plating on copper offers superior solderability due to its excellent wetting properties and low melting point, ensuring strong, reliable joints in electronic assemblies. Nickel plating, while providing enhanced corrosion resistance and durability, can hinder solder flow and requires additional underlayers such as a thin tin finish for optimal solderability. The choice between tin and nickel coatings significantly impacts manufacturing efficiency and long-term performance in PCB and electronic component applications.

Cost Analysis of Tin and Nickel Plating on Copper

Tin plating on copper offers a cost-effective solution due to lower material prices and simpler processing compared to nickel plating. Nickel plating provides superior corrosion resistance and durability but involves higher costs from expensive raw materials and complex electroplating techniques. Evaluating total expenses reveals tin plating as advantageous for budget-sensitive applications, while nickel plating suits projects demanding enhanced longevity despite increased expenditure.

Applications in Electronics and Electrical Components

Tin plating on copper is widely used in electronics for its excellent solderability and corrosion resistance, making it ideal for printed circuit boards and connectors. Nickel plating provides superior wear resistance and durability, frequently applied in electrical contacts and switches where long-term reliability is critical. Both coatings enhance copper's performance, with tin favored for ease of assembly and nickel preferred for harsh environmental conditions.

Environmental and Safety Considerations

Tin plating on copper offers superior environmental benefits due to its non-toxic nature and recyclability, reducing hazardous waste compared to nickel plating, which involves toxic chemicals and poses higher health risks during application. Nickel plating requires strict handling protocols to mitigate exposure to carcinogenic compounds and heavy metals, increasing workplace safety concerns. Choosing tin plating enhances sustainable practices by minimizing environmental contamination and safeguarding worker health in metal finishing processes.

Choosing Between Tin and Nickel Plating for Copper Products

Selecting between tin plating and nickel plating for copper products depends on factors such as corrosion resistance, conductivity, and cost. Tin plating offers excellent solderability and is cost-effective, making it ideal for electrical components and connectors, while nickel plating provides superior hardness, wear resistance, and corrosion protection, suitable for industrial applications exposed to harsh environments. Evaluating the specific requirements of the copper product's application ensures optimal performance and longevity.

Tin Plating vs Nickel Plating Infographic

materialdif.com

materialdif.com