Copper piping offers durability, resistance to high temperatures, and natural antimicrobial properties, making it ideal for long-lasting plumbing systems. PEX tubing provides flexibility, easier installation, and resistance to corrosion and scale buildup, which reduces maintenance costs. Choosing between copper and PEX depends on budget, climate conditions, and specific plumbing requirements.

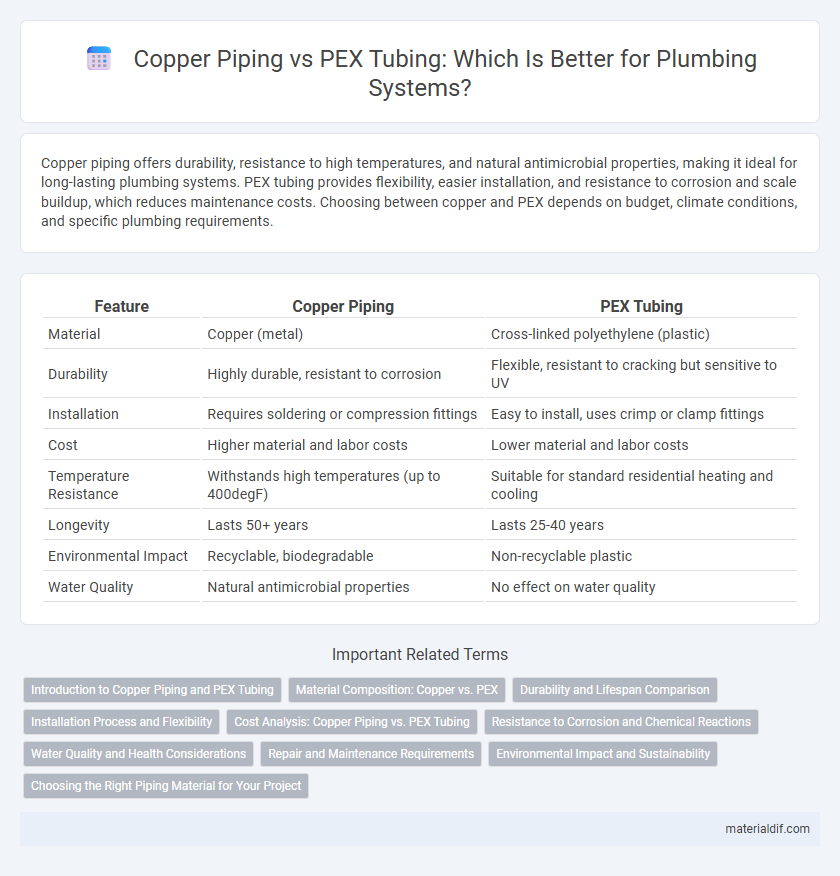

Table of Comparison

| Feature | Copper Piping | PEX Tubing |

|---|---|---|

| Material | Copper (metal) | Cross-linked polyethylene (plastic) |

| Durability | Highly durable, resistant to corrosion | Flexible, resistant to cracking but sensitive to UV |

| Installation | Requires soldering or compression fittings | Easy to install, uses crimp or clamp fittings |

| Cost | Higher material and labor costs | Lower material and labor costs |

| Temperature Resistance | Withstands high temperatures (up to 400degF) | Suitable for standard residential heating and cooling |

| Longevity | Lasts 50+ years | Lasts 25-40 years |

| Environmental Impact | Recyclable, biodegradable | Non-recyclable plastic |

| Water Quality | Natural antimicrobial properties | No effect on water quality |

Introduction to Copper Piping and PEX Tubing

Copper piping, a durable and corrosion-resistant material, has been widely used in plumbing for decades due to its reliability and ability to withstand high temperatures. PEX tubing, made from cross-linked polyethylene, offers flexibility, ease of installation, and resistance to scale and chlorine, making it a popular alternative in modern plumbing systems. Both materials provide efficient water delivery solutions, but their distinct properties cater to different installation needs and budgets.

Material Composition: Copper vs. PEX

Copper piping is made from natural copper, known for its durability, corrosion resistance, and ability to withstand high temperatures and pressures, making it ideal for long-lasting plumbing systems. PEX tubing consists of cross-linked polyethylene, a flexible plastic material that resists scale buildup and chlorine, offering easy installation and resistance to freezing. The fundamental difference in material composition affects their performance, cost, and application suitability in residential and commercial plumbing.

Durability and Lifespan Comparison

Copper piping offers exceptional durability with a lifespan typically exceeding 50 years, resisting corrosion, high temperatures, and UV exposure. PEX tubing, while flexible and resistant to scale and chlorine, generally has a shorter lifespan of 25-40 years and can degrade with prolonged UV exposure. The choice between copper and PEX depends on factors such as environmental conditions, installation requirements, and long-term maintenance expectations.

Installation Process and Flexibility

Copper piping requires soldering and special fittings during installation, demanding skilled labor and longer setup times. PEX tubing offers superior flexibility, allowing it to bend around corners and obstacles without additional fittings, which simplifies and speeds up the installation process. Its ability to expand reduces the risk of burst pipes in freezing conditions, making it a versatile choice in various plumbing scenarios.

Cost Analysis: Copper Piping vs. PEX Tubing

Copper piping typically incurs higher upfront costs due to its material price and labor intensity, averaging $2 to $4 per linear foot, whereas PEX tubing ranges from $0.50 to $2 per linear foot with easier installation reducing labor expenses. Over time, PEX offers cost savings in maintenance and repair because of its flexibility and resistance to corrosion, unlike copper which may require more frequent upkeep in certain water conditions. Despite higher initial investment, copper can provide longer lifespan and better durability in extreme temperatures, influencing overall cost-effectiveness depending on application and regional price variations.

Resistance to Corrosion and Chemical Reactions

Copper piping exhibits excellent resistance to corrosion due to its natural oxide layer that protects the metal from further deterioration, making it highly durable in plumbing applications. PEX tubing, made from cross-linked polyethylene, is inherently resistant to chemical reactions and does not corrode, but it can be susceptible to degradation from prolonged exposure to UV light or certain chemicals. Both materials offer distinct advantages in corrosion resistance, with copper excelling in longevity in aggressive water conditions and PEX providing superior resistance to chemical leaching and scale buildup.

Water Quality and Health Considerations

Copper piping naturally inhibits bacterial growth and leaches trace amounts of copper ions, which can offer antimicrobial benefits to drinking water. PEX tubing maintains water quality by resisting scale buildup and corrosion, preventing harmful contaminants associated with metal pipes. Both materials meet health and safety standards, but copper's innate antimicrobial properties provide a distinct advantage in water purity.

Repair and Maintenance Requirements

Copper piping requires periodic inspection for corrosion and potential leaks, with repairs often involving soldering or section replacement, which demands skilled labor. PEX tubing offers easier maintenance due to its flexibility and resistance to scale and corrosion, allowing quick repairs using simple crimp or clamp fittings. Overall, PEX reduces long-term maintenance costs and downtime compared to copper piping systems.

Environmental Impact and Sustainability

Copper piping, known for its durability and recyclability, offers significant environmental benefits through its natural antimicrobial properties and near 100% recyclability, reducing landfill waste. PEX tubing, derived from non-renewable petroleum resources, presents challenges in recyclability and potential chemical leaching, impacting long-term environmental sustainability. Evaluating the carbon footprint, copper production is energy-intensive but offset by its longevity and recyclability, whereas PEX relies on fossil fuels with limited end-of-life recycling options.

Choosing the Right Piping Material for Your Project

Copper piping offers excellent durability and natural antimicrobial properties, making it ideal for long-term plumbing installations; it withstands high temperatures and resists corrosion in most environments. PEX tubing provides flexibility, ease of installation, and cost-effectiveness, often preferred for residential projects and retrofit applications due to its resistance to scale and chlorine. Selecting the right piping material depends on project requirements such as budget, water quality, climate conditions, and local building codes affecting performance and longevity.

Copper Piping vs PEX Tubing Infographic

materialdif.com

materialdif.com