Oxygen-free copper (OFC) is highly pure, containing minimal oxygen, which enhances its conductivity and resistance to corrosion, making it ideal for audio, electrical, and industrial applications requiring high performance. Deoxidized copper, also known as tough pitch copper, contains a small amount of oxygen, improving its mechanical properties and ease of welding but reducing electrical conductivity compared to OFC. Choosing between oxygen-free and deoxidized copper depends on the specific requirements for conductivity, strength, and chemical resistance in the intended use.

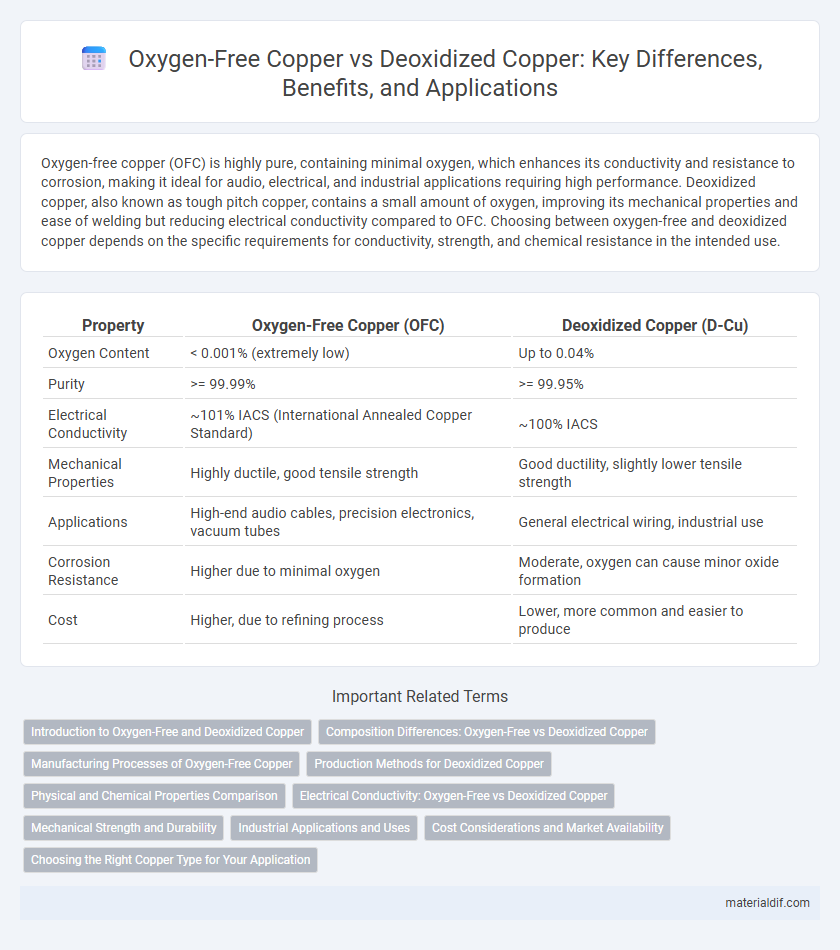

Table of Comparison

| Property | Oxygen-Free Copper (OFC) | Deoxidized Copper (D-Cu) |

|---|---|---|

| Oxygen Content | < 0.001% (extremely low) | Up to 0.04% |

| Purity | >= 99.99% | >= 99.95% |

| Electrical Conductivity | ~101% IACS (International Annealed Copper Standard) | ~100% IACS |

| Mechanical Properties | Highly ductile, good tensile strength | Good ductility, slightly lower tensile strength |

| Applications | High-end audio cables, precision electronics, vacuum tubes | General electrical wiring, industrial use |

| Corrosion Resistance | Higher due to minimal oxygen | Moderate, oxygen can cause minor oxide formation |

| Cost | Higher, due to refining process | Lower, more common and easier to produce |

Introduction to Oxygen-Free and Deoxidized Copper

Oxygen-Free Copper (OFC) is characterized by a purity level exceeding 99.95% with minimal oxygen content, enhancing its electrical conductivity and resistance to corrosion. Deoxidized Copper, also known as oxygen-free electronic (OFE) copper, includes trace amounts of oxygen removed by additives like phosphorus to prevent hydrogen embrittlement during processing. Both types are essential in high-performance electrical applications, with OFC preferred for audio and critical electronics due to superior signal transmission qualities.

Composition Differences: Oxygen-Free vs Deoxidized Copper

Oxygen-Free Copper (OFC) contains less than 0.001% oxygen, achieved through a controlled melting process with minimal exposure to air, resulting in superior electrical conductivity and corrosion resistance. Deoxidized Copper, also known as Oxygen-Removed Copper, typically contains around 0.02% to 0.04% oxygen, as oxygen is removed by adding deoxidizing agents like phosphorus or silicon during melting, which can introduce inclusions affecting purity. The key compositional difference lies in oxygen content and residual impurities, impacting the metal's performance in high-purity applications such as electronics and vacuum environments.

Manufacturing Processes of Oxygen-Free Copper

Oxygen-free copper (OFC) is produced by melting cathode copper under a controlled atmosphere with hydrogen or inert gas to minimize oxygen content below 0.001%, resulting in improved electrical conductivity and corrosion resistance. The manufacturing process includes vacuum refining or electrorefining to eliminate oxygen and impurities, distinguishing it from deoxidized copper where oxygen is removed by adding deoxidizers like phosphorus or silicon during casting. OFC's stringent refining techniques make it ideal for high-performance electrical applications and sensitive electronic components.

Production Methods for Deoxidized Copper

Deoxidized copper is produced by adding deoxidizing agents such as phosphorus, aluminum, or silicon during the melting process to remove oxygen and prevent oxidation. This method contrasts with oxygen-free copper production, which involves melting copper in a controlled, oxygen-free atmosphere to achieve higher purity. The addition of deoxidizers in deoxidized copper enhances its strength and electrical conductivity by reducing oxide inclusions during solidification.

Physical and Chemical Properties Comparison

Oxygen-free copper (OFC) exhibits superior electrical conductivity and enhanced thermal stability compared to deoxidized copper, due to its minimal oxygen content, typically less than 0.001%. Deoxidized copper contains small amounts of oxygen and other impurities that can form oxides, affecting ductility and corrosion resistance. The lower oxygen level in OFC results in reduced hydrogen embrittlement risk and improved mechanical properties, making it ideal for high-performance electrical applications.

Electrical Conductivity: Oxygen-Free vs Deoxidized Copper

Oxygen-Free Copper (OFC) exhibits higher electrical conductivity, typically around 101% IACS (International Annealed Copper Standard), due to its minimal oxygen and impurity content, enhancing signal transmission and reducing resistive losses. Deoxidized Copper, also known as ETP (Electrolytic Tough Pitch), contains small amounts of oxygen, resulting in slightly lower conductivity near 100% IACS, which can affect high-frequency signal performance. The superior purity of Oxygen-Free Copper makes it preferred for critical electrical applications demanding optimal conductivity and longevity.

Mechanical Strength and Durability

Oxygen-Free Copper (OFC) exhibits superior mechanical strength and enhanced durability due to its minimal oxygen content, which reduces the formation of brittle oxides that weaken the metal structure. In contrast, Deoxidized Copper contains higher oxygen levels, leading to increased risk of internal voids and decreased mechanical performance under stress. Consequently, OFC is preferred in applications demanding high reliability and long-term structural integrity.

Industrial Applications and Uses

Oxygen-Free Copper (OFC) offers superior electrical conductivity and corrosion resistance, making it ideal for high-performance electrical wiring, semiconductor substrates, and audio equipment in industrial applications. Deoxidized Copper, containing small amounts of oxygen, is commonly used in plumbing, heat exchangers, and industrial machinery parts due to its improved machinability and reduced risk of hydrogen embrittlement. The choice between Oxygen-Free and Deoxidized Copper depends on the specific industrial use case, balancing conductivity requirements and mechanical properties.

Cost Considerations and Market Availability

Oxygen-Free Copper (OFC) generally commands higher prices due to its superior conductivity and purity, making it ideal for high-performance electrical applications, whereas Deoxidized Copper (DA) offers a more cost-effective alternative with slightly lower conductivity. Market availability of OFC is more limited, often supplied in smaller quantities and specialized grades, while Deoxidized Copper is widely available in bulk for general industrial use. Cost considerations favor Deoxidized Copper for large-scale manufacturing, but OFC remains preferred where electrical performance justifies the premium.

Choosing the Right Copper Type for Your Application

Oxygen-Free Copper (OFC) offers superior electrical conductivity and corrosion resistance, making it ideal for high-performance audio cables and sensitive electronic components. Deoxidized Copper contains controlled oxygen content to improve brazing and welding performance, suitable for applications requiring mechanical strength and durability. Selecting the right copper type depends on the balance between electrical purity and mechanical requirements specific to your project's needs.

Oxygen-Free Copper vs Deoxidized Copper Infographic

materialdif.com

materialdif.com