Oxygenated copper contains small amounts of oxygen, which enhances its strength and hardness, making it ideal for applications requiring improved mechanical properties. Deoxygenated copper is nearly free of oxygen, resulting in higher electrical conductivity and better corrosion resistance, suitable for electrical wiring and plumbing. Understanding the differences between oxygenated and deoxygenated copper helps optimize material selection for specific industrial uses.

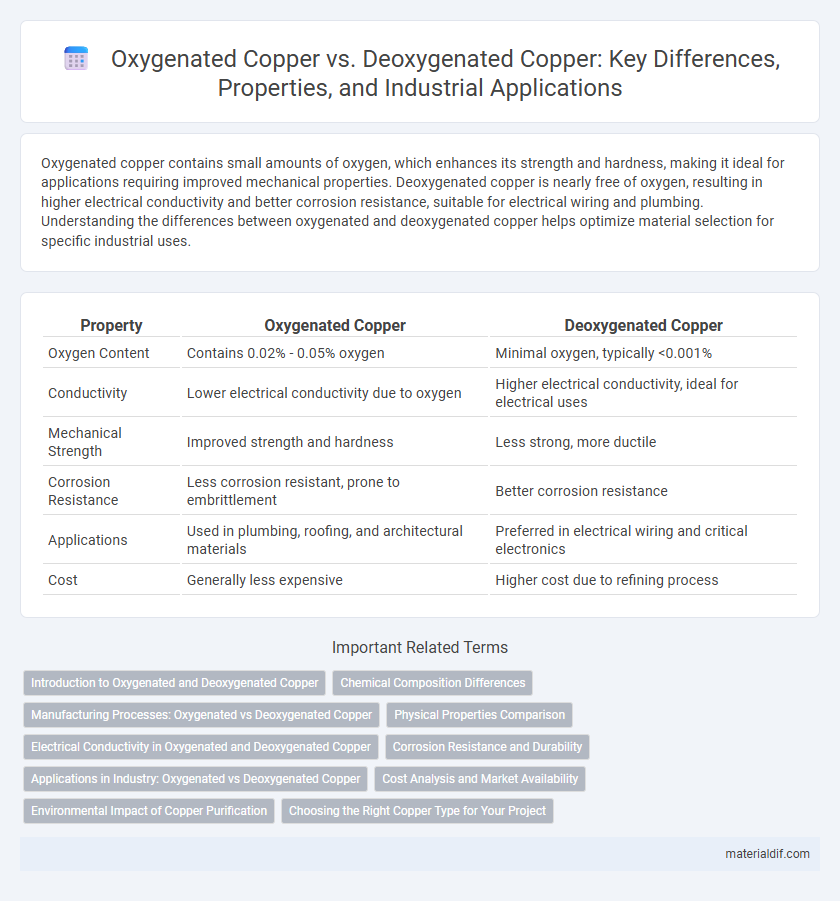

Table of Comparison

| Property | Oxygenated Copper | Deoxygenated Copper |

|---|---|---|

| Oxygen Content | Contains 0.02% - 0.05% oxygen | Minimal oxygen, typically <0.001% |

| Conductivity | Lower electrical conductivity due to oxygen | Higher electrical conductivity, ideal for electrical uses |

| Mechanical Strength | Improved strength and hardness | Less strong, more ductile |

| Corrosion Resistance | Less corrosion resistant, prone to embrittlement | Better corrosion resistance |

| Applications | Used in plumbing, roofing, and architectural materials | Preferred in electrical wiring and critical electronics |

| Cost | Generally less expensive | Higher cost due to refining process |

Introduction to Oxygenated and Deoxygenated Copper

Oxygenated copper contains a small, controlled amount of oxygen, typically around 0.02% to 0.04%, which improves its strength and wear resistance, making it ideal for applications like electrical conductors and automotive components. Deoxygenated copper, also known as oxygen-free copper, has oxygen content reduced to less than 0.001%, offering superior electrical conductivity and enhanced corrosion resistance, suitable for high-performance electrical and electronic uses. The choice between oxygenated and deoxygenated copper is critical depending on the desired mechanical properties and conductivity requirements in industrial applications.

Chemical Composition Differences

Oxygenated copper contains traces of oxygen, typically around 0.02% to 0.04%, which enhances its mechanical strength and conductivity by reducing impurities during refining. Deoxygenated copper, also known as oxygen-free copper, is produced by removing oxygen to levels below 0.001%, resulting in superior electrical and thermal conductivity ideal for high-performance electrical applications. The primary chemical composition difference lies in oxygen content, affecting the copper's microstructure and overall physical properties.

Manufacturing Processes: Oxygenated vs Deoxygenated Copper

Oxygenated copper is produced by adding oxygen during the smelting process, which helps remove impurities and improve the metal's hardness and strength. Deoxygenated copper, also known as oxygen-free copper, undergoes refining methods like fire refining or electrolysis to eliminate oxygen content, enhancing electrical conductivity and resistance to hydrogen embrittlement. Manufacturing processes for oxygenated copper are generally more cost-effective but result in lower purity, whereas deoxygenated copper requires more complex refining steps to achieve higher purity levels critical for electronic and high-performance applications.

Physical Properties Comparison

Oxygenated copper contains controlled amounts of oxygen, typically around 0.02% to 0.04%, which enhances its tensile strength and wear resistance compared to deoxygenated copper that has oxygen levels below 0.001%. The presence of oxygen in oxygenated copper improves creep resistance and hardness but reduces electrical conductivity slightly relative to deoxygenated copper, which is more ductile and better suited for electrical applications. Deoxygenated copper exhibits higher purity and superior corrosion resistance, making it preferable for critical electrical components requiring consistent conductivity and flexibility.

Electrical Conductivity in Oxygenated and Deoxygenated Copper

Oxygenated copper typically contains a small amount of oxygen, which forms fine copper oxides that improve its mechanical strength but slightly reduce electrical conductivity compared to deoxygenated copper. Deoxygenated copper has had oxygen removed during refining, resulting in higher electrical conductivity, often exceeding 100% IACS (International Annealed Copper Standard), making it ideal for electrical applications requiring maximum conductivity. The difference in oxygen content directly affects the purity and microstructure, with deoxygenated copper preferred in high-performance conductors due to its superior electrical performance.

Corrosion Resistance and Durability

Oxygenated copper contains a small amount of oxygen, improving its corrosion resistance by forming a protective oxide layer that enhances durability in harsh environments. Deoxygenated copper, with minimal oxygen content, offers superior electrical conductivity but is more susceptible to corrosion and less durable in aggressive conditions. The choice between oxygenated and deoxygenated copper depends on the required balance between corrosion resistance and electrical performance for specific applications.

Applications in Industry: Oxygenated vs Deoxygenated Copper

Oxygenated copper, containing trace amounts of oxygen, is favored in electrical applications such as wiring and transformer windings due to its enhanced tensile strength and resistance to hydrogen embrittlement. Deoxygenated copper, often purified by phosphorus deoxidation, is preferred in plumbing, roofing, and chemical processing industries because of its superior corrosion resistance and improved ductility. Selection between oxygenated and deoxygenated copper depends on specific industrial requirements, balancing mechanical properties and environmental durability.

Cost Analysis and Market Availability

Oxygenated copper generally incurs higher production costs due to the inclusion of precise oxygen control during smelting, resulting in improved strength and resistance to hydrogen embrittlement, which justifies its premium pricing in specialized applications. Deoxygenated copper, often produced by casting in reducing atmospheres or by adding deoxidizers like phosphorus, is more widely available and favored for standard electrical and plumbing uses, reflecting its cost-effectiveness and abundant supply in the global market. Cost analysis reveals that while oxygenated copper commands a niche market segment with value-added properties, deoxygenated copper dominates large-scale commodity markets due to lower processing expenses and broader distribution channels.

Environmental Impact of Copper Purification

Oxygenated copper contains small amounts of oxygen that enhance its ductility and welding properties, reducing energy consumption during manufacturing and minimizing waste. Deoxygenated copper, produced through refinements like the Mitsui or Houghton processes, lowers impurities but often requires more intensive treatments, increasing energy use and environmental emissions. Selecting oxygenated copper can lead to a lower overall environmental footprint by optimizing purification efficiency and decreasing harmful byproducts.

Choosing the Right Copper Type for Your Project

Oxygenated copper contains trace amounts of oxygen, enhancing its strength and resistance to stress, making it ideal for electrical wiring and structural applications where durability is essential. Deoxygenated copper, with minimal oxygen content, offers superior conductivity and improved corrosion resistance, making it suitable for sensitive electronic components and high-purity environments. Selecting the right copper type depends on the specific requirements of conductivity, mechanical strength, and environmental conditions of your project.

Oxygenated Copper vs Deoxygenated Copper Infographic

materialdif.com

materialdif.com