Copper clad steel combines the strength of a steel core with the excellent conductivity and corrosion resistance of a copper outer layer, making it ideal for applications requiring both durability and electrical performance. Solid copper offers superior conductivity and flexibility, which is essential for high-performance electrical systems and intricate wiring projects. Choosing between copper clad steel and solid copper depends on the specific requirements for strength, conductivity, and cost-effectiveness in the intended application.

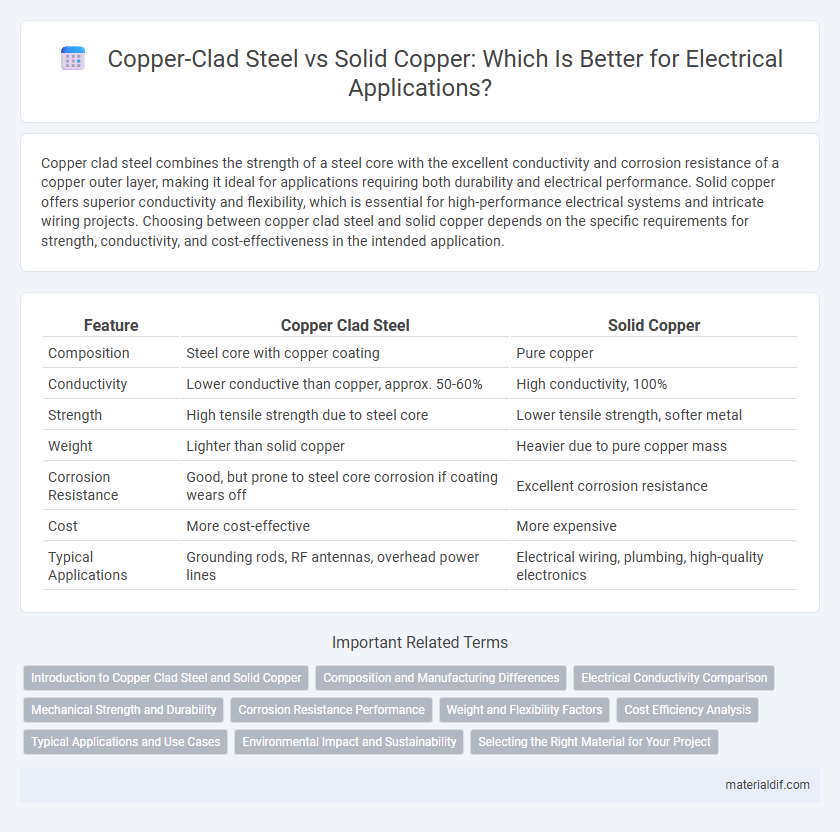

Table of Comparison

| Feature | Copper Clad Steel | Solid Copper |

|---|---|---|

| Composition | Steel core with copper coating | Pure copper |

| Conductivity | Lower conductive than copper, approx. 50-60% | High conductivity, 100% |

| Strength | High tensile strength due to steel core | Lower tensile strength, softer metal |

| Weight | Lighter than solid copper | Heavier due to pure copper mass |

| Corrosion Resistance | Good, but prone to steel core corrosion if coating wears off | Excellent corrosion resistance |

| Cost | More cost-effective | More expensive |

| Typical Applications | Grounding rods, RF antennas, overhead power lines | Electrical wiring, plumbing, high-quality electronics |

Introduction to Copper Clad Steel and Solid Copper

Copper clad steel combines a steel core with a copper outer layer, offering enhanced tensile strength and corrosion resistance while maintaining electrical conductivity. Solid copper consists entirely of copper, providing superior conductivity and excellent corrosion resistance, making it ideal for electrical and thermal applications. The choice between copper clad steel and solid copper depends on balancing mechanical strength with electrical performance requirements.

Composition and Manufacturing Differences

Copper clad steel consists of a steel core coated with a thin layer of copper, combining the strength of steel with the conductivity and corrosion resistance of copper. Solid copper is composed entirely of copper, offering superior electrical and thermal conductivity but less tensile strength compared to copper clad steel. Manufacturing copper clad steel involves a plating or cladding process to bond the copper layer to the steel core, while solid copper is produced through melting and casting or extrusion of pure copper.

Electrical Conductivity Comparison

Copper clad steel exhibits lower electrical conductivity than solid copper due to the steel core's higher resistance, making solid copper the preferred choice for applications requiring maximum conductivity. Solid copper provides superior current flow and minimizes power loss, with conductivity approximately 100% IACS (International Annealed Copper Standard), whereas copper clad steel typically ranges between 20-40% IACS. The trade-off for copper clad steel lies in its enhanced mechanical strength and cost efficiency, but electric engineers favor solid copper for critical electrical conductivity performance.

Mechanical Strength and Durability

Copper Clad Steel (CCS) offers superior mechanical strength compared to solid copper due to its steel core, making it more resistant to bending, stretching, and impact. While solid copper provides excellent electrical conductivity, CCS combines adequate conductivity with enhanced durability and tensile strength, ideal for applications requiring both strength and corrosion resistance. The steel core in CCS significantly extends the lifespan of cables and wires under mechanical stress and harsh environmental conditions.

Corrosion Resistance Performance

Copper clad steel exhibits enhanced mechanical strength but typically offers lower corrosion resistance compared to solid copper, which naturally forms a protective oxide layer that prevents further oxidation. Solid copper's superior corrosion resistance makes it ideal for environments exposed to moisture, chemicals, and atmospheric pollutants. The steel core in copper clad steel may be prone to rust once the copper layer is compromised, reducing its long-term durability in corrosive conditions.

Weight and Flexibility Factors

Copper clad steel combines a steel core with a thin outer layer of copper, resulting in a material that is significantly lighter than solid copper while maintaining moderate flexibility. Solid copper offers superior flexibility and conductivity but is heavier, impacting ease of installation and handling in applications requiring frequent bending. The choice between copper clad steel and solid copper depends on balancing the need for weight reduction against the necessity for maximum flexibility in specific electrical and structural uses.

Cost Efficiency Analysis

Copper clad steel offers a cost-effective alternative to solid copper by combining a steel core with a copper outer layer, significantly reducing material expenses while maintaining adequate conductivity for many applications. The lower price of copper clad steel makes it ideal for large-scale projects or where budget constraints are critical, although it has higher resistance and less corrosion resistance compared to solid copper. Solid copper, while more expensive, provides superior electrical performance and durability, making it suitable for demanding environments requiring long-term reliability.

Typical Applications and Use Cases

Copper clad steel combines the conductivity of copper with the strength of steel, making it ideal for grounding systems, telecommunications cables, and overhead power lines where durability and cost-efficiency are critical. Solid copper, known for its superior conductivity and corrosion resistance, is typically used in electrical wiring, plumbing, and electronic components requiring high performance and reliability. Both materials serve distinct roles, with copper clad steel favored in structural and outdoor environments, while solid copper excels in applications demanding optimal electrical and thermal properties.

Environmental Impact and Sustainability

Copper clad steel offers a smaller environmental footprint than solid copper due to its use of less pure copper, reducing mining demand and energy consumption. Solid copper, while more recyclable and corrosion-resistant, involves extensive extraction processes that contribute to habitat disruption and higher emissions. Choosing copper clad steel supports sustainable resource use by prioritizing material efficiency and lowering overall environmental impact.

Selecting the Right Material for Your Project

Copper clad steel combines the strength of steel with the conductivity of copper, making it ideal for telecommunications and grounding applications where durability and electrical performance are paramount. Solid copper offers superior electrical conductivity and corrosion resistance, preferred for high-frequency signal transmission and plumbing systems requiring long-term reliability. Selecting between copper clad steel and solid copper depends on balancing mechanical strength, conductivity needs, and budget constraints specific to your project requirements.

Copper Clad Steel vs Solid Copper Infographic

materialdif.com

materialdif.com