Phosphorized copper contains a small amount of phosphorus, which improves its strength, wear resistance, and corrosion resistance, making it ideal for applications requiring durability and solderability. Deoxidized copper, also known as oxygen-free copper, is produced by removing oxygen during melting to prevent porosity and improve electrical conductivity, crucial for high-performance electrical components. Both types serve distinct industrial purposes, with phosphorized copper favored for mechanical robustness and deoxidized copper chosen for superior electrical performance.

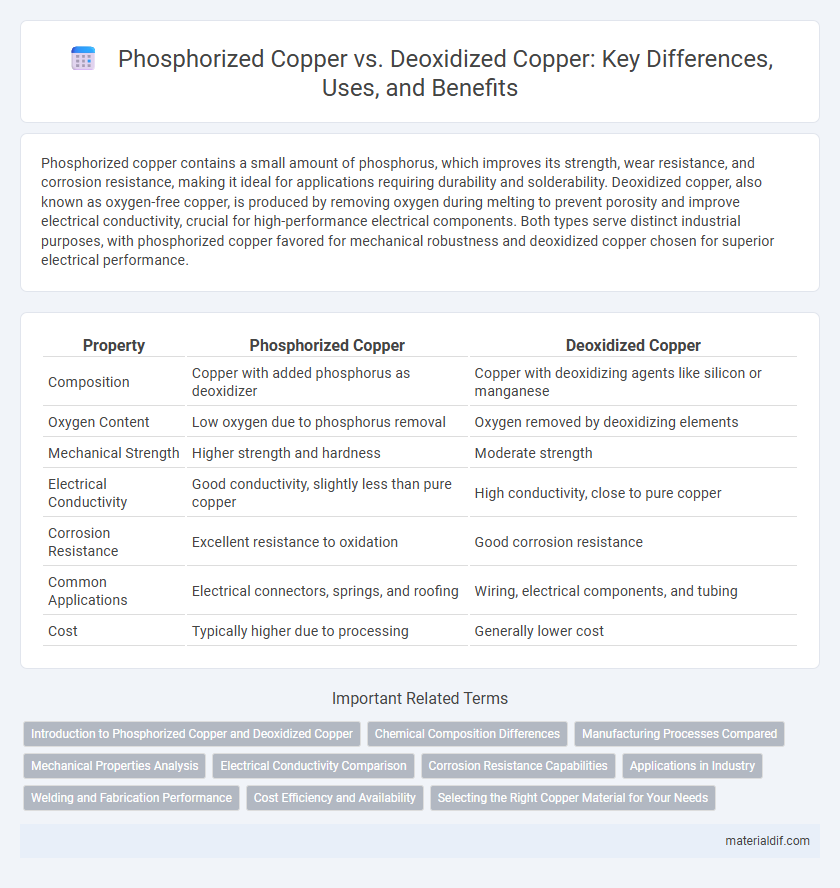

Table of Comparison

| Property | Phosphorized Copper | Deoxidized Copper |

|---|---|---|

| Composition | Copper with added phosphorus as deoxidizer | Copper with deoxidizing agents like silicon or manganese |

| Oxygen Content | Low oxygen due to phosphorus removal | Oxygen removed by deoxidizing elements |

| Mechanical Strength | Higher strength and hardness | Moderate strength |

| Electrical Conductivity | Good conductivity, slightly less than pure copper | High conductivity, close to pure copper |

| Corrosion Resistance | Excellent resistance to oxidation | Good corrosion resistance |

| Common Applications | Electrical connectors, springs, and roofing | Wiring, electrical components, and tubing |

| Cost | Typically higher due to processing | Generally lower cost |

Introduction to Phosphorized Copper and Deoxidized Copper

Phosphorized copper contains a small amount of phosphorus, which improves its wear resistance, corrosion resistance, and strength, making it ideal for applications like electrical contacts and plumbing. Deoxidized copper is treated with deoxidizing agents such as phosphorus or silicon to remove oxygen, enhancing its conductivity and reducing porosity, which is crucial for high-quality electrical and electronic components. Both types optimize copper's properties for specific industrial requirements, balancing mechanical strength and electrical performance.

Chemical Composition Differences

Phosphorized copper contains a small percentage of phosphorus, typically around 0.01% to 0.05%, which acts as a deoxidizing agent and improves the metal's strength and corrosion resistance. Deoxidized copper, also known as oxygen-free copper, has very low oxygen content, generally less than 0.02%, achieved by adding elements like phosphorus or other deoxidizers during melting. The key chemical difference lies in phosphorus content, enhancing deoxidized copper's electrical conductivity while phosphorized copper benefits from increased hardness and durability.

Manufacturing Processes Compared

Phosphorized copper is manufactured through a copper-phosphorus alloying process involving the addition of phosphorus during melting, which improves wear resistance and machinability by forming copper phosphide inclusions. Deoxidized copper, also known as oxygen-free copper, is produced by adding deoxidizing agents such as phosphorus or silicon to molten copper to remove dissolved oxygen, enhancing electrical conductivity and reducing porosity. The manufacturing process of phosphorized copper emphasizes alloy formation for mechanical strength, while deoxidized copper focuses on oxygen removal to achieve superior electrical and thermal properties.

Mechanical Properties Analysis

Phosphorized copper exhibits enhanced mechanical properties such as increased tensile strength and improved hardness compared to deoxidized copper, making it suitable for demanding applications requiring durability. The addition of phosphorus refines the grain structure, resulting in better creep resistance and reduced brittleness under thermal stress. In contrast, deoxidized copper offers higher electrical conductivity but generally has lower mechanical strength and wear resistance.

Electrical Conductivity Comparison

Phosphorized copper contains a small amount of phosphorus, which enhances its resistance to oxidation and improves mechanical strength while slightly reducing electrical conductivity compared to pure copper. Deoxidized copper, also known as oxygen-free copper, undergoes a process to remove oxygen, resulting in higher electrical conductivity and superior thermal performance ideal for electrical applications. In terms of electrical conductivity, deoxidized copper typically achieves values close to 100% IACS (International Annealed Copper Standard), whereas phosphorized copper exhibits slightly lower values due to phosphorus content impacting electron flow.

Corrosion Resistance Capabilities

Phosphorized copper exhibits superior corrosion resistance due to the presence of phosphorus, which enhances its ability to withstand oxidation and reduces the formation of copper oxide layers. Deoxidized copper, while effective in minimizing oxygen content to prevent internal flaws, generally offers lower corrosion resistance compared to phosphorized copper in aggressive environments. The improved durability of phosphorized copper makes it ideal for applications exposed to moisture and chemical agents.

Applications in Industry

Phosphorized copper, known for its enhanced strength and corrosion resistance, is widely used in electrical components, plumbing, and heat exchangers, where durability and conductivity are crucial. Deoxidized copper, with its high purity and minimal oxygen content, is preferred in electrical wiring, transformers, and electronic circuits for superior electrical conductivity and reduced risk of oxidation. Industrial applications leverage phosphorized copper for mechanical robustness and deoxidized copper for optimal electrical performance.

Welding and Fabrication Performance

Phosphorized copper offers superior welding performance due to its improved fluidity and reduced oxidation, enabling cleaner welds and stronger joints. Deoxidized copper contains minimal oxygen, which minimizes porosity during welding but may require careful control of welding parameters to prevent defects. In fabrication, phosphorized copper provides enhanced machinability and durability, while deoxidized copper excels in maintaining electrical conductivity and corrosion resistance.

Cost Efficiency and Availability

Phosphorized copper offers enhanced corrosion resistance and improved mechanical strength, making it slightly more expensive but cost-efficient in long-term applications where durability matters. Deoxidized copper, being more readily available and less costly to produce, provides good conductivity and ease of fabrication, appealing for high-volume, budget-sensitive projects. The choice between these types hinges on balancing upfront material costs with performance requirements and supply chain availability.

Selecting the Right Copper Material for Your Needs

Phosphorized copper offers enhanced strength and corrosion resistance, making it ideal for applications requiring durability and thermal conductivity, such as electrical connectors and heat exchangers. Deoxidized copper, with its high purity and excellent electrical and thermal conductivity, is preferred for sensitive electronic components and wiring where minimal impurities are crucial. Choosing between phosphorized and deoxidized copper depends on balancing mechanical strength and conductivity requirements specific to your industrial or electronic project.

Phosphorized Copper vs Deoxidized Copper Infographic

materialdif.com

materialdif.com