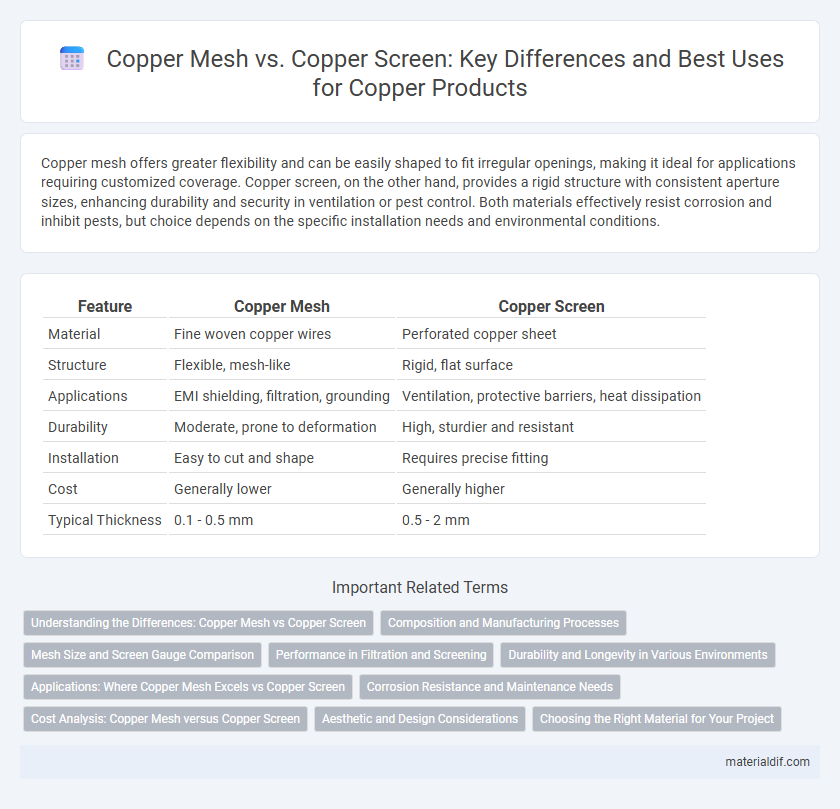

Copper mesh offers greater flexibility and can be easily shaped to fit irregular openings, making it ideal for applications requiring customized coverage. Copper screen, on the other hand, provides a rigid structure with consistent aperture sizes, enhancing durability and security in ventilation or pest control. Both materials effectively resist corrosion and inhibit pests, but choice depends on the specific installation needs and environmental conditions.

Table of Comparison

| Feature | Copper Mesh | Copper Screen |

|---|---|---|

| Material | Fine woven copper wires | Perforated copper sheet |

| Structure | Flexible, mesh-like | Rigid, flat surface |

| Applications | EMI shielding, filtration, grounding | Ventilation, protective barriers, heat dissipation |

| Durability | Moderate, prone to deformation | High, sturdier and resistant |

| Installation | Easy to cut and shape | Requires precise fitting |

| Cost | Generally lower | Generally higher |

| Typical Thickness | 0.1 - 0.5 mm | 0.5 - 2 mm |

Understanding the Differences: Copper Mesh vs Copper Screen

Copper mesh features a woven pattern of fine copper wires, providing high flexibility and excellent filtration for applications like electromagnetic shielding and pest control. Copper screen, typically made from thicker strands with a more rigid construction, excels in durability and structural support for industrial sieving and ventilation purposes. Understanding these differences helps select the optimal copper material based on filtration precision, mechanical strength, and specific application requirements.

Composition and Manufacturing Processes

Copper mesh consists of woven copper wires creating a flexible grid, while copper screen typically features finer, tightly woven copper strands for enhanced filtration. The manufacturing process of copper mesh involves wire drawing followed by weaving or knitting to form an open fabric, whereas copper screen undergoes precise weaving with thinner gauge wires for uniform apertures. Both products maintain high copper purity, often exceeding 99.9%, ensuring excellent conductivity and corrosion resistance in various industrial applications.

Mesh Size and Screen Gauge Comparison

Copper mesh and copper screen differ primarily in mesh size and screen gauge, which affect their filtration efficiency and application. Copper mesh typically features larger mesh sizes with coarser strands, making it suitable for larger particle filtration, while copper screens have finer mesh sizes and higher screen gauges, providing more precise filtration. The screen gauge in copper products measures the thickness of the wire, with higher gauges indicating thinner wires that yield finer mesh, crucial for demanding industrial and electronic uses.

Performance in Filtration and Screening

Copper mesh offers superior filtration performance due to its tightly woven structure, enabling efficient trapping of fine particles and contaminants. Copper screens provide excellent screening capabilities with larger openings, allowing rapid passage of materials while preventing debris from passing through. In applications requiring high precision filtration, copper mesh is preferred, whereas copper screens excel in coarse screening and airflow regulation.

Durability and Longevity in Various Environments

Copper mesh demonstrates superior durability compared to copper screen due to its thicker, woven strands that resist corrosion and mechanical damage more effectively. In harsh environments with high humidity or chemical exposure, copper mesh maintains structural integrity longer, reducing the need for frequent replacements. Copper screen, while cost-effective, tends to degrade faster under such conditions, limiting its longevity in industrial or outdoor applications.

Applications: Where Copper Mesh Excels vs Copper Screen

Copper mesh excels in applications requiring filtration and EMI shielding due to its fine weave and high conductivity, making it ideal for electronic enclosures and RF interference prevention. Copper screens, with their rigid structure and larger openings, are better suited for protective guards, insect screens, and structural reinforcement in construction. The choice depends on the balance between filtration precision and mechanical strength needed for specific industrial or architectural uses.

Corrosion Resistance and Maintenance Needs

Copper mesh exhibits superior corrosion resistance compared to copper screen due to its thicker and more durable wire structure, which reduces oxidation over time. The mesh's dense weave minimizes exposure to environmental elements, lowering maintenance frequency and extending its lifespan in harsh conditions. Copper screens, with thinner strands and a looser pattern, require more frequent cleaning and replacement to prevent corrosion buildup and maintain functionality.

Cost Analysis: Copper Mesh versus Copper Screen

Copper mesh typically costs less due to its simpler manufacturing process and lower material density compared to copper screen. Copper screen, made from tightly woven fine wire, demands higher production precision and more raw copper, increasing its price. When considering long-term investment, copper screen offers enhanced durability and filtration efficiency, potentially offsetting its initial higher cost.

Aesthetic and Design Considerations

Copper mesh offers a more flexible and organic aesthetic, providing a unique texture that complements rustic and industrial design themes. Copper screens, crafted with precise patterns, deliver a sleek and modern appearance ideal for contemporary architectural applications. Both materials exhibit natural patina over time, enhancing visual appeal while serving as functional decorative elements.

Choosing the Right Material for Your Project

Copper mesh offers greater flexibility and durability for applications requiring comprehensive coverage and easy conformity to irregular shapes, while copper screen provides a more open weave suitable for ventilation and filtration projects. Selecting the right material depends on project-specific needs such as electromagnetic interference shielding, pest control, or filtration efficiency. Evaluating factors like aperture size, conductivity, and mechanical strength helps determine whether copper mesh or copper screen will best enhance performance and longevity.

Copper Mesh vs Copper Screen Infographic

materialdif.com

materialdif.com