Copper powder offers a finer particle size that enhances reactivity and uniformity in applications like metallurgy and electronics, while copper granules provide larger, coarser particles suited for easier handling and slower dissolution rates. The choice between copper powder and granules depends on the specific use case, with powder preferred for rapid chemical reactions and granules favored for controlled processing. Both forms deliver high conductivity and corrosion resistance, essential for electrical and industrial uses.

Table of Comparison

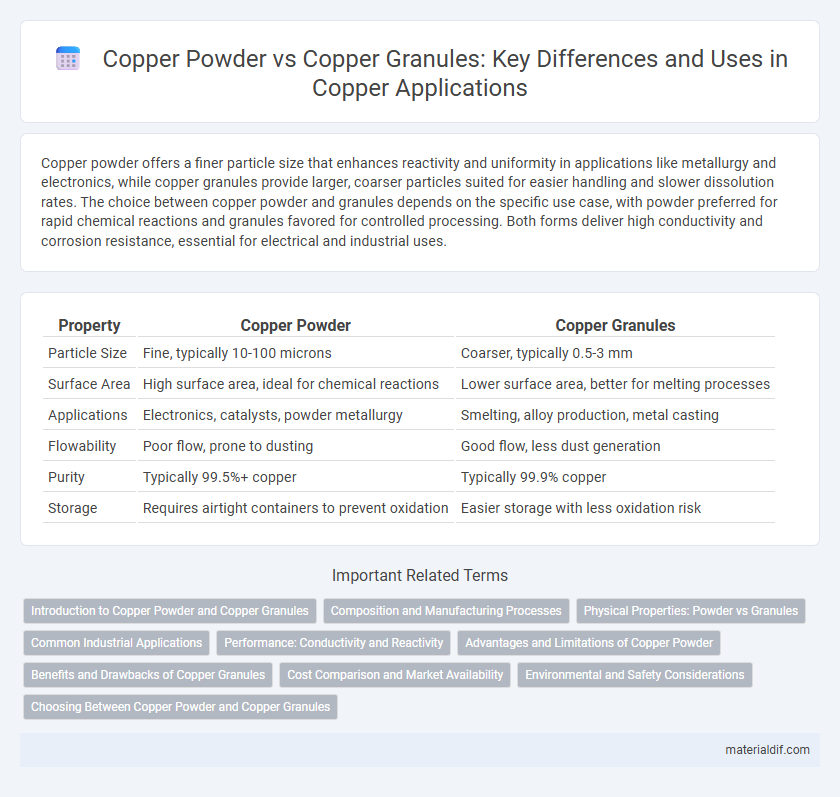

| Property | Copper Powder | Copper Granules |

|---|---|---|

| Particle Size | Fine, typically 10-100 microns | Coarser, typically 0.5-3 mm |

| Surface Area | High surface area, ideal for chemical reactions | Lower surface area, better for melting processes |

| Applications | Electronics, catalysts, powder metallurgy | Smelting, alloy production, metal casting |

| Flowability | Poor flow, prone to dusting | Good flow, less dust generation |

| Purity | Typically 99.5%+ copper | Typically 99.9% copper |

| Storage | Requires airtight containers to prevent oxidation | Easier storage with less oxidation risk |

Introduction to Copper Powder and Copper Granules

Copper powder consists of finely divided particles that offer high surface area and are commonly used in powder metallurgy and conductive applications. Copper granules are larger, irregularly shaped particles that provide better flow characteristics and are favored in processes requiring easy handling and consistent melting behavior. Both forms serve distinct industrial needs, with powders preferred for precision and granules for bulk applications.

Composition and Manufacturing Processes

Copper powder consists of fine particles produced primarily through atomization or chemical reduction, resulting in high purity and uniform particle size essential for powder metallurgy and additive manufacturing. Copper granules are larger aggregates formed by casting or granulation techniques, characterized by a coarser texture and often used in applications requiring easier handling and slower dissolution. The composition in both forms remains predominantly pure copper, but manufacturing processes influence particle morphology and surface characteristics, affecting their suitability for specific industrial applications.

Physical Properties: Powder vs Granules

Copper powder consists of fine, irregular particles with high surface area, enabling faster reactions and better sintering properties compared to copper granules, which are larger, more uniform, and have lower surface area. The density of copper powder is typically lower than that of granules due to the increased porosity and interstitial spaces between the fine particles. Copper granules provide improved flowability and reduced dust formation, making them preferable for handling and storage in industrial applications where physical stability is critical.

Common Industrial Applications

Copper powder and copper granules serve distinct purposes in industrial applications; copper powder is ideal for additive manufacturing, powder metallurgy, and conductive inks due to its fine particle size and high surface area. Copper granules, being coarser, are commonly used in alloy production, brazing, and melting processes where rapid melting and uniform heat transfer are essential. Both forms are integral in electronics, chemical industries, and metalworking for enhancing electrical conductivity, corrosion resistance, and thermal properties.

Performance: Conductivity and Reactivity

Copper powder exhibits higher reactivity due to its increased surface area, enhancing its suitability for chemical reactions and catalytic processes. Copper granules possess superior electrical conductivity in bulk form, making them ideal for applications requiring efficient current flow. The choice between copper powder and granules depends on balancing reactivity and conductivity demands in specific industrial uses.

Advantages and Limitations of Copper Powder

Copper powder offers higher surface area and improved reactivity compared to copper granules, making it ideal for applications in catalysts, powders metallurgy, and additive manufacturing. Its fine particle size enables better sintering and uniform distribution in composite materials but also poses challenges such as higher oxidation risk and handling difficulties due to dustiness. While copper granules provide easier handling and lower oxidation rates, they lack the enhanced surface interactions and compactibility that copper powder delivers.

Benefits and Drawbacks of Copper Granules

Copper granules offer benefits such as improved handling and reduced dust generation compared to copper powder, making them safer and easier to store and transport. Their larger particle size allows for better flowability and uniform melting in metallurgical applications but may result in slower reaction rates in chemical processes compared to finer copper powder. However, copper granules have limited surface area, which can reduce their effectiveness in applications requiring high reactivity or rapid oxidation.

Cost Comparison and Market Availability

Copper powder generally commands a higher price than copper granules due to its finer particle size and increased surface area, which enhance reactivity and applications in specialized industries like electronics and additive manufacturing. Copper granules are more widely available and economically favorable for bulk applications such as metal refining and alloy production, benefiting from simpler manufacturing processes. Market availability shows a robust global supply chain for copper granules, particularly in regions with strong mining activities, while copper powder markets remain more niche and are driven by high-tech sectors.

Environmental and Safety Considerations

Copper powder poses higher environmental and safety risks compared to copper granules due to its increased surface area, which makes it more reactive and prone to oxidation and combustion. Copper granules present lower fire hazards and reduced dust generation, minimizing inhalation risks during handling and processing. Proper storage and handling protocols are essential for both forms to prevent environmental contamination and ensure workplace safety.

Choosing Between Copper Powder and Copper Granules

Choosing between copper powder and copper granules depends on application requirements such as surface area, reactivity, and ease of handling. Copper powder offers a higher surface area for faster reactions and is preferred in catalytic processes and sintering applications. Copper granules provide better flowability and reduced dust generation, making them ideal for melting and alloying in metalworking industries.

Copper Powder vs Copper Granules Infographic

materialdif.com

materialdif.com