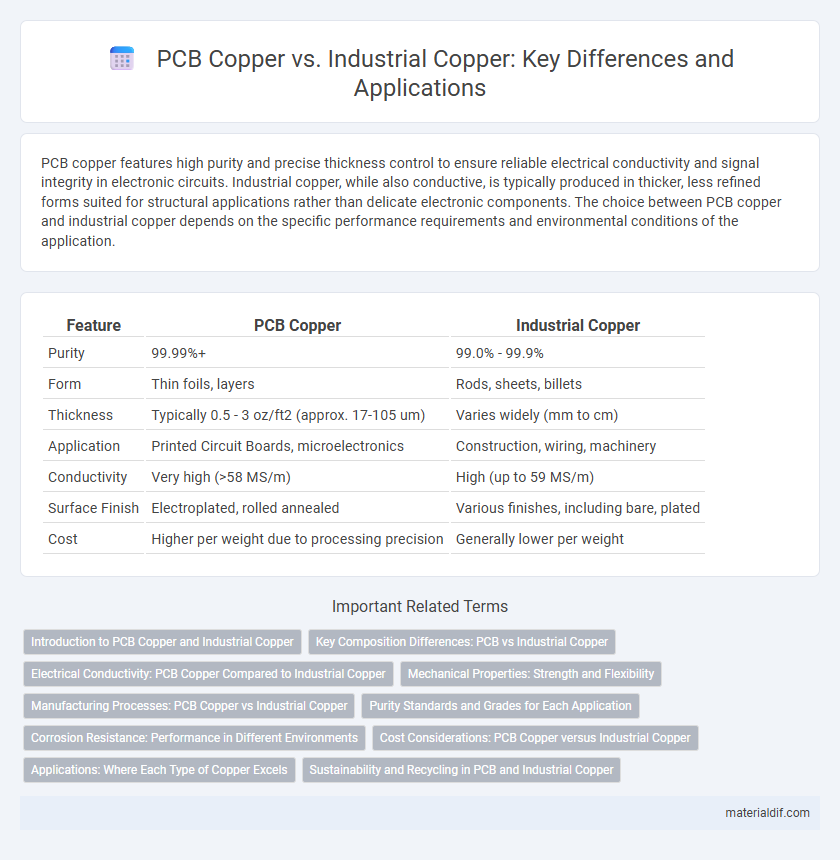

PCB copper features high purity and precise thickness control to ensure reliable electrical conductivity and signal integrity in electronic circuits. Industrial copper, while also conductive, is typically produced in thicker, less refined forms suited for structural applications rather than delicate electronic components. The choice between PCB copper and industrial copper depends on the specific performance requirements and environmental conditions of the application.

Table of Comparison

| Feature | PCB Copper | Industrial Copper |

|---|---|---|

| Purity | 99.99%+ | 99.0% - 99.9% |

| Form | Thin foils, layers | Rods, sheets, billets |

| Thickness | Typically 0.5 - 3 oz/ft2 (approx. 17-105 um) | Varies widely (mm to cm) |

| Application | Printed Circuit Boards, microelectronics | Construction, wiring, machinery |

| Conductivity | Very high (>58 MS/m) | High (up to 59 MS/m) |

| Surface Finish | Electroplated, rolled annealed | Various finishes, including bare, plated |

| Cost | Higher per weight due to processing precision | Generally lower per weight |

Introduction to PCB Copper and Industrial Copper

PCB copper is a highly conductive material specifically engineered for printed circuit boards, featuring ultra-thin copper foils that enable precise electrical pathways and signal integrity in electronic devices. Industrial copper, in contrast, encompasses a broader range of copper grades used in manufacturing, construction, and heavy industry, characterized by thicker gauges and enhanced mechanical strength. The key distinction lies in PCB copper's refined purity and controlled thickness tailored for microelectronics, whereas industrial copper prioritizes durability and conductivity for large-scale applications.

Key Composition Differences: PCB vs Industrial Copper

PCB copper typically contains a higher purity level, often above 99.9% copper, to ensure excellent electrical conductivity and minimal signal loss in electronic circuits. Industrial copper grades may include added elements like silver, zinc, or tin to enhance mechanical strength, corrosion resistance, and durability for heavy-duty applications. The key composition difference lies in the stringent purity requirements for PCB copper versus the alloying focus in industrial copper to meet diverse manufacturing demands.

Electrical Conductivity: PCB Copper Compared to Industrial Copper

PCB copper typically exhibits higher electrical conductivity than industrial copper due to its superior purity and refined grain structure, which minimizes electron scattering. Industrial copper often contains alloying elements and impurities that reduce its conductivity by increasing resistance. This enhanced electrical performance makes PCB copper ideal for high-frequency and low-loss circuit applications.

Mechanical Properties: Strength and Flexibility

PCB copper exhibits higher flexibility and moderate strength, tailored for thin, tightly bent circuit board applications where reliable electrical conductivity and mechanical endurance are critical. Industrial copper, in contrast, often possesses greater tensile strength and hardness due to alloying and processing variations, making it suitable for heavy-duty structural and mechanical uses. Understanding these mechanical properties ensures optimal material selection for specific engineering demands in electronics versus industrial manufacturing.

Manufacturing Processes: PCB Copper vs Industrial Copper

PCB copper undergoes precise electroplating and etching processes to form thin, uniform layers essential for intricate circuit patterns, ensuring high conductivity and reliability in electronic components. Industrial copper, in contrast, is produced through large-scale smelting and casting techniques that create bulk copper materials such as rods, sheets, and wires for construction, electrical, and manufacturing applications. The manufacturing processes for PCB copper emphasize fine detail and purity control, while industrial copper processes focus on mass production and mechanical strength.

Purity Standards and Grades for Each Application

PCB copper typically requires ultra-high purity levels, often exceeding 99.99%, to ensure optimal electrical conductivity and minimal signal loss in electronic circuits. Industrial copper used in construction or manufacturing may have lower purity standards, around 99.5% to 99.9%, as slight impurities do not significantly impact structural strength or thermal applications. These differing purity grades are critical to meeting the specific performance and reliability demands of each application.

Corrosion Resistance: Performance in Different Environments

PCB copper exhibits superior corrosion resistance due to its high purity and specialized surface treatments, making it ideal for delicate electronic circuits exposed to humid or chemically aggressive environments. Industrial copper, while robust and versatile, often contains alloying elements that can reduce corrosion resistance but enhance mechanical strength for structural applications. In environments with frequent exposure to corrosive agents, PCB copper maintains conductivity and integrity longer, whereas industrial copper may require protective coatings or maintenance to prevent degradation.

Cost Considerations: PCB Copper versus Industrial Copper

PCB copper typically costs more per unit weight than industrial copper due to its higher purity and specialized processing requirements for electronics manufacturing. Industrial copper, often used in bulk for construction or electrical wiring, benefits from economies of scale and less stringent purity standards, resulting in lower overall costs. Choosing between PCB copper and industrial copper depends on balancing cost efficiency against performance demands in specific applications.

Applications: Where Each Type of Copper Excels

PCB copper excels in electronics manufacturing due to its high conductivity and precise thickness control, enabling reliable signal transmission on printed circuit boards. Industrial copper is preferred in heavy-duty applications such as electrical wiring, plumbing, and heat exchangers, where durability and corrosion resistance are critical. The choice between PCB copper and industrial copper depends on application-specific requirements like conductivity, mechanical strength, and environmental exposure.

Sustainability and Recycling in PCB and Industrial Copper

PCB copper features high recyclability rates due to its thin layers and frequent reuse in electronic waste recycling programs, significantly reducing environmental impact compared to industrial copper. Industrial copper, while larger in volume, presents challenges in sustainability because its extraction and processing consume more energy and generate higher emissions. Advances in closed-loop recycling and environmentally-friendly refining techniques are essential in both sectors to enhance copper sustainability and minimize resource depletion.

PCB Copper vs Industrial Copper Infographic

materialdif.com

materialdif.com